Polypropylene Pools

Nowadays, the pool in the country is not uncommon and exotic. This pattern is justified, because time spent in the pool positively affects the tone of the body, a person relaxes and restores his strength. The rhythm of modern life is too dynamic, so good relaxation is essential for people. An artificial reservoir in the country is the right decision, all the more, it can be purchased in the form of a finished bowl, and then installed on the site on your own. Pools made of polypropylene – an excellent option, it is a quality and quick solution. In addition, they are very popular due to the fast manufacturing technology..

Content

- Numerous pros for polypropylene

- Polypropylene Bowl Production

- Extensive scope

- Polypropylene pool mounting algorithm

- Operation and Maintenance Tips

Numerous pros for polypropylene

The pool made of polypropylene deserves increased attention and justified praise, since this material has many quality indicators. I would like to note the main advantages in order to get to know this material more closely:

– polypropylene is characterized by low vapor, heat and gas permeability. At the construction stage, heat-insulating materials do not need to be used for pool equipment, since low thermal conductivity helps to maintain a stable temperature in the bowl. The result is energy savings (water is heated, not ground and concrete screed);

Various configurations

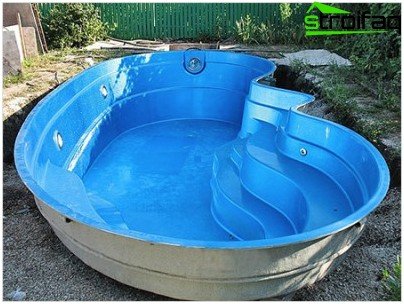

– the ability to create pools of various configurations;

– clean water for a long time;

– safety – when wetted, the pool surface does not become slippery;

– high mechanical and impact strength, as well as excellent resistance to repeated bending. Polypropylene is not afraid of seasonal climate changes and pools made of this material can be installed outdoors;

– resistance to aggressive environments: acids, alkalis, ultraviolet rays. Polypropylene does not enter into chemical reactions, therefore, when choosing a means for chemical cleaning and disinfection, you can not be afraid of the consequences of their use, the pool will not lose its appearance;

– ease of care, polypropylene does not lose its original brightness and color, does not fade and is easy to clean;

– polypropylene bowl does not need additional decoration and lining. The finished design does not require facing with tiles or film, since the inner surface has a finished look;

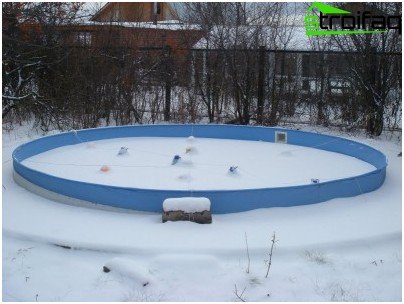

– resistance to high and low temperatures. A great advantage – in winter, you can not drain the water, but use the outdoor pool as a skating rink;

For the winter, the pool of polypropylene does not need to be dismantled, there is no need to drain water from an artificial reservoir

– 100% tightness of the bowl and additional equipment (nozzles, drains, overflows, searchlights);

– reasonable price-quality ratio – affordable cost, excellent quality;

– short terms of installation;

Ready-made polypropylene bowl facilitates and speeds up the process of building your own pool

– significant savings in construction (no costs for waterproofing, leveling the surface, cladding);

– durability (up to 20 years) and environmental safety.

Polypropylene Bowl Production

The technology for manufacturing pools of polypropylene is to use sheet polypropylene, which is being welded. Moreover, for different parts of the structure, that is, for walls, bottom, etc. different material thicknesses are used.

Sheets are practically welded “butt” and the joints are almost imperceptible. And the indicator of the strength of the seams is so high that it can be confidently stated that there is no difference between the integral section and the welded one. Due to the high degree of structural strength, the manufacture of pools made of polypropylene is actively popularized, because more and more consumers are interested in them..

Extensive scope

The range of applications of polypropylene is wide enough (still, with such quality characteristics), from it are made:

- private pools in cottages;

- children’s pools (in rest homes, sanatoriums, kindergartens);

- outdoor pools;

- bathtubs, jacuzzi, fonts;

- community pools;

- various containers and tanks.

Polypropylene pool mounting algorithm

Surely everyone watched foreign films and admired the chic pools, secretly dreaming of such a “miracle” on their territory. Previously, full, beautiful and multifunctional pools were the prerogative of rich people. But today the situation has changed dramatically for ordinary people who do not have impressive bank accounts. Now the construction of pools is quick, not too laborious and affordable.

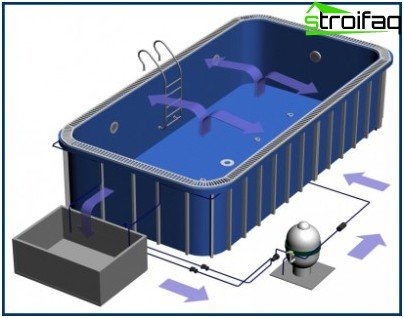

The device of the pool water supply made of polypropylene, as well as the scheme of circulation, purification and heating of water

Well, for even greater savings, many people are interested in the question of how to make a pool out of polypropylene without resorting to the help of a hired brigade of workers. To do this, you need to know the installation process of these pools, which consists of the following stages:

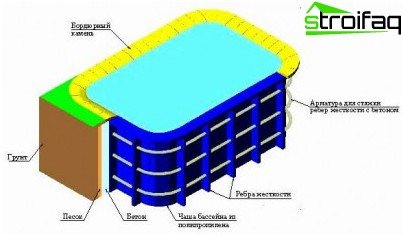

– under the polypropylene pool, you must first dig a pit – it should be slightly larger in size than the bowl itself. In the case of groundwater lying close to the surface, drainage is done to protect the bowl from hydrostatic pressure;

– laying on the bottom of the pit litter of sand, gravel, crushed stone (thickness 50 cm). On such a sandy bedding a small concrete base is equipped. A plate with reinforcement is poured with concrete mixture, and after drying it is ground to eliminate roughness and roughness. The surface of the concrete slab should not have any irregularities;

Polypropylene pool embedding scheme

– the next stage – the finished bowl is mounted in a prepared foundation pit on a concrete slab;

Important: if the pool of polypropylene is in the room, the final assembly of the structure takes place on the spot.

– installation of all kinds of embedded elements – skimmers, bottom drains, lighting equipment, a pipe system around the perimeter. If all the parts are already in place, then you can proceed to concreting the walls of the pool. One side for a concrete tape is a polypropylene bowl, the other – the walls of the pit;

– the final stage is the establishment of equipment and the beginning of the functioning of the pool. At all stages, if we consider the work from the moment of ordering the bowl until the first immersion in a new artificial pond, it takes about 2-4 weeks.

Construction of the pool on their own: a plastic bowl is installed in the pit

Operation and Maintenance Tips

Since in the country you can equip pools of polypropylene with your own hands of various sizes and non-standard shapes, they can ideally fit into the design of any summer cottage. In addition, the material can be of different colors, despite the fact that the most common blue color.

Water in such pools can not be drained all year round for five years. Water in the filtration system passes through a sand filter, this ensures its purity for a long time.

Pool made of polypropylene in the country: cheap, fast, reliable

Pool Service does not take much time. Algae can be controlled using cleaning agents. And the surface of the pool should be periodically cleaned with a special brush, which is designed specifically for this purpose. Such a brush is attached to the telescopic tube and connected with a hose to a skimmer.

A large selection of additional equipment, which includes various automation, filtration devices, as well as a wide range of underwater lighting equipment, electric heaters and hydromassages makes the stay in the pool even more enjoyable. Modern technologies do not stand still, it is necessary to use them and change your life for the better. A self-made polypropylene pool is a big benefit, and the pleasure of relaxing is even greater!