Laying laminate flooring on a wooden floor

Such a method as laying a laminate on a wooden floor is usually resorted to when the existing floor is no longer pleasing to the eye with its appearance, but is still suitable. Laminate in this case performs an aesthetic function, giving the old wooden floor an updated look. There are certain styling technologies, as well as a lot of nuances that should be considered when implementing them..

Content

- About the laminate: design, features

- Preparation for the upcoming work

- We buy material for installation

- Need a level foundation

About the laminate: design, features

Laminate has the form of thin 7-11 mm sheets (panels) (100-140 cm long, about 20 cm wide), along the edges of which there are special spikes and grooves for joining (connecting) with each other. Thanks to this design, it is very easy to assemble this flooring, even a beginner homemade can handle it.

The laminate consists of 4 layers:

The layers that make up the laminate

- Topmost – this is a protective layer, is a high-strength special film made of acrylic or melamine resin, in other words, a laminated film, by name of which the entire product was named. The top layer protects the decorative part of the laminate from all external influences and abrasion.

- Second layer – decorative, performing design functions. It represents a layer of paper on which drawings are applied under a tree, a stone, a tile.

- Third layer is the carrier – this is the “body” of the laminate board. It is made of fiberboard or HDF (this is a compressed pulp mass, very reminiscent of getinax – a dense cardboard impregnated with a special composition used in the radio industry). This is the toughest part of the coating, just in it are spikes and grooves designed for fastening together. The same component is a noise and heat insulator. The moisture resistance of the laminate board also largely depends on the quality of the carrier layer. If it is properly treated with moisture-resistant impregnations and has a high density, then the harmful effects of water and other liquids will be minimized.

- bottom layer It is stabilizing, protects the board from deformation and serves to increase rigidity. Sometimes a soundproofing substrate is glued to it, designed for additional sound insulation.

To complete the picture, we give the advantages and disadvantages of the laminate:

Benefits:

- Laminated panels are one of the cheapest flooring..

- The floor is easy to lay even without special skills.

- The panels connected by means of spikes and grooves (without glue) can be laid again (but no more than 3 times).

- Resistant to scratches, stains, shock, exposure to chemicals;

- It can imitate any, even the best types of wood, a variety of patterns and colors..

Disadvantages:

- The coating material is not natural, some of its types can cause allergies. Non-allergenic only those for which there is a special certificate.

- May burn toxins when burned..

- Laminated boards are “noisy”, the echoes of steps are clearly audible, which can only be partially eliminated with soundproof mats laid under the panels.

- This floor is almost impossible to restore.

- Low moisture resistance.

Preparation for the upcoming work

We buy material for installation

First of all, of course, you need to buy the laminated panels themselves. Before going to the store, measure the floor area. Laminate is sold in integral packages and indicates the area that can be covered with the amount of material that is available in them. There is one caveat: laminate need to be bought with a margin. Moreover, the number of panels purchased separately will depend on the installation method. If you plan to place the boards directly (in a checkerboard pattern), then the increase must necessarily be at least 5-8% of the total, but if you stack the boards diagonally, the margin will be 10-14%. The reason is that the laminate is laid “apart”: the boards of one row relative to the other are shifted by “half the length”. And one more thing: boards are not sold individually, even if you need only 2 additional plates, you will have to buy a whole pack.

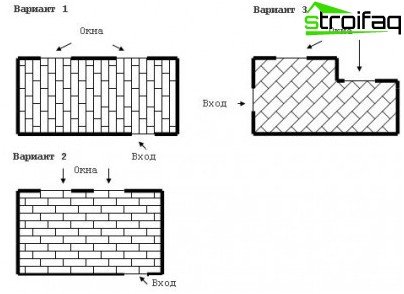

Layout options for the laminate on the floor: Fig. 1 and fig. 2 – directly (in a checkerboard pattern), fig. 3 – diagonally

When buying, pay attention to laminate classification:

- 21 – for home rooms where the intensity of walking is the lowest (pantries, bedrooms, etc.). Such a laminate serves no more than 2 years.

- 22 – for home rooms where the intensity of walking is average (for example, for children). Serves – up to 4 years.

- 23 – for home rooms where the intensity of walking is the highest (hallway, kitchen). Serves – up to 6 years.

It is worth noting that classes 21-23 are practically not used, with the exception of foreign options.

- 31 – for commercial halls (rooms) with the lowest walking intensity (meeting room, storage rooms). If used at home, it can last 10 and 12 years.

- 32 – for commercial halls (premises), where the intensity of walking is moderate (offices). At home, can lie up to 15 years.

- 33 – for commercial halls (premises), where the intensity of walking is the highest (shopping halls of stores). Service life in home premises – up to 20 years.

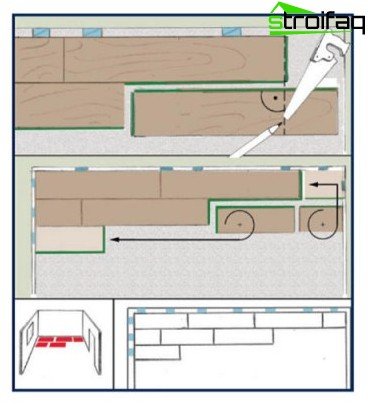

Laying the base under the laminate on the wooden floor begins traditionally: from a long wall without a doorway

Need a level foundation

The wooden floor under the laminate must be prepared. Panels should be laid on an absolutely flat horizontal surface. After all, a laminate is not a load-bearing coating, it should lie on something with its entire plane, preferably on some kind of damping (softening vibration) substrate, if the material is very hard. For these purposes, foam foam (thin foam polyethylene) or a special cork substrate is good. They will be additional sound insulators and heaters. For wooden floors, sheets of chipboard (particle board), consisting of sawdust, shavings, are usually used. Sheets are made by hot crimping. When using them, a damping substrate may not be necessary, because these sheets are much less hard than laminate (they contain 45% of a special binder), you can not be afraid of abrasion of the panels.

Chipboards are an excellent option, they give 2 advantages at once:

- are good heaters;

- give the floor extra rigidity, hide irregularities.

The sheets of the leveling layer of chipboard need to be firmly attached to the logs or draft basis

When laying sheets of chipboard should focus on the following rules:

- It is necessary to lay sheets of chipboard so that there is a minimum of waste. Thus, the first sheet is laid along the length of the room (it can be wide if the sheet is completely laid down, or if it will be cut no more than 20 cm). When laying the first sheet, make sure that its ends are firmly pressed against the walls of the room.

- Sheets are fastened with self-tapping screws with special countersunk heads or nails. If you decide to fix it with self-tapping screws, then before that you need to mark the surface of each sheet. It is through it that holes will be drilled, and only then through them screws will be screwed into the boards of the wooden floor. Make sure that each self-tapping screw is guaranteed to “drown”, not to bulge out the material surrounding it.

- When they finish attaching the first sheet, measure the distance from the end of the sheet to the wall. According to the received sizes, the second sheet of chipboard is cut (of course, if necessary). The cut sheet is laid on the floor, its end is pressed tightly to the end of the attached sheet, then attached to the floor.

Important! Before laying chipboard sheets, make sure that the wooden floor is dry and clean..

The specifics of laying on a wooden base

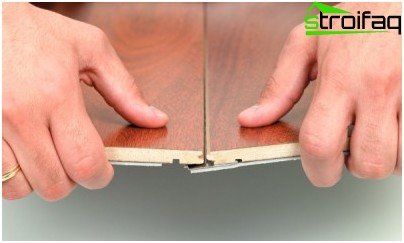

Each laminate plate has ridges (spikes) from 2 lateral faces and grooves and from 2 opposite ones. These grooves and ridges can be of completely different designs. From the simplest ones, for example, as in a lining (tongue-and-groove), to rather complex ones, folding into a “lock” (usually Click type).

If you purchased panels with a simple system, you will definitely need a special glue that will be applied to the groove. Glue must be bought special, designed for gluing laminate panels together. The system with a lock does not require the use of glue, and the laminate is mounted much easier and faster.

Joining a glueless laminate

Method-independent tips

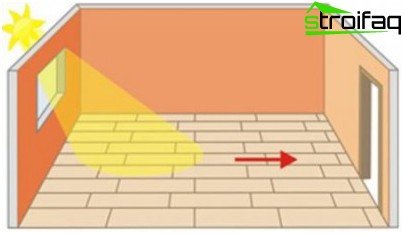

- It is necessary to lay the panels perpendicular to the window, so that the direction of light coincides with the direction of the laminate. The reason is simple: if the sheets are laid in the other direction, the joints between them will be much more noticeable, and this will negatively affect the appearance of the new floor. Sometimes, oblique laying of panels is practiced in order to create a rather unusual decorative effect, but this type of laying is quite complicated, the efforts made are far from always justified.

- Laying the laminate begins with measuring the width of the room. At the same time, the width of the last web in the row is determined, taking into account that at least 10 mm of clearance must be left on each side of the room. If the length and width of the room is more than 10 m, then the size of the gap is determined based on 1.5 mm per 1 meter. The gap is made in order to allow the laminate to expand, which it does under the influence of moisture and heat. If you do not leave a gap, then the canvas can stand on end. Sometimes, as a result of calculations, it may turn out that the width of the end panel in the row is less than 5 cm. Then you have to cut the panels so that the width of the first and last panels placed at the ends of the room are the same.

- It is better to start laying with the long side of the panel from the left front corner of the room, and along the direction of light. In addition, special wedges are installed along the wall to form a gap. They can be removed after work.

The direction of the light should coincide with the direction of the laminate.

Laying Cloths with Click Lock

Layout layout of the laminate in the room

- The first panel fits into the left front corner. The next panel is attached to it from the side of the end – to do this, insert the groove of one panel (at a 30 ° angle) into the groove of the other, and then lower them onto the floor, making the locks snap into place. Laying the entire row up to the end of the wall continues according to the same principle.

- Before starting laying the second row, you should think about displacing the end seams of the paintings by 30-40 cm from the previous row. This will allow you to distribute the load on the canvas more evenly. To get a checkerboard pattern, you need to cut in half 1 of the panels and start with it 2 row. You can do it differently: if when laying 1 row at the end, the panel was cut to obtain the required length, then at the beginning of 2 rows you can apply the remainder of the last sheet of 1 row.

When laying 2 rows, you can choose 1 of 2 ways:

- connect the panels with the ends, then dock the canvas with 1 row, while lifting 2 row at an angle. 30 gr., And then lowering into place, snap locks.

- connect the long sides of the paintings, and fasten the ends, knocking them with a hammer.

Laying adhesive laminate

This is a rather time-consuming process. In addition, it must be borne in mind that the glued floor can begin to be used no earlier than 11-12 hours after the installation. It is impossible to dismantle and then reinstall such a floor.

Glue application on the end of the laminate panel

Glue is applied to the ends of the panels, which are interconnected like a tongue and groove. Otherwise, the technology is similar to that used for glueless laminate. During operation, make sure that no adhesive protrudes on the surface of the panels. It must be removed immediately with a sponge or rag. After laying the first 3 rows, you need to wait 2-3 hours for the glue to seize.

When the laminate is laid, it is necessary to attach the baseboard (moreover, it is on the wall, and not on the floor). Skirting board perfectly masks all the small gaps remaining on the wall..

Thus, with your own hands, without the help of specialists, you can lay laminated plates in a house or apartment, giving the wooden floor an updated look.