Concrete floor repair

For many years, experts have noted that concrete floors have won the love of consumers and have become widespread. This position of concrete floors is determined by their operational properties and excellent characteristics. So, they are distinguished not only by a high degree of strength, but also by a low dust removal rate and resistance to chemical influences and deformations. In addition, the cost of concrete floors is low, which is also their undoubted advantage. Despite the many advantages, sooner or later repair of concrete floors is inevitable.

Content

- Need for concrete floor repair

- Causes of floor defects

- Destructive action of soil

- Various internal factors

- The impact of external negativity

Need for concrete floor repair

Obviously, no matter how durable the floor is, it is constantly exposed to a wide variety of influences: mechanical or chemical. This leads to the occurrence of defects of one complexity or another on the coating surface. However, modern technologies and materials can successfully eliminate most of the damage and restore the original aesthetic appearance of the concrete floor.

It is obvious that timely and high-quality repair of the concrete floor will increase its service life and save you from unwanted money and time costs for laying a new floor.

Concrete floor restoration: crack repair

Before proceeding with restoration work, it is necessary to conduct a thorough diagnosis of the damage and determine the cause of their occurrence as accurately as possible. This will allow you to choose the right technology for eliminating defects..

Causes of floor defects

Today, all the causes of various defects of the concrete floor can be combined into several groups.

Destructive action of soil

The main problems experts include swelling of the soil in the winter in poorly heated rooms; poor compaction of bulk soil; shrinkage of the structure that has occurred over time; groundwater washing and many other problems.

In such situations, the front concrete coating can look quite attractive and meet the existing operating conditions, however, if internal defects are detected, a major reconstruction is necessary.

Various internal factors

They usually include the formation of cracks as a result of shrinkage or insufficient care of the floor surface in the first hours after installation; peeling of a concrete layer from a surface. In the event of such situations, the surface of the concrete floor is subject to restoration work only after carrying out the complex repair necessary in a particular case.

The impact of external negativity

An external factor affecting the state of the concrete floor and leading to its destruction can be considered dusting of concrete as a result of natural wear of the coating surface; potholes and chips from exposure to the floor with heavy objects; chemical corrosion.

If the damage is local in nature, and does not affect the entire surface of the floor, then measures are taken to eliminate existing defects and strengthen the floor with special compounds.

Otherwise, when the damage is widespread, the elimination of defects will not be enough. Experts recommend resorting to the removal of the old concrete pavement and the installation of a new floor.

Today, it is customary to subdivide all defects of a concrete floor into several groups depending on their complexity. The most common problem of this gender is considered to be the appearance of cracks.

Crack repair in concrete floor

Undoubtedly, cracks on the surface of a concrete floor can be various, both small, and larger and deeper. Repair of deep cracks is more complex, requires more time and financial costs..

Small crack repair

Such repair of cracks in the concrete floor does not take much time, does not require the use of massive and complex equipment, taking, respectively, less time.

So, the elimination of a crack must begin with a thorough examination. It will help to identify the presence of chips near it, ignoring which can lead to negative consequences, in particular, the appearance of pits in the floor surface.

To prevent the occurrence of such a situation, it is necessary to use a chisel and walk along the crack, tapping the tool with a hammer. This measure will help to detect hidden chips, which can subsequently be eliminated..

Using the same chisel, a crack in the surface of a concrete floor is shaped like a regular cone. Then dust and all debris are removed from it, and the crack itself is poured with water.

The expansion of the crack with a chisel will help to identify and eliminate all weak areas before repair

This was the preparatory phase for repairing a crack in the concrete floor. After its completion, a cement mixture should be prepared in which PVA glue is added. The result should be a fairly fluid composition that is poured into the crack.

When pouring the mixture, it should be remembered that it shrinks. That is why you should fill the solution just above the floor level. Surplus can be removed with a spatula or regular wooden plank..

After the cement mortar has dried, the floor surface is treated with a grinding machine, and in its absence, with an abrasive wheel. To eliminate concrete dust, the floor surface is locally poured with water.

Deep crack repair

If quite deep and large cracks are found in the concrete floor, then using the means at hand will no longer work..

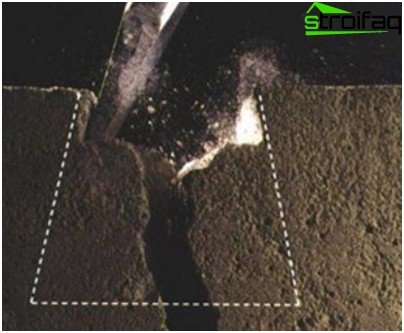

So, to begin work, it is necessary to make special cuts along the existing cracks using a circular saw. They are necessary in order to completely eliminate part of the concrete floor that has undergone deformation..

It is worth paying attention to the fact that when working with a circular saw, a diamond blade is used.

Using a chisel and a hammer, all concrete should be removed from the cut. The resulting “flap” is cleaned of dust, that is, filled with water. In addition, this will improve the adhesion of mortar and concrete.

As in the case of small cracks, a previously prepared cement mortar is poured into the crack a little higher than the floor level. After that, the surface of the floor must be grouted using a grinder.

Filling the treated crack with a repair compound

After removing excess mortar, you can enjoy the look of a flat concrete floor.

How to repair shrinkage cracks

In the event of shrinkage cracks with the help of a special machine, they are “embroidered” with a depth of up to 5 mm. Then the concrete dust is eliminated, the crack is primed and filled with a repair compound.

The repair compound used must not shrink!

After carrying out repair work and complete hardening of the composition poured into the crack, the floor surface is ground.

To prevent the occurrence of shrinkage cracks, experts recommend the use of special mineral-polymer complexes, which are added to the concrete at the stage of its mixing. These compounds compact the structure of concrete and compensate for its shrinkage..

Other types of concrete floor defects

Today, in addition to traditional cracks, there are a fairly large number of other defects of the concrete floor that must be eliminated. Their complexity determines the need to use certain equipment and technologies for the restoration of concrete floors.

Local delamination on the front surface

If local delaminations from the underlying base occur on the surface of the concrete floor, you can use special compounds.

As a rule, these are solutions based on epoxy resins, characterized by a low degree of viscosity, are introduced under the front coating by injection.

With large-scale exfoliation, reinforcement of the concrete floor by injection is no longer possible, it is necessary to remove the destroyed top layer and fill in a new screed

With the massive nature of delaminations, it is recommended to completely remove the existing coating and lay the new concrete floor. However, all work must be done only after careful preparation of the underlying foundation..

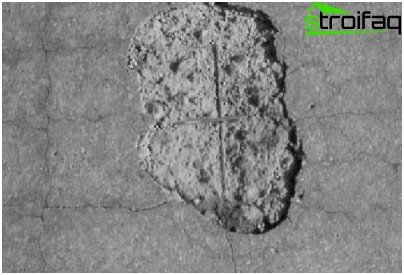

Concrete floor potholes

Quite often, potholes occur on the surface of the concrete floor. Most often, their appearance is associated with the fall on the floor of heavy objects.

Potholes on the surface of the concrete floor are poured with cement

Existing potholes must be thoroughly cleaned of debris, dust and oils, if any. Then a priming is carried out, which improves the adhesion of concrete and repair composition. As a rule, prepared potholes are poured with a cement composition with the addition of reinforcing agents.

Particular attention is recommended to be paid to the conditions in which the repair compound must harden. So, the areas of the concrete floor that underwent repair must be kept under the film in conditions of high humidity. In addition, for 8-10 days, the floor surface must be protected from any loads..

Elimination of horizontal bumps

Horizontal irregularities are the result of poor-quality concrete floor casting and violation of appropriate technologies. To eliminate these irregularities, a special machine is used, with which the base of the concrete floor is milled to a depth of 1 cm.

After that, the surface is ground until the unevenness is completely eliminated. Then it is necessary to eliminate concrete dust and soak the floor with polyurethane primer. An alternative to it is an epoxy analogue.

The prepared area is poured with a repair compound, and after hardening, the surface is again ground.

Loosening the top layer of concrete

Deterioration of a concrete floor can lead to loosening of its surface. If the destruction of this nature does not exceed a depth of 3 mm, then in such a section it is enough to remove the top layer of concrete by grinding. It is carried out until a durable surface that is thoroughly cleaned of dust.

With a slight destruction of the upper layer of the concrete floor, it is simply ground

Then the concrete is treated with special reinforcing and dedusting compounds that have a chemical effect. Their alternative may be polymer or polymer-cement compositions..

Thus, analyzing a number of reasons that lead to the appearance of certain defects on the surface of a concrete floor, the types of these defects, and elimination technologies, it can be concluded that the process of restoring a floor from concrete is quite laborious and responsible.

To carry out high-quality repair of concrete floors, it is necessary to take care of the availability of all necessary tools and equipment in advance. Directly during the restoration work, all available nuances should be taken into account and the technology must be observed. Otherwise, the result will be short-lived..