Effective foundation waterproofing

The construction of a reliable and strong house directly depends on how well the foundation is laid. To make it durable is possible only subject to certain rules and norms at all stages of creation. In particular, one of them is the waterproofing of the foundation. Today, the market can offer a large selection of different materials. When waterproofing the foundation, materials are selected according to the environmental conditions in which the foundation will be operated, and their own financial capabilities.

Content

- Coating waterproofing materials

- Roll waterproofing for foundations

- Structural treatment with penetrating insulating compounds

For the foundation, there are two types of hydro-threats. These are surface water (rain, snow, etc.) and groundwater (groundwater). To protect against surface water, a blind area is created, but to protect against groundwater, various waterproofing materials have to be used. Sometimes during construction they can do without waterproofing, but such a decision will be erroneous for a number of reasons:

- Even when the groundwater level will be at a depth of 1 m or more from the base of the foundation, during spring flood, the groundwater level will rise 1-2 meters or higher, which will pose a threat to the foundation.

- The level of groundwater tends to change its depth not only seasonally, but also over the years. Various factors contribute to this, from compaction of soils and building density to the arrangement of drainage and water bodies..

- When building a house on waterproof soil with water-permeable layers, it is necessary to make high-quality waterproofing. The thing is that on such soils the water does not go down, but moves towards the foundation. Waterproof soils include clay, sandy loam and loam.

It is important to know that when the groundwater level is higher than the foundation, you can’t do without creating drainage. It will slightly lower the water level and thereby reduce the pressure on the foundation.

There are several ways to waterproof the foundation.

Coating waterproofing materials

This method is one of the easiest and cheapest. Most often, bitumen mastic is used for waterproofing the foundation and mastic based on synthetic (rubber) resins, as well as any cement-based waterproofing materials.

Coating waterproofing can be applied using a roller, brush or spatula. It all depends on the type of waterproofing materials.

Bitumen foundation waterproofing

You can make such a waterproofing as follows:

– We clear the surface of everything that interferes with high-quality adhesion.

– We put the first layer of waterproofing and let dry.

– Now you can apply the base coat.

Mastics have their pros and cons. The advantages are ease of use and low cost. Of the minuses, it should be noted low ductility and mechanical strength, a rather long time of complete drying and damage by plant roots.

Roll waterproofing for foundations

The second name of this method is the gluing waterproofing of the foundation, it is carried out by the joint efforts of several people. To perform this type of waterproofing, traditional materials such as roofing, ruberoid, glassine, as well as hydroisol, glassisol, hydrostekloizol, glasselast, rubitex, proficrom are used. Rolled waterproofing can be divided into non-adhesive and self-adhesive. For the first option, you will need a powerful gas burner or applying hot bitumen, on which roll waterproofing will be laid. Typically, the first method is used when waterproofing the foundation with roofing material or roofing felt..

Rolled waterproofing of the foundation

You can make such a waterproofing as follows:

– We clear the surface of everything that interferes with high-quality adhesion.

– For non-adhesive roll waterproofing, we apply a layer of hot bitumen mastic and we already glue a canvas of roofing felt or roofing felts on it. For high-quality waterproofing, a minimum of 2 layers of fabric should be applied. This is a job for two or three people. One warms up the base with a lamp, and the other two lay the roll.

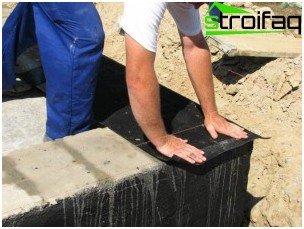

– Self-adhesive roll waterproofing can be applied directly to the surface. The principle of pasting is the same as for wallpaper. A distinctive feature of this kind of materials is the high rate of waterproofing.

Self-adhesive foundation waterproofing

It is important to know that when gluing with a roll type of waterproofing, overlap sheets should be laid, one on top of the other. This way more reliable water protection is achieved..

The advantages of this type of waterproofing are its high durability, tear resistance and high elongation. Of the minuses – the high cost of materials.

Structural treatment with penetrating insulating compounds

This method is used mainly for internal work and for repairing foundation joints. This type of waterproofing is made on the basis of cement with the addition of specially ground sand and chemically active substances..

You can make such a waterproofing as follows:

– We clear the surface of everything that interferes with high-quality adhesion.

– We put a layer of waterproofing with a spatula and allow to dry..

Penetrating waterproofing foundation

The principle of operation of this type of waterproofing is that when water enters, the sealing process begins, and the concrete is self-healing. The main disadvantage is very little ductility, which, when the foundation is deformed and vibrated, leads to the destruction of the integrity of the protective layer.

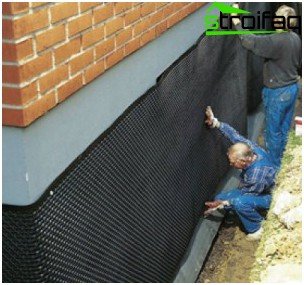

After laying the main layer of waterproofing, you can further strengthen the foundation with polymer membranes, drainage and thermal insulation.

The whole range of waterproofing materials is widely represented in the Technonikol company. Due to the integrated use of Technonikol materials, waterproofing the foundation will gain better protection, which will increase the life of the foundation and provide coziness and comfort in the house.