How to make a pool with your own hands

There are several ways to arrange a pool on the territory of a personal plot. You can purchase an inflatable structure and install it in a few days, but this is a short-lived option. Also, ready-made fiberglass bowls are currently being sold, which are installed in a pre-prepared foundation pit. It is most convenient to build a concrete pool with your own hands, though it will take time. But this construction will last for many years, if during the construction all the requirements of the technology of work are met.

Content

- Concrete Pool Construction

- Factory kit assembly

- Basic equipment of an artificial reservoir

- Operational hand-made installation

- The construction of the pool of polystyrene blocks

- How to make a steel sheet pool

- The device of the reservoir of concrete blocks

Concrete Pool Construction

1. Work begins by identifying a suitable location for the construction of the pool. It is necessary to take into account the depth of groundwater. In areas where their level is located at a distance of 0.5-1 m from the soil surface, it is not recommended to build a stationary concrete pool. It is undesirable to place the structure near the foundations of buildings located on the site.

2. Next, they are determined with the shape and size of the future structure, while proceeding from the fact that the more complex the configuration of the pool and the larger its size, the more financial resources will be required. From this point of view, water bodies having a rectangular shape are the cheapest. It’s easier to build such pools with your own hands, you just need to carefully markup so that all sides of the structure correspond to design calculations.

3. At the next stage, they start digging a pit. To expedite the excavation, it is better to attract special equipment, if, of course, its access to the construction site is possible. If there is a risk of collapse of the walls of the pit, then they are placed under a slight slope to the center. The bottom of the pit should also have a slope in the direction of the drainage pit. This will facilitate further discharge of water during operation of the facility..

Digging a pit for a pool

4. Experts recommend arranging additional drainage of the pit. For this purpose, a small depression is made in the middle, which is covered with gravel. Then the bottom is covered with a sand layer, the thickness of which is from 20 to 30 cm. The sand is carefully compacted. Then a ten-centimeter layer of gravel is poured over the sand, which also needs to be compacted. Do not forget to put all the necessary drain and bulk communications.

5. Next, the bottom is poured with concrete, for the preparation of which cement of a grade of at least 400 is taken. Concrete mortar is poured with a five-centimeter layer. A reinforcing mesh is laid on top, for the manufacture of which a metal wire 6-8 mm thick is used. The mesh cells should have a size of about 15-20 cm. The intersection of the mesh elements are twisted with a soft wire. Another layer of concrete mixture is poured over the mesh, the thickness of which is also 5 cm. As a result, the thickness of the pool bottom will be 10 cm. To ensure uniform drying of concrete, it is moistened with water.

6. After the concrete bottom has hardened, proceed to the construction of formwork for pouring walls. For its manufacture, 30 mm boards are needed. Do not forget to foresee the equipment location in the formwork so that then you do not have to drill concrete, which is completely undesirable. Before pouring the first 15-centimeter layer of concrete, the bottom is wetted with water, this will allow for a denser adhesion of the walls and the bottom. Also for this purpose, aluminum powder is added to the solution prepared for the first layer. Next, a reinforcing mesh prepared in advance is installed in the first concrete layer. Continue to fill the walls in layers. It takes 3-4 days to harden the walls. After the formwork is removed.

Concrete pool formwork

7. The inner part of the concrete walls is plastered and waterproofing works on cold joints.

8. Carry out the installation of removable equipment.

9. Next, proceed to the device of the border, which can be made of brick or pour concrete.

10. Finish the construction of the pool with their own hands by facing, during which the bottom, walls and curb are laid out with tiles. In this case, special adhesive compositions with waterproof properties are used. Tile joints make a little wider than when decorating the walls in the room, filling them with waterproof grout.

11. Next, install the necessary equipment, connect water and enjoy the creation of their own hands..

Factory kit assembly

You can simplify the work if you use special sets of building and assembly systems manufactured by manufacturers equipment for pools.

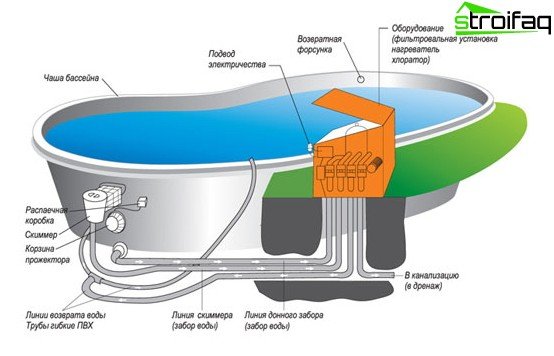

Basic equipment of an artificial reservoir

- wall materials, which are the main elements of the bathing bowl;

- waterproofing;

- facing film;

- fittings;

- embedded parts;

- underwater nozzles;

- flange units;

- skimmer;

- filter;

- pump;

- staircase for descent.

The scheme of the pool

It is possible to supplement the basic kit with piece accessories.

This can be underwater lights, a protective coating, a countercurrent device, a special tool necessary to clean the walls and bottom of the bowl.

Operational hand-made installation

The three basin options discussed below are capital in-depth facilities. At the same time, wall elements that differ in weight, shape and size are easily mounted at the construction site of the artificial reservoir. The cladding film is delivered in a compact roll, and its width is convenient for cutting and installation. In some sets, the film is already “welded” to the size of the bowl and comes in the form of a bag. Before starting work, they are determined with the construction site, the size and shape of the pool, which determines the choice of the most suitable wall material. In his role may be:

- polystyrene blocks;

- steel sheet;

- concrete blocks.

It is advisable to consult with specialists to understand what kind of work can be done with your own hands. Some stages of construction are best left to professionals..

The construction of the pool of polystyrene blocks

This building material is used even in the construction of houses, so it is not at all difficult to make a pool bowl out of it. Large-format blocks, having impressive dimensions in combination with low weight, allow you to lay walls in a short time. Concrete mixture is poured only into the cavities provided for in the design of the blocks. The presence of all fasteners and reinforcing elements, the necessary embedded parts facilitates the installation of the structure. At the same time built do-it-yourself pool Facing looks very impressive, decorating the territory of the garden of a private house. The work is carried out in the following sequence:

1. Paving marking and digging.

2. Pouring the concrete foundation.

3. Installation of blocks with tongue-and-groove fasteners, which simplify the construction of pool walls.

4. Using a conventional hand saw, the blocks are cut to size, and technological holes are cut into them.

5. In the voids available in the blocks, it is necessary to insert reinforcing bars that are necessarily fastened together for subsequent pouring with concrete.

6. Also, before concreting the walls, pipes are inserted into the places designated by the project, while the joint between the pipe and the wall of the structure is filled with sealed self-hardening foam.

7. The “Roman” staircase that provides access to the pool is made of fiberglass reinforced polyester. The design of the stairs is inserted into the prepared recess.

8. Next, the concreting of the walls begins, during which the cavity of the blocks with the pump is filled with ready-mixed concrete.

9. The work is completed by laying the facing film, which is lined with walls and the bottom of the bathing bowl. The pool is filled with water. Decorative plates are laid around its perimeter, emphasizing the edge of the reservoir.

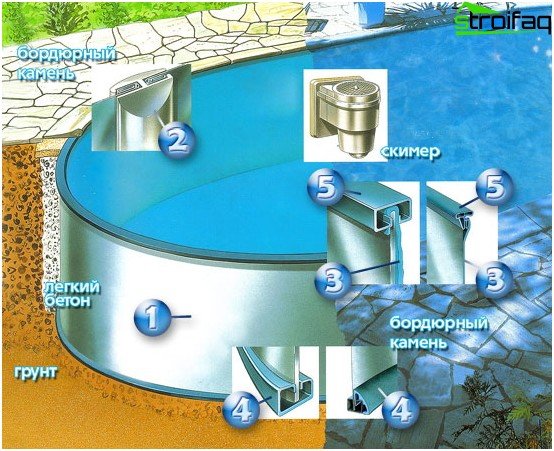

How to make a steel sheet pool

When using this building material for wall mounting, it is possible to carry out the construction of pools with their own hands in a round or oval shape. It is also possible to arrange the bowl in the form of a figure eight. A monolithic concrete slab acts as the base of an artificial reservoir. It is possible to install the structure on well-compacted soil, having previously laid on it a protective non-woven fabric.

Installation of a steel sheet pool

The role of the structural and forming base is played by a wide solid strip of sheet steel, supplied in a roll, which is deployed only before installation directly in the foundation pit at the construction site. A special steel profile is provided for fastening the steel strip to the ring. It is with its help that the installation of a solid and stable bowl design is carried out.

The lining film for the round pool is supplied in the form of a finished large “bag”, which is deployed and fastened around the perimeter of the bathing bowl with an annular mounting profile. The installation of technical equipment is started after the completion of the facing work and the pool is filled with water, which tightly presses the film to the walls and bottom of the structure.

The device of the reservoir of concrete blocks

1. After excavation and the installation of the bottom from a monolithic concrete slab, they begin to install the walls.

2. For the construction of the walls of the pool using standard concrete blocks. In this case, reinforcing every third row of masonry around the perimeter.

3. Instead of an uncomfortable step-ladder, a factory-made staircase descent with convenient wide steps is installed. The design of the stairs is built into the structure during the masonry work.

4. Next, the inner surface of the bowl, laid out of blocks, is lined with insulating material around the entire perimeter.

5. After they carry out the laying of the facing film, which is unwound from the roll, and the individual strips are fastened by cold welding.

6. The upper edge of the film is hidden under a decorative border.

The benefits of a plastic bath

Such swimming pools, bathtubs have recently gained wide distribution due to the fact that their construction is much simpler and faster than the construction of concrete structures. The design of the pool is made in the form of a finished bowl, which is dug into a foundation pit prepared in advance. These finished bathtubs are made from fiberglass, ceramic and composite materials..

Dig a pit according to the size of the workpiece. The bottom is covered with rubble, which is well compacted. Next, the bowl is inserted with the help of lifting devices into the pit. The remaining space between its walls and the walls of the pit is covered with earth. Before buying, you need to clarify the temperature range in which the installation of such a pool is possible. In areas where the soil is very cold, the option of pushing the structure is possible.

Ready-made plastic pool

To advantages plastic pools can include:

- quick construction time;

- Perfect smooth surface that is easy to care for

- built-in ladder in the design of the bowl;

- slower cooling of water in comparison with concrete pools;

- perfect waterproofing;

- long term of operation, reaching up to 50 years;

- the inability to multiply bacteria on the surface of the plastic bowl.

The disadvantages include:

- the high cost of transporting the finished bowl to the installation site;

- installation requires a crane;

- limited choice of models proposed by the manufacturer;

- lack of the ability to order a bowl for a special project.

Problems of construction and operation of pools

1. Ensuring the water resistance of the bathing bowl is the main task that must be solved during the construction of the pool. When assembling prefabricated buildings, this problem is solved with the help of a special film made of hardened polyvinyl chloride. In the construction of concrete pools are sometimes reinsured and also use this material. However, subject to the technology of concreting the walls and the bottom, this is superfluous.

2. Ensuring the purity of water is no less important. To achieve water purity allows properly organized circulation of water, which is cleaned by installed filters. Using a sliding or removable coating, it is possible to protect water from foliage and insects.

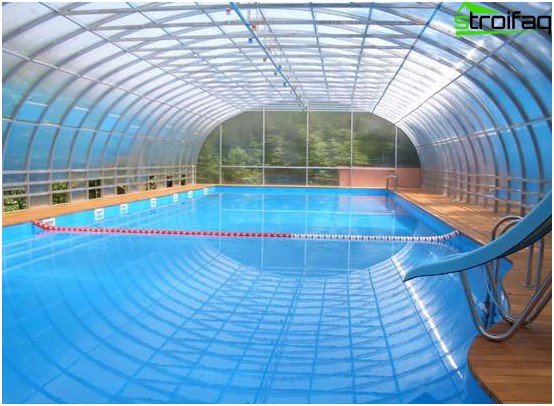

3. The increase in the duration of the season of operation of the pool over three summer months. This is achieved by installing a water heater in the pool. Recently, light canopies over pools have been arranged, allowing them to be used for six months..

Construction of swimming pools under a canopy

If you want year-round operation of the pool, its construction must be carried out indoors, while using building materials suitable for rooms with high humidity. Forced dehumidification using special equipment is required. The requirements for the ventilation system of such a room are also high..

Photo selection of individual pools

Pool for a summer residence

Pool shape selection

Pool size selection

Above, several options for how to make a pool with your own hands are considered. After reading the article, you need to calculate the costs of each method and the possibility of its application in the region of your residence. Choosing the most economical option, you can proceed with the construction of an artificial reservoir, which will bring a lot of joy to all family members and guests. Now the summer hot days will not be scary, because the cool water of the constructed pool will save from heat. Now, to swim, you do not need to go to a nearby lake or river, because next to the house is its own pond, built by own hands.