Which cork floor is better to choose

Cork is one of the youngest flooring. It still causes a certain resonance among the consumer. Someone, hoarse, is ready to prove that cork floors are just perfect, but there are those who are dissatisfied with the results of their use. Let’s try to understand objectively whether the cork is good for flooring, and how to choose this material. After all, most of the information is provided by construction stores, most of which are simply trying to sell goods.

Content

- What is cork floors

- The main qualities of cork

- How to choose a cork floor

What is cork floors

A cork is nothing but the old bark of some varieties of wood, which is carefully removed from the trunk every 9-15 years, after which it begins to grow again. Moreover, with each removal, the quality of the material only improves.

In its composition, a cork is a multitude of the smallest chambers, sealed and filled with nitrogen and oxygen, which makes it light, flexible and resilient. It retains its shape almost completely even after exposure to heavy loads..

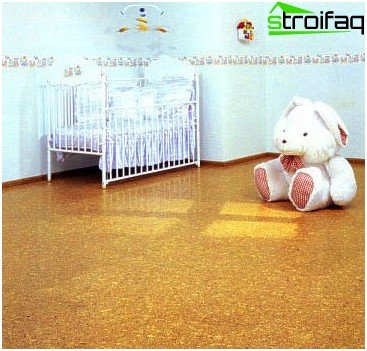

Cork floors – ideal for children – warm, comfortable

The main qualities of cork

Why is cork flooring better than everyone else? Consider the main advantages and disadvantages of the material.

- The first thing sellers focus on is the absolute environmental friendliness of the material. This is true, but only if the coating is purchased in the form of solid veneer balsa wood. If the floor tile is made of agglomerate, then the level of environmental friendliness is significantly reduced, because in order to glue cork particles together (and agglomerate is cork chips), it is necessary to use various adhesives and plasticizers obtained in the chemical industry.

- Low thermal conductivity. Yes, cork coating has a thermal conductivity coefficient that is only slightly higher than the corresponding indicator for air (cork – 0.04, air – 0.02). This allows you not to use a special heat insulator when laying flooring. In addition, the floors of cork reviews of people already using them determine how very pleasant and warm to the touch. This is because cork does not cool human skin as quickly as, for example, tiles or concrete.

- Low sound conductivity. The cork absorbs sound remarkably, but only if its thickness exceeds 3 mm. Therefore, if you are a lover of loud music or noisy parties, replacing the flooring with a cork 10-15 mm high will help keep the peace with neighbors.

- The cork is resistant to mechanical and chemical damage. In fact, this statement is not entirely true. The residual deformation of the cork is 0.2 mm, that is, after strong physical exertion, it still may not completely restore its surface. In addition, the coating is very afraid of sharp objects, heels, claws of pets, that is, anything that can pierce or tear. If we talk about chemicals, then cork floors are practically not exposed to acids, but it must be protected from alkalis.

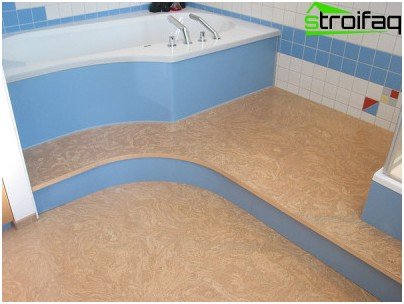

- Another “favorite callus” that all sellers like to press on is moisture resistance. Again, only cork veneer floors have absolute water immunity. In other cases, the cork is glued onto a panel of MDF or HDF, which under the action of water significantly deforms, so the use of such a coating in bathrooms and other rooms with high humidity is unacceptable.

- Another controversial feature of cork is its roughness. Some complain that socks and tights are wiped very quickly, the same applies to floor rags, as well as the difficulty of cleaning, while others do not like the excessive slippery of the cork. It all depends on the composition with which the material is coated, so when you buy it you need to pay due attention.

The surface roughness of the cork floor depends on the coating composition

How to choose a cork floor

Cork flooring – how to choose the best option? This question interests almost everyone who is interested in this flooring..

Of course, first of all, you should pay attention to the manufacturer. Portugal is considered the main producer of cork, Spain, China and Poland are slightly behind. The material produced in these countries is of the highest quality..

Next, be sure to look at the packaging. Cork slices should be made correctly, with no nicks or burrs. The wrong side of a good coating is dense and uniform. You should also compare the plates from different boxes. Their cuts must be the same, otherwise gaps will form during installation.

For the bathroom and kitchen, you should buy a cork coating from a single sheet, only it has the necessary water-repellent properties for these rooms. For the rest of the rooms you can buy floating cork floors. These are cork sheets glued to an MDF or HDF board and fastened together with special locks. This coating can be disassembled and reassembled..

Option for laying cork floors in the bathroom: using a whole sheet

Foreign materials visible on the slice of the slab are not allowed. Many manufacturers fill panels with sawdust or industrial waste to save costly cork. Extraneous inclusions significantly reduce all expected coating qualities.

We hope that our article will help you decide on the choice of cork flooring, and you will enjoy this cozy and comfortable flooring for many years..