Warming of wooden floors

Warming of wooden floors is necessary to increase the comfort of living in the house. This is especially true for residents of the first floors of multi-storey buildings, owners of country houses and other low-rise buildings. Indeed, such floors are bordered, as a rule, with cold undergrounds or soil, and if the floor is not properly insulated, then heat will constantly go through it. How to do it, what materials to apply – we will go further.

Content

- General principles of thermal insulation

- Properties of thermal insulation materials

General principles of thermal insulation

The general technology of warming wooden floors, the so-called skeleton, which, if desired, can be supplemented with something else, includes 5 components:

- Dismantling of the old floor;

- Installation of the rough floor;

- Covering the rough floor with insulating material;

- Vapor barrier coating;

- Installation of the finishing floor.

Properties of thermal insulation materials

Before moving on to the practical part and reviewing the technology wood floor insulation in more detail, we list the main materials used for this, their features and properties.

Insulating materials must meet the requirements listed below:

- possess resistance to compression,

- have low thermal conductivity;

- a long period to save thermal parameters;

- be easy to use, easy to install;

- easy to cut.

Types of insulating materials used for floor insulation most often:

1. Hydrophobized mineral wool. It has high sound and heat insulation, fire resistance, good resistance to mechanical stress. Insulation for floors from it is made in the form of:

- flexible mat. It is non-combustible, on one side it is covered with a layer of perforated paper (this side should face down when stacking).

- solid tiles. One side of it has greater hardness (it is marked with a blue stripe) and should be facing up when laying. Typically, these plates are used for single-layer insulation of the wooden floor of a house standing on the ground.

2. Extruded Styrofoam. It is characterized by low heat conductivity, low vapor permeability, durability, high strength level, good waterproofing properties, and is not biodegradable. It does not need to be leveled during installation, therefore, insulation work with it can be carried out in any weather. However, it is less fireproof than mineral wool, and can also be damaged by moles, mice, and other rodents. It must be fixed with foam sealant (handle joints).

The most common floor insulation scheme is laying logs with filling gaps with insulating material

Expanded polystyrene from mineral wool mainly differs in that the latter is more prone to water absorption. And if polystyrene foam is sometimes laid immediately on a concrete floor, since it does not require a waterproofing layer, then when laying cotton wool, such a layer may also be required as a vapor barrier.

An important parameter of any insulation is its thickness. For summer cottages, 50 mm is enough. If you plan to stay in the winter, then up to 200 mm.

As a vapor barrier material, you can use ordinary polyethylene, polypropylene sheets, vapor barrier membranes. They protect the insulation from moisture, which, if ingested, can reduce its thermal insulation ability. The vapor-proof wooden floor will last you longer. Such a vapor barrier as penofol has proven itself well. It is a foil foamed polyethylene. This is a very flexible and thin material, it does not allow moisture to pass, helps to retain heat in the house, and serves as an excellent sound insulation. It is necessary to lay it with foil inside the room.

We warm a wooden floor in a private house

In private houses with wooden floors, wooden logs (horizontal bars) are used as floors. Such a floor must be insulated, through it the heat goes away very quickly.

To warm it, you will need:

- boards 20 mm thick (as much as possible);

- wooden block necessary for fixing the vapor barrier;

- insulation directly;

- vapor barrier.

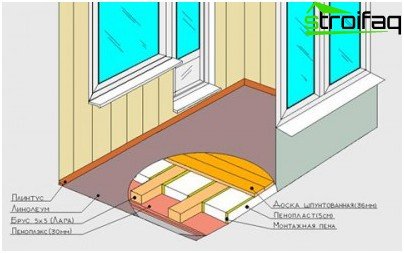

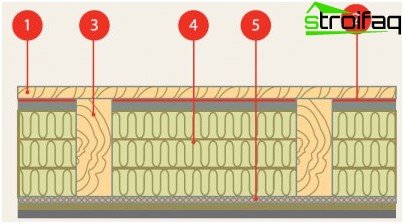

1. A covering from boards or OSB 2. Vapor barrier, waterproofing of a heater 3. Wooden logs 4. A heater for a floor of the first floor 5. A covering from a board or a wire mesh

Technology of warming a wooden house

- Flooring is removed.

- On the outside (i.e. bottom), auxiliary boards are fixed along the entire length.

- Logs are installed with an approximate step of 0.6 m or 1 m. For additional protection they are covered with antiseptic compounds to prevent rotting of wood.

- Insulation is placed on the boards between the lags. When using a solid insulation, for example expanded polystyrene, all joints are treated with polyurethane foam so that there are no gaps.

- Then, a vapor insulator is laid over the insulation, which is attached to the logs with the help of a bar (20×30 or 30×30). For better vapor barrier joints need to be glued with metallic tape.

- The main floor is laid.

There are technologies for warming a wooden floor, in which an impromptu mesh is used, consisting of a solid fishing line. It is fixed on nails driven into beams and is used instead of the rough floor. On the one hand, this way you can save on building materials, on the other hand, there is a high probability that the fishing line under the weight of the insulator will stretch over time. Therefore, this method is not reliable.

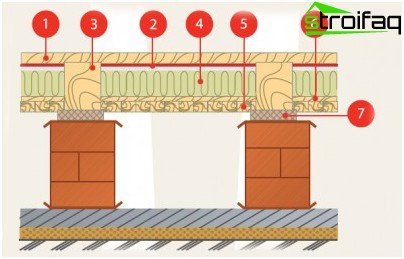

Sometimes thermal insulation of the wooden floor of a private house (ground floor) on the ground or above the underground is arranged along logs that are laid on brick columns. Logs are laid on a wooden strip passing through the waterproofing layer. Insulation plates are placed in the gaps between the lags and protected with a waterproofing coating.

1. Covering the ground floor from boards or OSB 2. Steam insulation, waterproofing insulation 3. Wood logs 4. Insulation for the floor of the first floor 5. Board flooring 6. Sheathing from boards 7. Antiseptic laying, waterproofing

Another point worth noting. Sometimes, to insulate a wooden floor, a waterproofing layer is laid from below, it is located up to the draft floor. But this is a rather costly approach. When using, for example, expanded polystyrene, there is no need for waterproofing.

We warm the wooden floor in the apartment

It is easier to insulate wooden floors in an apartment than in a private house. It is necessary:

- Peel Off Layer.

- Place logs on the floor slab.

- Between the lags place a heater

- Close all joints formed between the insulation and lags (if mineral wool is used, then this is not necessary).

- Lay a vapor barrier.

- Attach flooring.

As seen in warming of wooden floors and in a private house, and in the apartment there is nothing fundamentally complicated. Even a beginner in the field of construction and repair is able to master such a technology. The main thing is to carry out the plan, strictly following the instructions.