The installation of high-quality floors is considered an obligatory measure, which determines the reliability and duration of operation of a future building. Conventional concrete structures that have not undergone special processing are not ergonomic, it is dirty and dusty in such rooms. If the requirements of strength and cleanliness are important to you, then it is advisable to lay polymer or bulk industrial floors.

Content

- Industrial flooring requirements

- Robust multi-layer construction

- Classification, differences, purpose

- Concrete industrial floor device

Industrial flooring requirements

The industrial floor is a building structure on which the entire production process and the activities of people take place. Designs and materials of industrial floors are prescribed based on the loads from the stored cargo, the intensity and type of mechanical effects of floor vehicles and dust separation in accordance with established standards.

General technical requirements for industrial floors are as follows: the design must resist bending, compressing and stretching, impact and abrasion. The floor must withstand aggressive chemical factors – low or high temperatures, water, oils, alkalis and acid solutions.

Floor for industrial and industrial buildings

According to technological requirements, the industrial floor should have a smooth, but not slippery surface, and also provide convenient and safe movement of vehicles and people. In addition, the floor during operation should not have a harmful effect on human health, that is, the structure should not emit hazardous gases, dust and odor.

Static electricity charges should not form on the surface of the industrial floor, and in some cases the floor simply has to be an insulator. There are also operational requirements for industrial floors – the material must be able to be repaired and can be cleaned quickly and easily..

Robust multi-layer construction

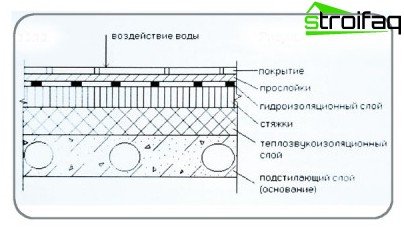

Industrial concrete floors consist of several layers. The soil base acts as a natural or artificial floor support, which perceives all the loads that are transmitted from the floor. Next is the preparation – the underlying layer, which distributes the load on the soil base.

Thermal insulation is needed to reduce the overall thermal conductivity of the floor, and sound insulation prevents impact noise from entering the room and from it. Waterproofing – a layer that prevents the penetration of sewage and other liquids through the industrial floor, and also protects the entire structure from groundwater.

What layers does an industrial floor consist of?

The next layer of the industrial floor is called screed. It serves to level the surface of the underlying layer or overlap, it is necessary to give the coating a given slope, to cover different pipelines and to distribute loads on non-rigid underlying layers of loads.

An interlayer is usually called an intermediate layer of the floor, which binds the coating to the underlying layer or serves to cover the elastic part. The coating is the top layer of the floor that is directly exposed to operational influences.

Classification, differences, purpose

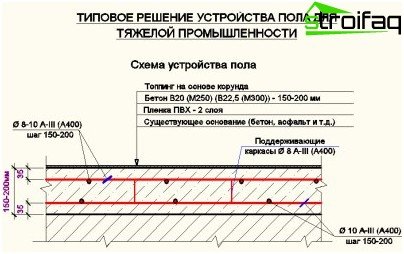

Industrial floors come in several forms. Concrete floors with a hardened top layer have established themselves as a durable, reliable and dust-free coating. Used for industrial buildings, garages, car washes and car services.

Industrial bulk floors are not afraid of active mechanical and chemical influences. They are aesthetically more attractive than toppings. Similar designs are widely used in public buildings – floors for office, shopping center, office building. Polymeric bulk floors, due to their resistance to aggressive environments, are found in enterprises of the food and pharmaceutical industries.

Industrial floor at a car dealership

A monolithic mosaic floor, which is made of magnesia concrete, is excellent for high-intensity and high-load operation modes. Magnesian floors are used for industrial buildings and structures of various industries, serve as high-strength seamless floors for warehouses and parking lots..

Mounted floors are most often used in administrative and office premises, as well as public buildings. These are office floors, floors for shops and retail space, cafes and restaurants, utility and technical rooms.

Concrete industrial floor device

If you plan to build a new production building, it is worthwhile to think carefully about the laying and arrangement of industrial floors. Traditionally, this type of work requires great accuracy during installation and considerable experience in the construction field. Technologically, the process is not easy.

Industrial floor arrangement

Industrial concrete floors can be laid on top of soil or an existing concrete base. Laying a concrete floor on the ground begins with a thorough preliminary compaction of the soil, which is carried out over the entire area of the room. According to the technology, the next step will be laying a sand cushion. Its thickness depends on the type of soil. A compacted gravel pillow is placed on top of the sand.

If industrial floors are laid on top of an old foundation, this also requires careful preparation of the foundation. It is customary to inspect for cracks that should be expanded and filled with a special repair compound. If the condition of the base does not allow repair work, it must be dismantled. The base must be leveled if it has sharp changes in height.

The presence of waterproofing in concrete floor technology depends only on the initial design. The process is carried out using polymer membranes or bitumen waterproofing. If the floor is poured in a large area, then the territory must be divided into “maps” – rectangles of a specific size, which are determined by the pitch of the columns. The optimal size is 6 meters.

Industrial floor tool

On the prepared surface, you need to place the reinforcing mesh, which is superimposed between the cards with the necessary overlap and fastened with a soft wire. Then it is necessary to fill the concrete floor taking into account the mobility of the mixture.

Industrial flooring – topping distribution

The installation of a concrete screed on an industrial floor requires a careful approach to leveling, which should be done with the help of vibration rails – special tools. At this stage, the addition of concrete is allowed. Next, grout the concrete surface and apply topping. Used concrete coater.

First you need to conduct an initial surface cleaning, after which it is worth scattering topping. It is important to distribute the substance as evenly as possible over the surface of the concrete screed. As soon as the topping absorbs moisture and the surface darkens, rough screed of the industrial floor should be grouted – immediately distribute the remaining topping.

Finishing sanding should be done at the moment when the person’s legs will leave a trace of 2 mm deep on the surface of the screed. For this procedure, all the same concrete-cooling machines with finishing blades are used, which are able to gradually change the angle of inclination. The construction of a concrete industrial floor will come to an end when the floor receives a characteristic concrete shine. If desired, you can apply a dust-free coating and iron the concrete floor.

As seen, concrete flooring It is a specific time-consuming process, but pouring concrete industrial floor with your own hands is still feasible. Following the instructions, as a result, you can get excellent coverage, which is suitable for any industrial or industrial building.