Foundation and bowl for the pool

Few will refuse to have their own pool. An artificial pond that allows you to relax at any time of the year – if it is closed – or only in the summer, is a great temptation for owners of country houses. However, it is worth noting that the installation of the pool is a rather time-consuming and costly process, in which it is necessary to take into account everything from a competent construction project to what the bowl for the pool will be.

Content

- Foundation laying for the pool

- Types of bowls for artificial ponds

- Concrete tank construction

- Plastic bowls for pools

- Polypropylene pond – cheap, fast

Foundation laying for the pool

After thorough preparation of the pool project, it is possible to implement its device, starting with digging a foundation pit for the foundation of this hydraulic structure. Digging a pit is carried out using an excavator to the required depth. As a rule, this depth is calculated based on the height of the installed pool, plus an additional about 20-30 cm. As for the length and width of the pit, they should exceed the similar parameters of the pool by 50-60 cm. This measure is necessary to install high-quality and effective waterproofing constructions and formwork.

When the stage of digging the pit ends, you can begin to clean its bottom. To do this, manually remove the excess plant roots, smooth the surface of the walls and remove excess soil. Pay particular attention to the condition of the soil into which the foundation for the pool is laid: if it is not loose, and its depth does not exceed 1.5 m, then the strengthening of the walls of the pit can be neglected.

After that, the bottom of the pit is covered with a special bed of sand and gravel. Its thickness is approximately 20-40 cm with average sizes of gravel and sand fractions. The filling is carried out in several layers of 5-10 cm, each of which is densely compacted before laying the next.

Such bedding plays the role of the foundation of the entire hydraulic structure. Then, to level the surface of such a base, a concrete screed is made, the thickness of which varies between 10-15 cm. After that, the foundation for the pool can be considered completed.

At the next stage, preparatory work is carried out to install the bowl of the future pool – the installation of formwork and the installation of the frame from the reinforcement. It is worth noting that today the pool bowls are presented in a fairly wide range. Depending on the material of manufacture and operational characteristics, these bowls require the implementation of certain preparatory work.

Mounting the frame from reinforcement for subsequent concreting

Worth paying attention to! As for the installation of the base for the indoor pool, the scope of work will depend on whether the pool is being constructed at the stage of building a house or being introduced into an existing building. In the first case, even at the stage of designing the house, you can take into account all the features of this hydraulic structure. In the second case, it will be necessary to develop an individual technological scheme, since there is a great risk of digging the supporting part of the apartment building, which can lead to serious deformations.

Types of bowls for artificial ponds

Currently, pool bowls offered to consumers meet the tastes of even the most demanding of them. The choice of one or another bowl, as a rule, is based on many factors, not least of which are its cost, durability and the need for repair. So, the classic option is a bowl of concrete.

Concrete tank construction

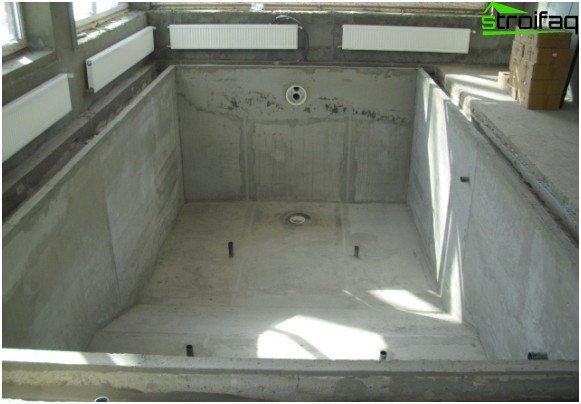

A bowl of a concrete pool is carried out after a number of works, in particular, the installation of fittings and the installation of formwork, which allows you to give the future pool the desired shape. Only after such a frame for the pool is made, the concreting of the bowl is carried out. Concreting is most often carried out in two stages: first, the bottom is poured, and then – the walls.

Concreted Pool Bowl

It is worth noting that the pool bowl made of concrete has many advantages. So, the technology of its manufacture worked out over many years allows to obtain a high-quality and reliable result. In addition, concrete allows pouring formwork of any shape, that is, you can build a pool of any desired configuration. A special role is played by the fact that the construction of a concrete basin bowl can be carried out even with a high level of groundwater. Thus, the concrete bowl of the pool is one of its structural elements, requiring a careful approach to the device.

Plastic bowls for pools

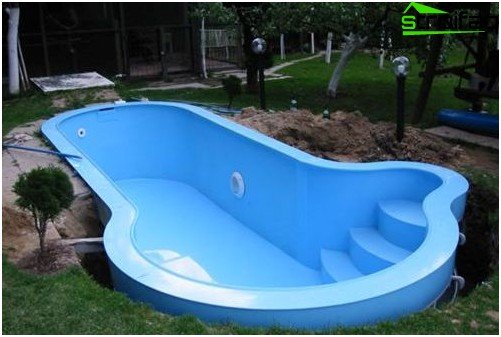

Such bowls in the factory give one form or another. They come to the consumer in finished form, that is, this bowl does not have to be collected. Due to the low weight of the plastic, such bowls are easily transported to the pool.

Plastic basin bowl currently extremely popular, as it is environmentally friendly, safe, easy to install and maintain.

Plastic bowl for the pool

It is worth noting that manufacturers of pool bowls have taken care of satisfying the tastes of a wide range of consumers, as they offer a huge number of products of various shapes. So, plastic bowls for pools can be not only oval or rectangular, but also take quite original outlines.

Polypropylene pond – cheap, fast

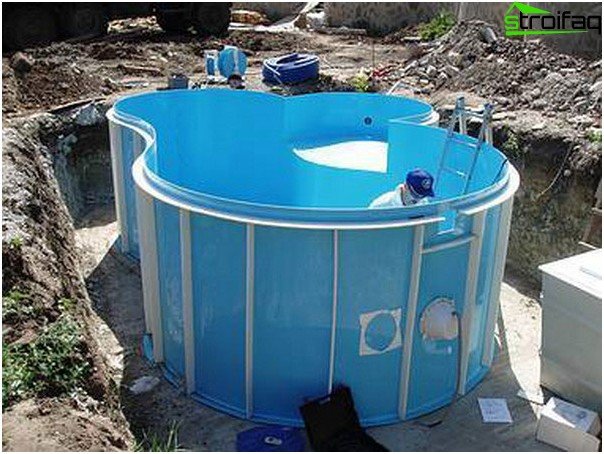

Polypropylene pools are becoming more and more popular every year, due to the combination of quality and rather affordable price, which makes such pools affordable for the population..

A pool bowl is made of polypropylene by welding several sheets of this material.

Polypropylene pool – affordable price plus ease of maintenance

The finished product is characterized by tightness, strength, the ability to avoid additional pool decoration, resistance to temperature fluctuations in water and air, durability and aesthetic appearance.

Frame pools

In some cases, the construction of a capital basin buried in the ground is impossible. This may be due to a variety of reasons, for example, the condition of the soil, lack of funds or a small area of land.

The pool on the frame, it does not need a foundation and foundation pit

In such a situation, you can find a great alternative, which will serve as a frame pool. Outwardly, it looks exactly like one large bowl of the pool, which does not require a foundation pit digging and foundation laying. Such a pool on the frame can be installed anywhere on the land. It can be easily assembled, disassembled and moved from place to place. The small weight of such a pool when assembled allows you to take it to nature or move it to a shady place. The prices for frame pools are quite acceptable, the care is simple, and the operation is comfortable and safe..

Thus, today it is easy to determine the need to equip a pool in a country house, study the technology of their device and select the desired materials for manufacturing.