How to glue linoleum

One of the advantages of linoleum, due to which this finishing material is popularly popular, is the ease of installation. After all, really correctly laid on any, but always well-prepared, even base, linoleum can serve for decades. True, discussions often arise on whether glue for linoleum is an excess, if this flooring can be laid on the base with a single panel, fixing the edges with skirting boards.

Content

- Why do I need to glue linoleum

- Dispersion adhesives for linoleum

- Reaction adhesives for linoleum

- A-type cold welding

- C-type cold welding

- T-type cold welding

Why do I need to glue linoleum

Not so long ago, if it was not possible to “get” linoleum of the required width, they bought what was and glued the canvas to the base with PVA glue or Bustilat. Today, when it is possible to choose a floor covering both in design, in terms of durability, and in width, the temptation is too great to buy a linoleum roll of optimal width and length, lay it in a couple of hours and enjoy the updated floor. At the same time, manufacturers insistently recommend laying linoleum on the glue, and, depending on the type and basis of the coating, select one or another adhesive composition.

The use of glue when laying linoleum allows you to create a solid monolithic flooring and neat barely noticeable seams at the joints of paintings

Using glue allows you to create a solid monolithic floor covering, rigidly strengthened at every point of the base of the floor. During operation, the width of the joint between the webs will not change, that is, the seam will never go apart. On the surface of a rigidly glued elastic floor covering, no swelling from the legs of the chairs appears, and when the furniture is moved, there is no wave characteristic of freely laid linoleum. Finally, the floor will last you 40-50% longer, preserving a beautiful appearance if laid on linoleum adhesive: its price, by the way, is ten times lower than the cost of the flooring itself.

Thus, through the use of special adhesives, a strong connection of the linoleum base with the floor is provided, and a strong seam is created at the junction of the two coating strips. Deciding what glue to stick linoleum with is necessary depending on the type of coating base and the laying stage. There are three types of adhesives for laying linoleum:

- dispersive;

- reactionary;

- universal.

Dispersion adhesives for linoleum

Dispersion glue is a water suspension and solutions of acrylic or carboxymethyl cellulose with the addition of chalk, latex and other special additives. This group of adhesives is almost odorless, nontoxic, they are also not water resistant and lose their adhesive ability in case of freezing during transportation. Dispersion glue can be used when laying linoleum on different bases: fabric, felt, made of foamed polyurethane. The most common types of dispersion glue:

- Acrylate – suitable for laying heterogeneous and homogeneous linoleums in rooms with moderate to high cross.

- Bustilate is an adhesive based on carboxymethyl cellulose, latex and chalk, ideal for gluing insulated felt linoleums.

- Gumilaks – adhesive based on latex and rubber, used when laying natural linoleum.

- Conductive dispersion adhesive is used in conjunction with antistatic flooring when laying in rooms with a large number of electronic equipment.

- Dispersion and bitumen mastics for laying linoleum on a fabric basis.

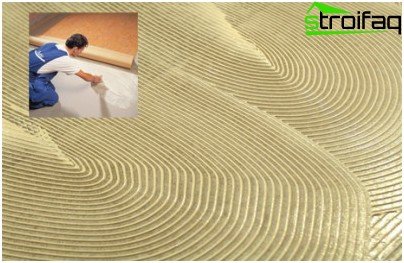

All types of dispersion adhesives and mastics are applied to the floor with a notched trowel evenly.

All types of dispersion adhesives and mastics are applied to the floor with a notched trowel in an even layer of 0.6-0.7 mm thick and linoleum is laid immediately. The consumption of glue for linoleum, depending on its type, is 200-500 g / m 2. Floor coatings on mastics and adhesives based on bitumen are laid in 15-20 minutes after applying the composition to the floor.

Reaction adhesives for linoleum

Reaction glue is a complex chemical compound based on polyurethane and epoxy. Entering into reaction with the base of linoleum, it firmly glues it to the floor surface, providing a very hard intermediate layer, waterproof, durable, resistant to mechanical stress. Reaction glue is good for laying linoleum on a fabric basis and is indispensable for laying commercial linoleum in industrial premises. It has the highest gluing ability, but is not free from disadvantages, among which are noted

- high cost in comparison with dispersion adhesives;

- pungent odor;

- explosion hazard;

- fire hazard.

Laying linoleum with a reaction glue is called cold welding due to the chemical reaction taking place, and depending on the concentration of the adhesive, three types are distinguished – A, C and T. Depending on the type of linoleum, the age of the floor and the nature of the upcoming operation, select the appropriate glue for cold welding of linoleum of one type or another.

A-type cold welding

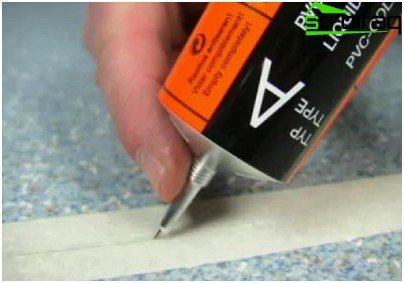

The reaction adhesive of the most liquid consistency is suitable for gluing strips of commercial or solid household new linoleum at the joints, provided that the pieces of material are already tightly laid on the adhesive and the pattern is well aligned. The result is a thin, almost invisible transparent seam that can only be detected by touch..

The use of A-type cold welding allows you to get an almost invisible transparent seam that can only be detected by touch..

C-type cold welding

The reaction glue is of a rather thick consistency, intended for the repair of the new linoleum. As a rule, during the operation of freely laid linoleum, cracks from 0.3-0.5 to 3-4 mm wide can form at the joints, which a thick adhesive not only glues the edges of the material, but also practically creates a strip of new linoleum in place of the gap.

Thus, C-type cold welding is used to produce wide, thick joints..

T-type cold welding

This type of composition for cold welding is used by professionals as an adhesive for joints of linoleum from PVC based on polyester.

Hot welding linoleum

When laying dense commercial linoleum or when performing applications and other artistic design techniques, it is not always possible to create a neat waterproof layer between parts using glue and then use the hot welding method.

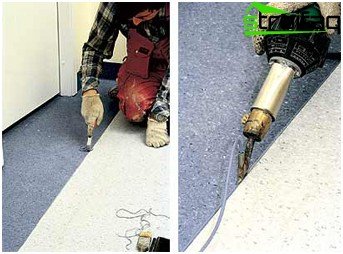

Bonding linoleum strips using hot welding

The operation of hot welding is performed only by professionals with the help of a building hair dryer with a special nozzle, in which a welding cord that fits a particular type of linoleum is laid. Cloths of material are tightly adjusted to each other, and a welding cord is laid in a narrow slot between them. Under the influence of high temperature of 300-400 ° C, the cord melts and connects the linoleum parts with an even strong seam.

For welding pieces of soft household linoleum, hot welding is not used, to create invisible thin seams in this case, cold welding is enough. Despite aggressive chemical activity, subject to the necessary safety standards, the cold welding method is simple to implement, provides an amazing result when laying flooring and opens the good old linoleum in our homes from a new unexpected side.