Plastic pools

Fans of country life every year becomes more and more. It is understandable: fresh air, friendly gatherings, barbecue on charcoal and, of course, relaxation by your own pond. A dream, and more! And if earlier the last point caused significant difficulties in the implementation, because the pool on the infield was considered not only troublesome, but also costly, today plastic pools easily refute this statement.

Content

- Advantages and types of plastic pools

- About the pros of plastic

- Polypropylene capacity: the secret to success

- Varieties of plastic pools

Advantages and types of plastic pools

Ready-made plastic bowl – installation speed, ease of maintenance, operation without problems

Plastic pools are recognized leaders in popularity. This is explained by the features of the material, which helped them to take first place on the podium..

About the pros of plastic

What explains such excitement around plastic tanks? Let’s get it together.

- resistance to ultraviolet radiation. Pools for summer cottages plastic ones do not fade, which is especially valuable when installed in an open area;

- seamless design. The absence of seams significantly increases the level of reliability: such a pool will definitely not flow;

- high resistance to chemical influences and durability;

- simple installation, quick commissioning;

- resistance to temperature fluctuations;

- reasonable cost. Perhaps this item will please many, because it provides an opportunity for a little money to create a paradise with a crystal clear lake.

Polypropylene capacity: the secret to success

It is worth noting that, despite the abundance of plastic materials, polypropylene is recognized as the best. And all because he, in addition to the above advantages, has exceptional qualities.

Polypropylene – an environmentally friendly material that does not emit harmful substances into the water and does not come into contact with cleaning agents.

It is important! Polypropylene is recommended by the State Department of Sanitary and Epidemiological Surveillance as the best material for the manufacture of swimming pools for children. Worried about the health of your beloved child? Polypropylene plastic pool for children – this is the choice of caring parents.

High manufacturability of polypropylene allows the manufacture of tanks of any depth and shape. You can choose either a standard rectangular or cylindrical shape, or order any other – there are no barriers to imagination. The color schemes are also diverse: to convince you that no one will be blue in the pool!

Polypropylene takes any form

The polypropylene bowl has a low thermal conductivity, which means that it can maintain the stability of the temperature regime for a long time. This quality will save on the use of water heaters and insulation materials an impressive amount.

When building a pool of polypropylene, there is no need for additional finishing. The surface is just perfect: it is easy to clean, looks beautiful and does not slip at all.

The advantages can be enumerated endlessly, but, perhaps, the above arguments are quite enough to prefer a plastic pool to any other.

Varieties of plastic pools

Today, there are 2 types of plastic tanks: monolithic and prefabricated, the second, in turn, are divided into composite and frame.

They differ in bowls: in monolithic designs, an integral bowl is used, and plastic prefabricated pools consist of several elements.

Frame assemblies are assembled by mechanical articulation, and the elements of composite pools are welded together.

You need to know! Prefabricated pools have slightly worse aesthetic characteristics, so they are not so in demand compared to monolithic plastic pools.

Monolithic pools are made of polypropylene sheet, a width of 6-15 mm. Thermal welding allows you to give them any shape and any size.

We install a plastic pool with our own hands

Another advantage of plastic pools is that the installation does not require specialized knowledge. A little patience and useful information, and the pool will serve as a central element of landscape decoration and a place for kids’s favorite games..

First you need to determine the location of the reservoir. On the question of choice which is not everyone thinks, but in vain.

Expert advice! Place the plastic pool on a flat horizontal surface, in the complete absence of gravel, sand, asphalt or roofing felts. If possible, keep the pool away from trees, as crowns will clog the water, and the roots can damage the base.

The numbers you need to know

In order for the pool to give exclusively positive emotions, and not turn into a source of problems, it is worth considering some points. One of the main conditions – groundwater should be 20 cm below the bottom plate (at least).

Starting to dig a pit, make sure that its size is 15 cm larger than the pool bowl. The depth of the pit is calculated from the depth and the fit of the layer. The thickness is determined by the composition of the soil and is equal to:

– for gravel and sandy soils – 200 mm;

– for sandy and loamy soils – 250 mm.

If you decide to install the pool directly on the ground, then the depth will accordingly be 0.

The sequence of work on the device of the reservoir

With the prevalence of sandy and loamy soils, characterized by weak bearing capacity, strengthening is required. You can use one of the options:

1. Tamping soil.

2. Arrangement of a soil pillow.

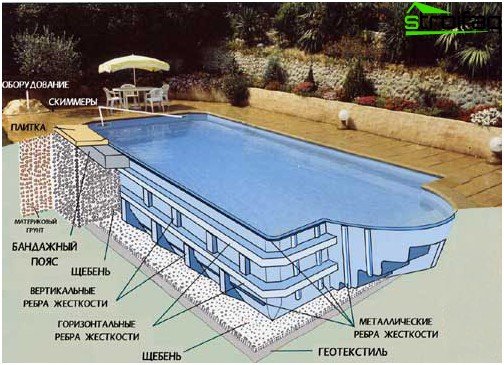

Plastic pool: device diagram

The second option is preferable. A pillow consisting of concrete and sand (sometimes crushed stone and sand) is laid at the bottom of the pit. The optimum thickness is 50 mm. The mortar for cement and sand screed should be kneaded according to the proportions: 3 parts sand, 1 part cement and 0.5 water.

After drying the pillow (about 3 days later), formwork can be installed.

The bottom is reinforced along the entire contour, with a height of 200 mm.

It is important! For reinforcement, steel wire 12 mm thick is used, which must be connected into 25 cm cells.

Crushed stone pillow and concrete screed – a solid foundation for the constructed pool, protection for the bottom of the structure

For leveling (after a couple of days), a cement-sand screed with a layer of 20 mm is applied to the bottom surface. Then polystyrene with a thickness of 40-50 mm is laid on the finished concrete slab, installed on top pool bowl. It must be filled with water gradually. When filling, carefully monitor the fluid level. At a time, you can fill no more than 30 cm.

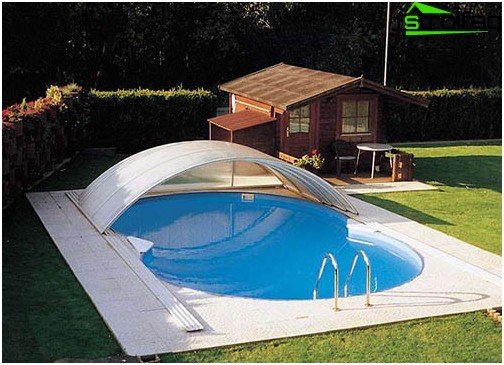

Plastic pool for a summer residence: the result of work

The intervals between the bowl and the side formwork are covered with cement and sand, poured with water and rammed. The final stage – filling the pits that formed between the ground and the formwork.

Expert advice! There are often cases when, in an effort to save money, the townsfolk are limited only to the installation of a sand cushion and foam formwork. However, ignoring the above sequence and the lack of a cement frame leads to cracks.

The work is completed, which means that soon it will be possible to move on to the most pleasant thing – testing a brand new pool, which, subject to the technology, will be held with a bang. Cheerful laughter of children and happy faces of relatives will serve as the best confirmation of this and the most coveted reward for your labors.