Do-it-yourself garage doors

To make a garage door with your own hands means significantly saving on the purchase and installation of a finished construction. Not surprisingly, this prospect seems quite attractive to many craftsmen. However, to realize this venture in life is far from as simple as it might seem. To make really high-quality, beautiful and reliable garage doors, you will have to make a lot of effort. Moreover, they should be based on knowledge of all the features of assembly technology.

Content

- Structural types of garage doors

- Garage Door Requirements

- How to make a garage door

- We buy tools and materials

- Making a mounting frame

- Fabrication of the frame (lathing)

- Door trim – responsible work

- Upper and lower hinges

- Installation of locks and locks

- Garage door painting

- Installation by stages

- Warming garage door gates

- Repair and modernization

Structural types of garage doors

Initially, it is necessary to determine and choose the type of construction of the garage door. There are several of them:

1. Swing. The most ancient type of gate. They gained popularity due to the convenience, simplicity of the design, consisting of two leaf leaves, and also due to the relative “low cost”. In addition, it is easiest to make them yourself..

2. Rotary lifting. When opening the door leaf rises to the ceiling vertically. They are based on the articulated lever mechanism. The gates are quite practical and comfortable, do not take up space either in front of the garage or inside it.

3. Sectional. The design provides for a canvas consisting of sections. When opened, they are refracted, rising to the ceiling using a special spring mechanism and a profile system. Important advantages of such doors are good tightness and space saving..

4. Retractable. Open as a wardrobe, i.e. shift to the side.

five. Roller. They are similar to roller shutters. Plate plates are folded under the ceiling in a special box.

Garage swing gates

As mentioned above – swing gates are easier to manufacture and cheaper than the rest, therefore it is the technology of their assembly, as the most acceptable option for most, we will consider. It is more difficult (although quite possible) to make up-and-over and sliding gates. They will have to buy lifting gear without fail, which will cost significantly more.

On sale there are special kits for self-assembly of such gates with the attached instructions. Sectional and rolling shutters for a garage are better to buy factory and order installation from experts.

Garage Door Requirements

When creating a home-made structure, it is important to know that high-quality doors must meet certain requirements, namely:

1. Provide easy, unimpeded entry / exit. Their sizes should be optimal in accordance with the dimensions of vehicles.

1.1. The distance from the side of the car to the goalpost should not be < 30 cm. If the car is small, then try to increase this distance as much as possible (in case you decide to buy an SUV).

1.2. For ordinary cars, the door height of 2 meters is considered optimal.

1.3. Standard sizes of garage openings: from 2, 4 x 2.1 to 5.4 x 2.4 m.

2. To have resistance and breaking resistance. The most durable will be a garage door made of galvanized steel sheet no thinner than 2-5 mm. The gates can be strengthened with overhead locks designed for external pads, also using armored plates used for internal locks.

3. Provide protection against the harmful effects of the environment. Protection from the wind, rainfall should be ensured by the fastening of the garage door. For strong fixing of a cloth vertical locks which are capable to prevent a warp of a gate should be applied. It is also recommended to use a sealant (it will provide optimal contact between the wings and the frame).

The gates must provide free, trouble-free patency of the machine

How to make a garage door

We buy tools and materials

Materials:

1. Steel corners for the manufacture of a bearing (fixing) frame

2. Sheathing (corrugated board, forging, wood or metal sheet at your discretion).

3. Gate valve

4. Profile (for example, 60×30 or 60×20)

5. Loops

Instruments:

1. Roulette

2. Bulgarian

3. Level

4. Square

5. Welding machine

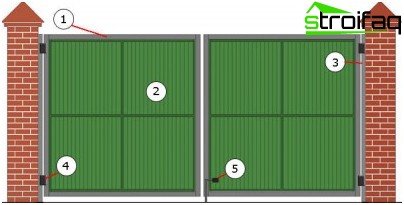

Components of swing gates: 1. metal frame; 2. casing; 3. racks; 4. loops; 5. gate valve

Making a mounting frame

The bearing (fixing) frame is made of a steel corner. It consists of 2 parts – the internal as well as the external frame.

1. First you need to measure the height and width of the opening. The accuracy of measurements is important, on which the installation of the finished frame will depend .

2. Then from the corner with a square section (with sides from 160 to 200 mm) measure and cut the necessary blanks for the outer frame.

3. Lay them out on a flat plane, set the level horizontally (it is regulated by pads) and align the angles. Adjust all right angles by measuring the diagonals. Thus, on a flat surface, it is necessary to lay out the blanks in the exact shape of the future frame.

4. Weld the frame. So that in the future the gates to the frame fit as tightly as possible, its outer side must be completely flat and smooth. To do this, grind all welds with a grinder.

5. Next, in the corners, it is necessary to weld the vertical “levers” (for this, corner trimming is suitable). This is necessary in order to provide spatial rigidity (i.e., geometric immutability) of the frame. In this case, the corner will not lead.

Garage door construction elements need to be laid out on a plane or level

Fabrication of the frame (lathing)

The frame is necessary for two swing open sashes. Subsequently, a metal web will be attached to them. In the manufacture of the frame, you can use a profile of 60? 20 mm.

1. Lay the garage pipe frame face up on a flat surface..

2. Insert the guides into the frame, while carefully aligning the location of each side.

3. Make a gap between the frame and the frame (? 20 mm) using the inserts. This is necessary for the free movement of all wings.

4. Then you should carefully check the right angles of the frame and weld the profiles weld.

For the manufacture of crates, a metal profile is predominantly used.

Door trim – responsible work

This is a very important and crucial stage, the appearance and functionality of the design will largely depend on the quality of its execution..

It is especially important here to know how to weld the garage door correctly. So, the sequence of actions:

1. Trim the galvanized iron sheet to the size of the wings. Please note that the left wing should overlap by 1 or 2 cm on the profile of the right wing.

2. Weld the sheet in several places below (to fix it on the frame).

3. Trim the casing of the right wing, which will be already about 1-2 cm left (that is, the iron sheet will not reach this distance to the edge of the profile).

4. Cook. To prevent the sheet from moving during welding on the frame, it is necessary to weld it in the middle and at the corners of each side of the garage box. At the end of the work, these points are cut off. Otherwise, one of the corners of the canvas may bend out. It will be possible to fix this only by applying a sledgehammer.

Cladding Garage Works

Upper and lower hinges

Hinges must be prepared in advance. The lower part of the hinge must be welded to the frame, and the upper part is welded to the outer sash. You can cut and bend a strip of metal (5-7 mm), thus strengthening the connection. It is applied to the top of the hinge, as well as to the gate wing. To strengthen the strength of the hinges, a reinforced tab on the inside is suitable.

Installation of locks and locks

Garage doors usually have either a mortise lock or a padlock. It is also advisable to use a powerful deadbolt and pin stoppers. With their help, you can close the door from the inside, but at the same time you need another door in the door leaf, or in the wall of the garage.

Design of stoppers: a piece of pipe is driven into the ground, into which the movable part of the stopper is immersed – a rod. It is threaded through the hinge in the gate leaf. The pipe of this design must be constantly monitored, otherwise it may become clogged with dirt and snow..

Garage locks need careful, timely care. They must be protected from moisture (especially in frosty winter). When frozen, moisture will prevent the key from entering the keyhole. Most others are subject to freezing locks on a garage with a cylinder mechanism. Better to use locks with a tubular key.

Also, locks should be lubricated, at least with ordinary graphite powder from a pencil or spindle and transformer oil. When using graphite powder, the core must be removed from the pencil, rubbed, then blown into the keyhole.

Garage door painting

Paint the gate, mainly in order to protect the canvas from destructive factors: damage, corrosion. First they are primed, then in 2 layers paint is applied on the metal.

Installation by stages

Gate installation – the final stage

1. First, the inside and outside of the frame are installed. Attached to the slopes of the opening using metal pins 15-18 cm.

2. Then, the protruding ends of the pins are cut off, scalded, polished carefully with a grinder (so that they do not prevent the door from closing), are painted over.

3. The outer, inner frames are fastened together by plates of metal (jumpers) of 4 cm. The plates are welded every 60 cm.

4. This stage ends with hanging the wings.

If desired, the swing structure can be equipped with automation, as in the video example of the gate that encloses a personal area:

Warming garage door gates

If the metal gates are not insulated, then up to 60% of the heat will leave the heated garage through them. Therefore, they must be insulated by installing a wooden crate on the inner surface of the wings. Insulation is placed inside it – mineral wool, glass wool or PSB-S polystyrene foam. It is important not to leave any air spaces, carefully filling the gaps. A five-centimeter layer of insulation will be enough. From above, the crate should be covered with facing plates or lining. Can also hang a canvas or plastic curtain from the inside..

Repair and modernization

Sometimes during operation, you may need to adjust the location of the garage door.

1. For example, if the opening / closing of the wings is difficult due to their too low location. In this case, the easiest way to solve the problem is to trim the bottom of the wings with a grinder..

2. It may happen that the opening height is no longer suitable for the dimensions of a new machine. It will have to spend more effort than in solving the first problem. The method is applicable only for brick garages: 1-2 rows of masonry should be knocked out above the opening, then the slope should be strengthened, then the frame should be raised to this height.

As you can see, constructing a makeshift garage door is more than realistic. However, a lot of effort and knowledge will have to be made. It is necessary to have at least a minimum set of building skills and abilities in order to make really high-quality gates that will be distinguished by quality and will last a long time..