Basement waterproofing

Since the time of the construction of communism in our country, it has been customary to arrange a basement in the garage. It is necessary in order to store products: vegetables and fruits grown in summer cottages. Residents of high-rise buildings simply have no other opportunity to store the crop grown with such difficulty. The construction of the basement is a very responsible business. If you do not follow the technology, you can create ideal conditions for the life of pathogenic flora. Despite the fact that for a successful and long-term storage of vegetables in the basement there must be a certain sufficiently high humidity, nevertheless, everything should be in moderation. If mold or other fungi settled in the basement, then goodbye to the harvest. That is why basement waterproofing is the most important stage of its construction..

Content

- How to protect the basement from water

- Basement floor waterproofing

- So that the walls do not let water through

How to protect the basement from water

This article will tell you how to properly waterproof the basement during the construction phase. And the question of what to do if you become the happy owner of a garage with a basement without waterproofing will also be raised..

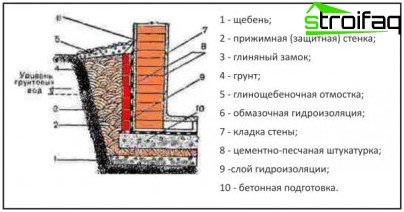

Basement waterproofing scheme if the groundwater level is higher than the floor or basement walls

Basement waterproofing is divided into several types:

Pressure waterproofing – waterproofing the basement from groundwater, the level of which is higher than the level of the basement floor or even its walls. It is a pie of at least 3 layers of slurry solutions that are combined with mastics based on polymer bitumen.

Non-pressure basement waterproofing protects it from moisture that has accumulated after precipitation or floods. It consists in applying bituminous mastics to the floor surface..

Anticapillary waterproofing protects against penetration of moisture through the concrete floor or wall, which can rise up through the capillaries. In addition to anti-pressure waterproofing measures, seams, cracks and capillaries are insulated.

Basement floor waterproofing

Basement floor waterproofing scheme

Qualitatively isolate the floor only at the construction stage. There are techniques for isolating the floor during the operation of the finished garage, but waterproofing from the inside will not be enough. Therefore, if you decide to build a basement in a garage or house, you must perform the following work:

- We calculate the depth of the pit, which must be dug. For this, we take into account the height of future ceilings in the basement, the height of the ceilings, the thickness of the concrete floor and the preparatory layer. Most often, the basement ceiling in the garage is buried below the level of soil freezing, approximately by 0.5-1 m. Thus, the depth of the pit should be 3.3-3.5 m.

- We dig a pit not only to the required depth, we retreat at least another 1 m from the future foundation and walls to equip the walls with waterproofing.

- Level the surface, making a slight bias from the middle in different directions. We fill in a 10 cm layer of clay and ram. In the future, it will serve us as a clay castle..

- We dig out drainage trenches. Depth 30-50 cm. We give them biases to the sides of the structure.

- We spread geotextiles at the bottom of the trench, wrapping it over the edges of the trench 80-90 cm.

- We fill a 5 cm layer of gravel along the entire length of the trench.

- We lay down the drainage pipes, making a slope of 0.5 cm per 1 meter.

- We fall asleep a 20-30 cm layer of gravel, which is previously best rinsed so as not to clog the pipes.

- Wrap the remaining geotextiles. We bring out drainage pipes either in manhole, either in the drain manifold or in the pit.

We fill the drainage ditches with gravel and wrap it with geotextile

Important! Drainage is necessary in order to collect and divert drained water to special places (wells). For it, you can use special perforated asbestos cement pipes, ceramic or plastic.

10. In a foundation pit we fill up a 10-15 cm layer of crushed stone, from above 10-15 cm of sand. Ramming.

Important! Sand is necessary in order not to damage the roll waterproofing with sharp edges of crushed stone.

11. On a prepared base we roll out some roll waterproofing. A roofing material is suitable. We weld the joints with a gas torch. We coat the first layer with bituminous mastic, lay the next layer. A minimum of 2 layers must be made. If the groundwater level is above the basement floor, then there should be 3-4 layers.

Important! If the basement is made to store food, then there is no need to insulate its floor. Cooling from the ground in the cold season will provide the necessary temperature. In this case, you will have to insulate the floor of the first floor.

12. We prepare the formwork for the floor and pour concrete.

Important! It is advisable to use waterproof hard concrete mixes. It will not be superfluous to fill the walls with concrete, but it is quite possible to use red brick.

If you are interested in the question of how to waterproof the basement when it is already built, then you will read the answer below. You only have to waterproof the walls from the outside and from the inside..

The outer wall of the basement will have to be dug to the depth of almost the entire basement and a clay castle and blind area should be equipped.

So that the walls do not let water through

If you decide to build the walls of brick, then we perform the usual masonry. If you decide to make concrete, then we prepare the formwork for the walls and pour concrete.

Important! Silicate brick is not suitable for building a basement.

Further waterproofing the basement with your own hands looks like this:

- We plaster the walls on both sides with mortar: 1 part cement + 2 parts water.

- Glue roll waterproofing in two layers.

- We build an outside clamping wall. It can be made of red brick into one brick.

Important! The pressure wall is necessary in order to support and protect the roll waterproofing layer.

4. We carry out the clay castle at a distance of at least 0.5 m from the wall. We do it with a bias, as shown in the figure. The clay layer should be 100 mm, we seal it with wooden blocks. This layer should coincide with the clay layer under the floor so as to be one piece.

Important! Clay lock prevents groundwater from contacting the pressure wall.

5. We fill the space between the clay castle and the wall with soil. From above we make the clay-brick blind area. We make a slight slope from the walls so that rainwater does not flow down under the basement, but in the other direction.

6. The outer part of the wall, protruding above the ground, is treated with coating waterproofing.

On this, all work on waterproofing the walls of the basement from the outside is completed, you can proceed to the internal work..

We isolate the built basement from the inside

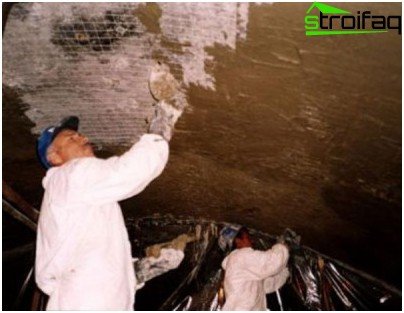

First of all, we coat all the joints between the floor and the walls with bitumen mastic. It is advisable to pre-treat concrete structures (floor or floor and walls) with penetrating waterproofing in order to improve the effect. But these works need to be carried out only while concrete has not yet hardened to the end. If the work is carried out in an already finished basement, then the floor is only smeared with mastic.

For waterproofing the basement from the inside, coat with bitumen mastic and plaster with a cement mixture

If the walls are made of brick or blocks, between which there are cracks, we coat all the cracks with waterproofing mastic 2 cm thick.

Then it can be coated with light texture mastic. The wall will get a uniform color..

From above we plaster the wall with a cement mixture. To give rigidity, we fasten the frame from the reinforcement to the wall. Then plastered with a layer of 3-4 cm.

For good preservation of products in the basement, its walls can be treated with biologically resistant coatings..

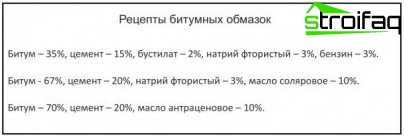

Bitumen can be taken of any grades, and cement is only waterproof. We melt the bitumen at a temperature of 1500-1700 ° C, add the remaining components according to the recipe, mix for 20 minutes and use while hot.

Biologically resistant coatings for bitumen treatment

On this waterproofing the basement from the inside with your own hands is completed. Next, we consider a little more materials for waterproofing.

Penetrating basement waterproofing

Penetrating waterproofing blocks the rise of water through the capillaries

Penetrating waterproofing is a material made from a mixture of cement, chemical active substances and fine sand. The substance penetrates deep into the walls and floor by 100 mm and crystallizes inside. This is due to the fluid structure and small grain size..

Important! Penetrating waterproofing is used as anti-capillary insulation. Hydrophobic crystals form inside the concrete, preventing water from rising through the capillaries.

In addition, the frost resistance of concrete is increased and its corrosion is prevented. This technology has an antibacterial composition, non-toxic, which makes it possible to use it in cellars with food.

Penetrating waterproofing differs by application method and penetration depth.

For example, “Hydrotex” penetrates up to 100 mm, is applied with a spatula, it is possible with a brush. Consumption: 3 kg / m2. Maximum strength 3 mm corresponds to the brand M 500. Has a double action.

Penetron penetrates up to 200 mm, is applied with a brush to a damp surface, a layer of up to 1-2 mm. The solvent is water. It closes the capillaries, preventing the penetration of water, but does not impede the movement of steam.

Important! Penetrating waterproofing is only used on wet concrete. The material processed by it is able to withstand any pressure of groundwater, its resource increases significantly.

Painting waterproofing, types

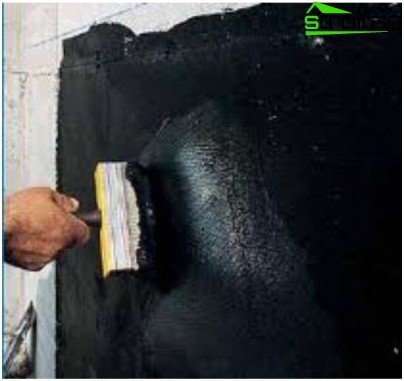

If the groundwater level is lower than the basement floor, bituminous, bitumen-polymer, polymer and polymer-cement mixtures can be used as waterproofing.

Bituminous mastics, pastes and emulsions are applied in several layers with a thickness of 2-6 mm.

As a bituminous waterproofing use bituminous mastics

Bitumen-polymer paint waterproofing is better than just bitumen in terms of performance due to the addition of polymers such as latex. The required layer ranges from 5 to 12 mm, depending on the composition.

Bitumen-nairite mastic (BNM) can be used at temperatures up to -15 ° C, it is enough to apply a layer of 3-4 mm.

Epoxy coatings are slightly plastic and shrink due to too clean resins in the composition.

Epoxy-tar waterproofing is stronger, has minimal shrinkage and does not freeze with the external ice during freezing of the building.

Epoxy-furan waterproofing is more toxic, although it requires a smaller layer.

Important! Epoxy-based waterproofing can be done both outside the basement and inside. Its significant disadvantage is too much stiffness..

Foam waterproofing with roofing material, roofing felt or other rolled materials is the most popular and has held its position for many decades.

The market offers a lot of tools and materials for waterproofing. Choosing them, you should pay attention to their characteristics and operating conditions. But the most important thing is to qualitatively perform waterproofing of the basement at all stages.