The device of wooden floors

Many people are sure that the plank floor is a completely non-modern coating, they say, for the decoration of housing you need to give priority only to the latest synthetic materials. One can argue with this opinion, because a properly laid flooring from boards does not creak, it serves for a long time. It is also warm, beautiful, easy to care for, and if there are flaws, then they can be repaired with your own hands. Such a floor looks great in a cottage, a country house, only you should not forget about harmony with the interior.

Content

- Practical wood selection

- The nuances of laying a wooden floor

- Board decking

- Draft base construction

- The design of the lag

- In one or two layers?

Practical wood selection

Laying a plank floor begins with a careful selection of material. Coniferous boards, for example, pine, spruce, fir, larch, are best suited for this purpose. This wood has an exquisite appearance, it is durable and durable. If in the future the plank floor will be varnished, rather than paint, it is necessary to choose light wood with a natural fiber pattern and strong shine. It is believed that the most beautiful texture has mahogany and walnut. That’s just these materials are quite expensive, so if such costs are unacceptable, then you can opt for oak – the price is lower than generally recognized decorative species and the texture is pretty decent.

Conifers

The next point – for the flooring you need to use exclusively dry boards. Working with raw or overdried wood is unacceptable, since the boards will warp, cracks will occur, which means that the work will go down the drain.

Another important nuance is the implementation of protective measures, that is, the processing of wooden structures, preventing the development of rot and insect damage.

Important: if you ignore the stage of treatment with antiseptics, the consequences will be extremely disappointing: the floor will become unusable in a few years.

Especially destroying and spoiling the wood putrefactive fungi, quickly destroying cellulose, boards turn into dust. Fungi that feed on the sap of wood cells are also of great danger. Wood affected by these microorganisms changes color, becomes green or bluish from mold.

It is in the conditions characteristic of residential premises that mushrooms are active, therefore, logs, gaskets, which are used to arrange a boardwalk, are certainly treated with antiseptic agents. Similarly, they are coated with an antiseptic on the underside and the board, the front side does not need such a process, because it will be applied with paint, varnish or mastic.

For this purpose, for example, sodium fluoride, ammonium fluorosilicate is optimally suitable. Experienced builders advise using the drug not only with an antiseptic effect, but also protecting from fire and increasing the life of the nails and bolts that hold the boards together..

The nuances of laying a wooden floor

The technology of laying a wooden flooring depends on many factors, starting with the thickness of the boards, such as the primary base, and ending with the unwillingness or desire to reduce the height of the room. In any case, it is advisable to start laying the flooring only after the successful completion of the main work. That is, windows and doors are installed, the ceiling and walls are finally finished.

Important: during installation, room humidity should not exceed 60%, but too low a percentage is unacceptable.

The device of the plank floor consists of the following steps:

- lagging on a prepared basis;

- board flooring;

- sharpening sagging with subsequent cleaning of dust and chips;

- installation of ventilation grilles and baseboards.

Board decking

It is best to lay a plank floor at the end of the heating season: in summer, the wood absorbs a lot of moisture, so in winter the boards will dry out and later cracks will form between them. Well, if, nevertheless, the floor is laid in the summer, then it is necessary to choose a period preceded by hot weather (1-2 weeks).

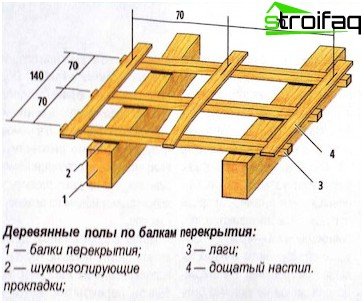

Laying boardwalk on logs

Draft base construction

Flooring from boards on the ground is made on a special concrete surface or on separate supports that are not connected in any way with structural elements. Such a device allows you to isolate the floor from the walls of the house, that is, to reduce the transmission of vibration and sound vibrations. However, such a design requires good waterproofing, since moisture present in the ground is very detrimental to wooden materials..

For columns made of red brick, concrete preparation is a good basis: crushed stone compacted into the ground, compacted soil, always with an undisturbed structure. Such columns are installed in rows, the gaps between them depend on the thickness of the flooring. Then logs are laid on them, under which a roofing layer and antiseptic pads are laid.

Important: it is not recommended to install wooden poles, as they quickly rot.

Often the underlying layer of concrete is uneven, there are hollows and bumps on it, and there may be level differences. For this reason, you must first correct all existing defects, otherwise the floor will be uneven, and the boards will creak, bend and “walk”. To do this, it is necessary to treat the concrete surface with a metal brush or a peeling machine. All garbage formed should be cleaned and treated with a primer..

The design of the lag

The device of wooden floors starts with laying the extreme lags near the opposite walls (a gap of 15-25 mm), then all the others follow. They are located across the direction of light, except for rooms with a certain movement (corridor), then the logs are laid across the aisle, and the planks, respectively, along. In this case, the air space under the floor should not communicate with smoke and ventilation ducts, as well as in rooms with an area > 25 sq. m. apply additional separation by partitions into closed compartments.

As for the lag, they fit strictly at the same level, while the distance between them varies between 700-1000 mm. Large gaps are undesirable because magpies can sag. The bars are used as logs, the correctness of their alignment is checked by a two-meter rail (it should lie on all logs without gaps), and horizontalness – by the level that is installed on the rail.

In one or two layers?

The flooring can be laid in one / two layers. The second option is much more practical, since the floor holds the heat much better in the house. When arranging a two-layer flooring, first of all, a black floor from non-planed boards (thickness 25 mm) is equipped. These boards are located in relation to the lags at 45 degrees and are firmly nailed. And then a clean floor is laid, while it is good to lay cardboard between the layers.

Now that the lags are stacked, you can begin to lay out planed boards for marking.

Important: adjacent boards are selected so that the resulting gaps are the smallest (1 mm).

If necessary, the boards are cut so that the joints are directly on the lags. A gap is made between the outer walls and boards (width 20 mm), between the inner walls – 10 mm: so that the boards do not rot from the cold walls, and also have a margin of space (with excessive moisture, expansion is possible).

With a preliminary layout, all boards are inspected once again for defects: cracks, stains of resin. Bad boards are either completely rejected or used in dark rooms (pantry).

Lag setting

Boardwalk laid in annual layers necessarily in different directions. This rule should be especially adhered to when using wide boards. Then the boards are numbered, so that later they fit quickly, without re-cutting.

At a short distance from the wall, the first board is laid, which is fastened with nails 100-125 mm long (2 in each board). The best solution is to drive nails with an inclination, and the hats must be flattened, drowning in the thickness of the board.

Then a second one is attached to the first board, at a distance of 5 mm from the edge of the extreme board, an ordinary bracket or Smolyakov brackets are driven into the logs. A safety bar is inserted into the resulting gap, and then a wedge is driven in. Due to the fact that the wedge is driven in with a certain force, the edges are pressed tightly, that is, the boards are rallying. After nailing the staples, the staples are removed and the following boards are laid. Etc.

At the end of the flooring, the joints of the boards are attached so that they are in the same plane and are even.

Important: to eliminate minor differences at the joints under the logs, cardboard, roofing felt, roofing (categorically not chips).

The remaining gaps between the floor and walls must be covered with skirting boards or fillets – with specific profiled slats of complex or simple shape. Skirting boards with bevels and grooves adhere very well to the walls, but in this case the ventilation of the boardwalk is disrupted, so special ventilation grilles are arranged in the floor.

Important: the most convenient and practical skirting boards with softwood filigree.

For the best functionality, the free space between the laid logs should be filled with insulation, and at the same time lay various communications under the floor. It is also necessary to focus on the fire safety of the structure. As for the direction of laying the boards, it depends on the designer’s idea, working conditions, the main thing is not to forget the rule – the boards must be placed perpendicular to the lags.

Important: recently, instead of nails, builders are increasingly using self-tapping screws.

Floor joists

This floor provides for the use in the role of load-bearing elements of the beam, which serve as the basis of the ceiling. The advantage of such a floor covering is the reliable isolation of structural elements from the ground. In addition, such a design increases the strength of the overall frame of the house. But there is also a significant drawback, which consists in rigidly fixing the beams with the crowns of the house. This rigid structure is characterized by high noise, because all vibrations, sounds are transmitted from the floor through the beams to the walls of the building. Therefore, it is undesirable to arrange a plank floor directly along the floor beams, using them as logs.

Boardwalk on beams

The increase in noise level partially helps to avoid the use of insulating gaskets made of rubber, impregnated with antiseptic felt and other vibration damping materials. The main method of dealing with “noisy floors” is to install additional lags across the beams, under which specific sound-absorbing pads are laid.

Sanding wood flooring

To align the wooden flooring, manual and floor grinders are used. First you need to remove everything that is not nailed from the surface and carefully sweep the floor.

Important: it is necessary to check whether there are nails on the floor, metal brackets, so as not to damage the abrasive tape.

Then you should go around the floor and check for defects that need repair before grinding.

This work is noisy and very dusty, so you need to use a protective mask and protection for eyes, ears.

Boardwalk Tools

The machine must be moved along the floorboards to avoid splinters. During grinding, do not press hard on the machine, because a significant layer of wood is sanded. The process begins with the application of the largest skin, and ends with a smaller.

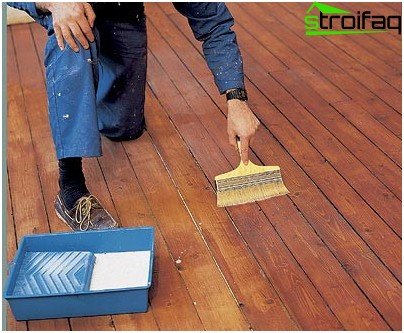

Floor painting

First you need to vacuum the floor well, and then you can start painting. It gives the floor extra warmth and also prepares for further decoration. For painting, you can use a brush (apply water-dispersed paint along the boards) or a spray gun. After drying, the floor becomes lighter, but it will get a saturated beautiful shade after applying a transparent varnish. Resistant nitro-varnishes are unsafe for health, and uncomfortable to use, so they are replaced by single-component acrylatex, polyurethane compounds that are diluted with water. They are easy to apply, practically odorless, dry quickly..

Floor painting

Basically, two layers of varnish are applied, the first is not very thick (no need to try to fill the cracks with it), the second – after 2 hours.

Important: if a third one is needed, then before applying the varnish, the surface should be sanded with a medium-grain sandpaper.

Undoubtedly, laying wooden planks is a process that requires certain carpentry skills and the availability of special tools (a cutting machine, a nail hammer). But subject to all the rules, you can qualitatively lay the floor, which will not creak and will last a long time.