DIY garage roof

A dry and reliable garage can only be built if the roof is correctly and properly installed. Its presence will save the car from the negative effects of the environment and bad weather. Car owners are not particularly puzzled by the complex forms of garages and prefer reliable and simple designs. The most popular are single-pitched roofs, but today there is already a tendency to create gable roofs for garages. Do-it-yourself garage roof is erected quickly enough, the main thing is to adhere to certain rules and recommendations.

Content

- Standard roof design

- Garage Roof Device

- Construction of a pitched roof

- Gable roof construction

Standard roof design

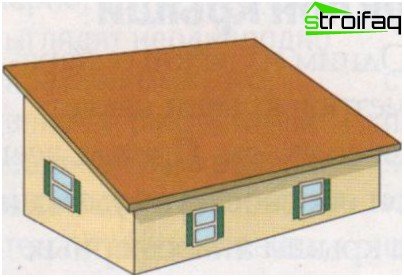

Before you make the roof of the garage, you need to decide what the roof will be – single-pitched or gable. They differ among themselves in design, complexity of work, the amount of required material and the ability to equip a full attic.

Garage roof arrangement

Gable Roof equips when the garage is adjacent to other buildings, or is part of them. For such a design, inclined hanging rafters are installed, which are supported by two supports. For a stable and solid construction, the dimensions of the garage must be taken into account. If its width will be no more than 4.5 m, then the rafters are laid on supports at a certain angle and fixed there. This design is considered simple. The complicated design of rafters of a single-pitch roof is used in the case when the distance between the supports is from 4.5 m to 6 m. For this design, it is necessary to install struts that will strengthen it.

Gable Roof It is advisable to install for free-standing garages. Such a roof is an isosceles triangle. It can be installed for garages of any size, the main thing is to correctly calculate the angle of inclination. The rafter structure consists of two rafter legs, interconnected at the highest point. Rafters lean on load-bearing walls.

Installing a gable roof with a do-it-yourself garage is quite simple. But in order to facilitate the performance of work, they must be performed by two or three.

Garage Roof Device

Regardless of the type of roof, it consists of rafters, battens, roofs, heat and waterproofing. Each of these elements is equipped in due time. For the installation of single-pitched and gable roofs, there are rules and calculations that must be done before starting work.

Construction of a pitched roof

The slope of the shed roof is selected depending on the roofing material

As previously noted, the shed roof is an inclined structure, the ends of which are supported by two supports. In order to properly build such a roof, it is necessary to calculate the height difference of the walls on which it will be based. The angle of inclination is selected depending on the material that we will use. The difference is calculated by the following formula:

H = b * tan “a”;

Where, b – the width of the garage, “a” – the angle of inclination (slope) of the roof.

Now you can proceed with the installation of the truss structure:

- on the supporting walls we lay Mauerlat (support beams with a section of 120×120 mm or 100×100 mm);

- we fix the Mauerlat to the walls with anchor bolts;

- in the rafters at the junction with the Mauerlat, we cut down the mounting nests;

- we put the rafters in place and fasten with anchors or nails;

- on top of the rafters we install a wooden crate.

Important! Quite often, a shed roof is made of concrete floor slabs. The slope of such plates is up to 15 °, and it is advisable to lay a soft roof on them.

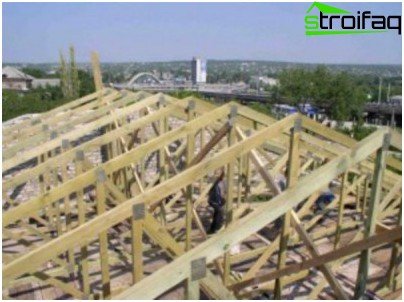

Gable roof construction

To equip a gable roof, we install rafters with an isosceles triangle

The gable roof is an isosceles triangle: the rafters are connected in the “ridge” (the top point of the roof), the length of the rafters is the same. To build such a roof, it is necessary to calculate the length of the rafter leg and the height of the ridge. To do this, we use the following formula:

The height of the roof ridge H = 0.5 * b / tan (“a” 2);

Rafter leg length C = 0.5 * b / sin (“a” / 2);

Where b is the width of the garage; “a” – tilt angle.

Important! To make the visor protruding beyond the structure, it is necessary to add another 50 cm to the length of the rafter leg.

To create a gable roof, you must perform the following work:

- on the walls around the perimeter of the building we put Mauerlat and fix them;

- rafters are made according to the template. To do this, we take boards equal in length to the distance between the Mauerlat. One of them is laid on the Mauerlat, the other two are set at an angle so that they meet in the ridge. Then, strictly in the middle, we establish a perpendicular support equal to the height of the ridge. We fasten the boards together, driving nails into them or screwing screws. We should get a rafter template. We cut the rest of the rafters along it;

Important! To be able to adjust the pattern, rafters from the boards do a little more than required.

- when everything is ready, first we install the extreme pairs of rafter legs and fix them with anchors;

- pull the cord at the level of the ridge for the accuracy of the installation of the following rafter legs;

- install the remaining rafters in increments of 0.7-1.2 m;

- on the rafters we fill the crate from wooden boards 25×30 mm.

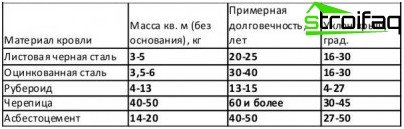

How and how to equip the roof

Before you build the roof of the garage, you should choose the material for the roof. There are no difficulties with choosing roofing materials on the market, but the angle of the roof depends on what type of material will be used. To know how to properly make a garage roof with a securely laid roof, it is necessary to take into account the minimum and maximum angle of inclination of the rafter structure. Another important point for arranging rafters is the mass of the roof, the larger it is, the more thick rafters will have to be used. Table No. 1 shows the dependence of the angle of the rafters on the type of roofing material.

Table number 1. The dependence of the slope of the roof (slope) on the type of roof

Usually, preference is given to a particular material depending on its availability and ease of installation. The most common materials for the roof of the garage are roofing material, corrugated board, galvanized metal, slate (asbestos-cement sheets). Using these materials, you can independently perform all roofing work..

Roofing roofing

Roofing roofing in several layers – the best option for pent roofs

This is one of the most common and affordable roofing materials. Laying roofing material should be done on a solid base. It can be a concrete slab or a solid wooden crate. Due to its qualities, ruberoid has a dual function – it creates a continuous inexpensive coating and protects against rain.

Ruberoid belongs to the soft roofing materials of the roll type, which facilitates its installation. To make a high-quality roof of the garage with the help of roofing material, it is necessary to lay it in two or three layers. The first layer will be lining, and the subsequent ones will already be the main roofing. To create a high-quality roof from roofing material it is necessary to perform the following stages of work:

- First of all, it is necessary to create a basis for the roof;

- then we coat the base with bituminous mastic and lay the first layer of roofing material. To perform the work efficiently, it is necessary to coat the surface with bituminous mastic just before laying and then roll out and press the roofing material;

Important! It is necessary to spread with bitumen along the entire width of the roofing material roll with a slight indentation for the subsequent canvas. Cloth roofing material must be overlapped, with an advance of 15-20 cm. The next point is especially important – start laying roofing material must be from the bottom up in the direction of the roof. Thanks to this installation, water will not flow into the joints and cracks between the sheets.

- the next layer of roofing material is laid in a similar way. The only difference will be the laying direction – perpendicular to the direction of the first layer;

- finally, we coat the resulting roof once again with bituminous mastic over the entire area.

In addition to roofing material, there are other soft roofing bitumen and polymer-bitumen multilayer materials of a roll type. They can be laid on bitumen mastic or using a gas burner. The second method requires increased attention to work and is very fire hazard.

Slate laying, specifics

Slate roofing – the most common option

Slate, as a roofing material, is widespread due to its low price, availability and durability. A roof made of this material is easy to operate and can last about 40 years. Slate is laid similar to corrugated board, but in contrast to it, slate has a large mass and requires a strong and reliable rafter structure. For rafters, wooden bars with a cross section of 80×100 mm should be used. Thermal insulation and waterproofing of slate roofs is carried out by analogy with corrugated board.

Metal garage roof

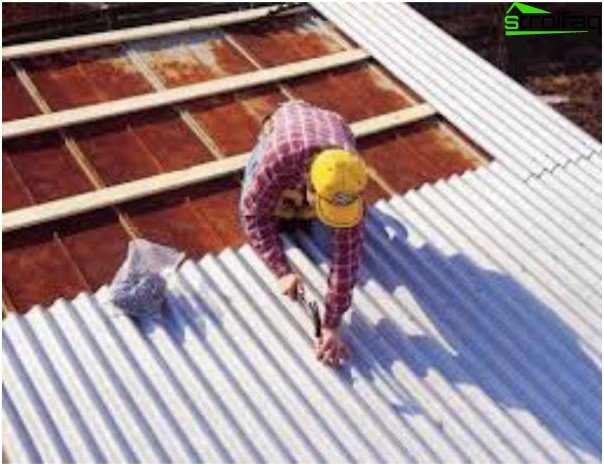

Corrugated roofing – a modern option

This type of roof is one of the lightest in weight, which to a large extent allows you to save on the arrangement of the rafter frame and lathing. To create rafters for metal, it will be enough to use bars with a section of 50×50, 30×50 or 30×100 mm. Which one of them to use will depend on the load on the rafter structure.

To create a high-quality metal roof, it will have to be insulated and waterproofed. Thermal insulation in such a roof is laid between the rafters, and waterproofing materials directly under the roofing. To create such a roof, you must do the following:

- create a rafter frame and a crate of wood;

- we put waterproofing on the surface of the crate. For these purposes, you can use a plastic film 200 microns thick. The film itself is fixed to the crate with the help of thin rails with a section of 20×20 mm, we make the fastening step of the rails 50-70 cm;

Important! If corrugated board is used as the roofing material, then we select the step for the battens so that the corrugated sheet rests tightly on them.

- on top of the waterproofing we lay a metal roof. We fix the corrugated board to the crate with the help of special screws, for convenience, having previously drilled a small hole in the metal and wood;

- Such a roof should be insulated from inside the garage. We lay the insulation between the rafters and fix it with thin rails.

Important! The insulation must be cut and laid so that there are no cracks and gaps between the parts of the insulation and the rafters.

If we plan to lay a classic rebated galvanized roof, then we can not do without a special tool and certain skills. If you can do it yourself to create a roof from corrugated board, then for a rebated roof you will have to invite a professional roofer, which will entail additional costs.

Regardless of the type of roofing materials and the type of roof, all work should be done with great care and attention to detail. The roof of the garage must be strong and reliable in order to protect the car from various atmospheric precipitations and their destructive effects. The construction of the roof of the garage requires quite a lot of labor, so the help of a partner will be very useful.