Varieties and main characteristics of linoleum

Linoleum is a universal democratic flooring, represented on the market by a huge number of colorful, structural, textured options. You can buy now, as a budget homogeneous linoleum, as well as expensive natural marmoleum or heterogeneous coating, featuring a wide range of prices. The assortment offered by the market has this type of material with specific properties. All types of flooring, united by the common name linoleums, have characteristic differences, their inherent qualities, cons and advantages, information about which will help to choose the right material.

Content

- What labeling will tell

- Competent choice coverage

- Specific brands of linoleum

- The presence of the base and the number of layers

- Application Dependence

- Binder Composition

Modifications of modern linoleum differ significantly from obsolete unresectable analogues. Ecological purity, not peculiar to historical predecessors, is rightfully recognized as the dominant acquired quality. The decorative appeal of different grades of material allows it to compete adequately with that used for arranging living rooms, cabinets, bedrooms with carpet or laminate. Practical wear-resistant linoleum may well replace the ceramic tiles used for flooring in bathrooms, kitchens, showers, bathrooms.

Wear-resistant durable aesthetic linoleum of a new generation

Presented to consumers now, linoleum is a universal material, in no way inferior to its rivals, including in terms of operational terms.

The predominant number of products will last their owners from 7 to 10 years, individual material models can be used for 30 years. True, the service life will be equivalent to the values guaranteed by the manufacturer, provided that the installation technology is strictly observed. Which, in principle, is absolutely uncomplicated, since the simplicity and speed of installation is one of the main priorities of all types of linoleum.

What labeling will tell

When choosing material for arranging premises for a specific purpose, buyers are looking for an option that best suits their requirements and operating conditions. The correct technical specifications specified by the manufacturer during the manufacturing process and indicated in the documentation attached to the product will help to choose the linoleum correctly. Most linoleum companies now equip their product with graphic images and pictograms. The information on the package greatly facilitates the study of the qualitative features of a particular modification. Material labeling indicates:

- the scope of linoleum, depending on wear resistance, ability to resist indentation, abrasion;

- density directly proportional to strength and water resistance;

- insulating qualities, including resistance to the penetration of sound vibrations and the passage of heat waves;

- burning behavior of the coating;

- resistance to mechanical shocks.

A wide range of linoleums with various technical characteristics and operational qualities

Conditional graphic icons on the packaging will tell you whether it is possible to lay this product in the children’s room, on the stairs, in the dining room, whether this type of linoleum can be stacked above the “warm floor” system. Here you can find information on the stability of color, on the reaction of the material to chemicals and UV radiation.

Competent choice coverage

No matter how much manufacturers struggle to improve the product, there is no final solution to several basic problems:

- material deteriorates from exposure to low temperature,

- does not tolerate sunlight,

- a number of varieties give off a specific smell.

Therefore, PVC coatings are not recommended to be laid in production rooms in which the temperature can exceed 60 degrees. Material purchased in the winter should be allocated a day to adapt to room temperature. Linoleums made on a fabric basis, as well as made from natural components, should not be laid in bathrooms, showers, kitchens and near pools. It is recommended to focus on the selection of coatings for home improvement with the risk of fires for non-combustible linoleum types.

Specific brands of linoleum

In stores, you can now find linoleum variants with specific properties, information about which can also be obtained from the information on the package. Specific species are:

- antistatic type of this floor covering used for arranging rooms with a large number of electronic equipment;

- conductive material that promotes the removal of static electricity due to the presence of graphite inserts;

- electrodispersive type of linoleum, performing its function regardless of the level of humidity;

- flooring for laying in sports complexes, providing an optimal rebound of the ball, reducing the likelihood of serious injury;

- anti-slip linoleum, which provides reliable grip with a wet foot or shoe sole due to the introduction of quartz chips or due to the formation of a surface relief during manufacture;

- a medical variety, in the formula of which contains components that prevent the spread of fungal formations and bacteria;

- acoustic linoleum having a thickened foam substrate with excellent cushioning properties.

A specific kind of sports linoleum designed for equipping sports complexes

Graphic marking helps to correctly choose linoleum – characteristics, their meanings and specific qualities indicated by icons can be understood without translation. Material sold in domestic stores and on construction markets is subject to mandatory control checks, the results of which give fire and sanitary-hygienic certified confirmations. The product released in our country is tested according to the parameters.

The presence of the base and the number of layers

There are many questions for those who want to choose the right linoleum: what is the basis and whether it is at all, is it better to prefer layered or single-layer material? This is natural, because the structure of the material largely determines the future behavior of the floor covering, manifested in the process of use, its reliability and wear resistance.

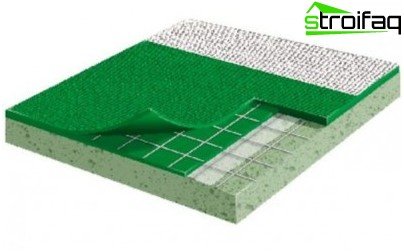

Regardless of the number of layers, linoleums are divided into base materials and types of coatings having paper, cork, jute, fabric, foam absorbing or heat-insulating base.

- Linoleum that does not have a basis is manufactured according to the technological principle of rolling and calendering by the rolling method. A mixture of polymer with additives enters the hot rollers, the thickness of the material is formed on the calendars. These are predominantly commercial types of flooring that can withstand a large load. Having one layer linoleums are also called homogeneous. They almost do not bend, but they are slightly worn out, it is difficult to cut them and it is impossible to burn them with a cigarette. Laying a homogeneous flooring of a commercial type is usually done by professionals who are fluent in the installation technologies of a rather thick inelastic material.

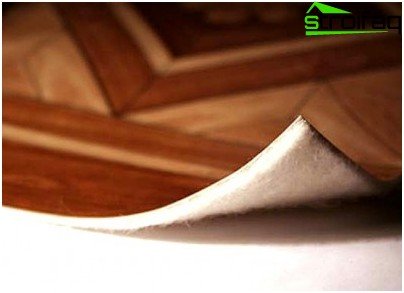

- Linoleum with a base is made in a completely different way. A hot mixture is applied to the prepared base, which, when cooled, acquires the required flexibility and hardness. Cold formulations may also be applied to jute, fabric, foamed polyvinyl chloride or other substrates. After they are heated, then the polymerization period passes. Having two or three layers of linoleum belong to the category of heterogeneous materials. The third layer of three-layer coatings is usually a polyvinyl chloride film that protects the material from external destructive factors. The second layer common to all flaky options determines the color of the material and its technical qualities..

Multilayer version of linoleum with a warming cushioning pad

The production of heterogeneous flooring is a more complex technological process, because the resulting material is much more expensive.

However, thin heterogeneous material has less weight, it is easier to stack. Subject to the manufacturer’s recommendation, a heterogeneous linoleum can be laid by a contractor without experience.

Application Dependence

- Household linoleum. Designed for arranging housing and public buildings with low traffic, the floor covering is distinguished by the minimum thickness of the working layer, elasticity, softness, and low weight. This is the thinnest kind of material, and therefore the least durable, the term of use is 5-7 years. The latest models do not attract dust, are inert to any household chemicals.

- Semi-commercial varieties of linoleum are stronger and more reliable than household modifications. Serve 10 or more years, are used for equipping offices, foyers and reception public buildings. This type, equipped with a substrate, holds the temporary static load well, restores the structural volume after its completion.

- The most durable and wear-resistant commercial linoleum – the characteristics of the material by values exceed the similar indicators of all types of these products. It does not bend at all, but it does not wear out even with intensive use, without any problems it keeps the weight of large machines. Next-generation commercial models last 25 years.

Semi-commercial linoleum – a combination of strength and aesthetics with an operational life of about 10 years

Binder Composition

All products offered by foreign and domestic suppliers can be divided into five large groups, the division of which is predetermined by a different composition of components:

- PVC linoleums are produced on a reinforcing fabric or foamed insulation base. They are represented by single-layer and multi-layer models. Negative quality – the possibility of shrinkage, which must be taken into account when laying.

- Alkyd or otherwise glyphthalic linoleums created using alkyd resin are characterized by high insulating properties and are equipped with a fabric base. Compared to PVC flooring, the material is more fragile and prone to cracking..

- Nitrocellulose-based colloxylin linoleum. This is mainly a single-layer material without a reinforcing substrate, a flexible, moisture-resistant type of linoleum. Among the negative qualities distinguish flammability.

- A two-layer linoleum made of rubber, the upper layer of which is made of rubber with an admixture of pigments and fillers, the lower layer of recycled rubber recyclable. It is characterized by water resistance and flexibility inherent in the properties of the starting components..

- Natural, the most expensive linoleum is made from natural ingredients. In the production of natural coatings, jute fibers, coconut straw, cork, limestone, sawdust with the addition of pigments, linseed oil, coniferous resin are used. The most expensive representative is the marmoleum, in the production of which only natural components and a jute fabric base are used. With the help of a marmoleum, residential interiors, rooms of medical and children’s institutions are equipped.

Environmentally friendly, safe natural linoleum

Common linoleum width

The traditional question that arises when calculating future expenses is: “How wide is linoleum?”.

- The flexible multilayer coating supplied in rolls with a printed pattern, plain and multicolor color can have a width of 1.5 to 4 meters.

- Linoleum with an insulating base is represented by products having a width of 1.2 to 3 meters.

- A vinyl coating with a fabric base is produced 1.6 – 3 meters wide.

- Rubber linoleum – relin is supplied in rolls, the width of which is 1 – 1.6 meters.

Information on the wide assortment range of floor coverings offered to the consumer under the generic name “linoleum” will help to choose the most suitable material for the arrangement.