Pool waterproofing

Pools can rightfully be attributed to objects of increased complexity. Being hydraulic structures, they experience significant loads created by water. The water that fills the pool has an effect on the materials used, its frame, and ultimately destroys the design of the pool as a whole. That is why the waterproofing of pools is one of the most important stages of their construction..

It is worth noting that there are no special differences in the technology of waterproofing the pool from the waterproofing of other rooms with a high degree of humidity. However, it is necessary to take into account the fact that the materials used for these works vary greatly in composition and performance. So, the primer for pools has a special composition that allows you to apply it with a much thicker layer than usual.

Quite important is the question of the operational properties of the materials used to create the pool bowl. Among the designs, reinforced concrete, brick and monolithic options have gained particular popularity. For waterproofing this structure, elastic materials are often used that form a coating that repels water and prevents the appearance of cracks in the walls of the pool. However, along with them, cement-polymer compositions are also widely used..

Pool waterproofing – protection of construction materials from the damaging effects of water

It is no secret that the market of waterproofing materials constantly offers consumers new products of the most diverse, both domestic and foreign manufacturers. That is why it is recommended to carefully study this segment before choosing any specific material for pool waterproofing..

Content

- Types of waterproofing the pool

- Different ways to protect against water

- Bitumen based materials

- Penetrating waterproofing for pools

- Cement based insulation

- Liquid glass is an effective material

- Membrane waterproofing of pools

Types of waterproofing the pool

Today, pool waterproofing can be both internal and external. The latter is intended to protect this hydraulic structure from groundwater. Internal insulation prevents the negative effects of water on the pool bowl and protects it from leaks.

It is worth noting that the previously used materials for waterproofing pools, in particular, mastic, roofing felt, various polyvinyl chloride films, had poor adhesive properties. Moreover, rather high demands were placed on the insulated surface, for example, the humidity of the substrate was not allowed.

As for the external insulation, many materials that have become traditional for protecting pools from the negative effects of moisture work on separation, leading to the need to install additional retaining walls. This, in turn, leads to an undesirable increase in the cost of materials and work. That is why less expensive materials are used outside to protect the pool bowl from groundwater. However, the higher the groundwater level, the greater the need for good quality outdoor waterproofing of the pool. The fact is that groundwater, penetrating into the pores of concrete, can destroy reinforcement and all internal waterproofing, which will lead to deformation of the entire structure.

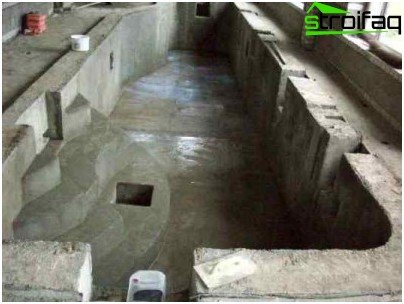

External waterproofing of pools is necessary to prevent groundwater

Internal waterproofing is designed to protect the entire pool structure from the damaging effects of corrosion. In addition, this type of insulation prevents peeling of the applied plaster, which leads to maintaining the strength of the pool and sealing its bowl. The fact is that the waterproofing of the pool bowl is one of the key points in the construction of this hydraulic structure. A number of mandatory requirements are imposed on the internal waterproofing of any pool:

- Good water resistance;

- The elasticity of the insulating layer;

- Subtlety of waterproofing;

- Crack resistance up to 3 mm;

- High degree of adhesion;

- The ability to withstand not only hydrostatic, but also dynamic loads;

- Suppression of the reproduction of microbes and various fungi;

- Environmental friendliness.

Internal pool waterproofing protects the bowl from corrosion and destruction

Different ways to protect against water

The technologies for performing waterproofing work are for the most part similar, and their main differences are determined by the waterproofing material used, each of which has its own application features.

Undoubtedly, a number of preparatory work will have to be carried out immediately before applying the insulating layer. The surface on which the waterproofing material will be applied should be as even as possible, there should be no cracks, chips or other defects on it. In addition, any contamination or residues of other coatings should be completely absent. Most often, such cleaning of the insulated surface is carried out by sandblasting.

Today, waterproofing a pool with your own hands can be carried out using a variety of compositions. These include:

- Mineral Acid Solutions Their main purpose is to open the pores of concrete, sufficient for the maximum penetration of the waterproofing composition into it.

- Polymerizable impregnation. They penetrate into concrete, polymerize, forming plastic. This type of impregnation allows you to strengthen the pool bowl made of concrete and create an excellent base for a layer of plaster.

- Additives to solutions. Among them, it is customary to include various grouts and adhesives that improve the waterproofing properties of concrete and other compositions.

As for directly the materials for waterproofing pools, then they are presented by manufacturers in a fairly wide range. It can be polymer membranes, liquid rubber, penetrating cementitious compounds, liquid glass and others. Each of these materials involves a specific technology for waterproofing.

Bitumen based materials

This type of waterproofing materials has become widespread more than 50 years ago, which allows us to rightly call it traditional. It was in the 60s of the last century that bitumen mastics, ruberoid and surfaced roll materials appeared on the market of insulating materials.

Bitumen-based waterproofing material

Today, these materials are practically not used for waterproofing pool bowls, as they are characterized by poor adhesion with those adhesive compositions that are used to install pool lining.

Penetrating waterproofing for pools

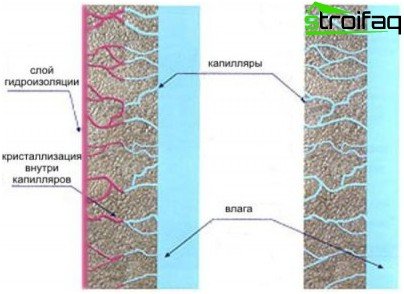

This type of waterproofing is based on the penetration of insulating material into the pores of concrete, where it polymerizes and clogs them reliably. The penetration depth of the composition can reach 0.5 m. A particular convenience when using this material is the possibility of applying it from the inside of an insulated structure. Penetrating waterproofing enhances the frost resistance of concrete and prevents mold and mildew.

The effect of penetrating waterproofing of the pool

It is worth noting that the waterproofing of pools with their own hands using penetrating compounds has a number of disadvantages. So, there is no possibility of isolating the joints of concrete and water supply equipment elements, sealing cracks that have occurred in the plaster layer.

Cement based insulation

Waterproofing materials based on a cement-sand mixture are two-component, since modified polymers are added to their composition. As a rule, the layer of such waterproofing has a thickness of 2-5 cm. The application of insulation is carried out in stages.

Cement-based waterproofing materials are superior in performance. They are ideal for insulating outdoor and indoor home pools. They are characterized by a high degree of adhesion to a wide variety of surfaces; they easily perceive dynamic and static loads.

Cement-based pool waterproofing

Such waterproofing materials, among other things, are notable for good vapor permeability, which allows you not to worry about the problem of bubbles and swelling. The reliability and durability of these materials are also quite high. The undoubted advantage of cement-based insulation is the convenience and ease of application. So, cement waterproofing can be applied even to wet surfaces..

However, it is necessary to note some disadvantages of these waterproofing materials. The biggest drawback is the low degree of elasticity, which leads to low material efficiency at temperature extremes, in places of stress concentration. The solution to this problem will be silicone or elastic sealants. The seams formed by these compounds will serve as unloading “belts”.

Liquid glass is an effective material

Currently, waterproofing of pools with liquid glass, which is a common aqueous solution of sodium silicate, has gained particular popularity. This solution allows you to increase the life of the pool several times, in addition, it compares favorably with antiseptic properties.

Waterproofing the pool with liquid glass

All pores and cracks in concrete are filled with liquid glass, which reliably protects it from corrosion and the destructive effects of moisture and air. Liquid glass has high adhesion to the applied surface, is fireproof. It can be used for waterproofing the pool in the form of impregnations, additives and additives.

Membrane waterproofing of pools

Membrane for waterproofing pools

Experts note that the membrane systems used to isolate hydraulic structures, in particular pools, work excellently in compression and tension, which allows them to easily withstand large tensile loads. However, working with membranes requires a special welding machine or hair dryer for welding seams. As a rule, this work is performed by qualified specialists, since poor-quality welding of the membrane will violate the integrity of the entire waterproofing layer. So, the presence of a small hole of 1-2 mm will lead to the fact that all the water filling the pool may be under a waterproofing coating.

Thus, today there are many different compositions and materials that are used to one degree or another for high-quality waterproofing of swimming pools, both indoor and outdoor. Solving the problem of how to waterproof the pool, it is necessary to carefully study the appropriate segment of the market of insulation materials, take into account your own preferences, the size of the pool, the material for its bowl, financial capabilities. Accounting for these nuances will allow you to perform high-quality waterproofing, which will ensure durability to any pool.