How to insulate the floor in a private house

One of the most important components of a comfortable home is a warm floor. This is especially true for families with small children. Ideally, you need to take care of floor insulation at the construction stage. If you purchased housing in the secondary market or made mistakes during its construction, you will have to warm the finished floor. From this article you will learn how to properly insulate the floor of a new house and how to fix the mistakes of builders.

Content

- Rules for warming floors

- Floor insulation in an old house

- Selection of insulation

- Warming of a wooden floor

- Thermal insulation of concrete foundation

- Floating floor insulation method

- Underfloor heating device

Rules for warming floors

If you yourself are engaged in the construction of a new house, pay special attention to the correct formation of the rough and finish floor. Do not try to save – it will not lead to anything good. Most likely, in a few years you will have to correct your own mistakes. And this is not only additional costs, but also significant inconvenience.

If there is no basement under the house, it is quite simple to warm it.

- In the case when groundwater lies at a depth of less than 2 m, it is necessary to start with waterproofing.

- Then install the rough floor.

- The next step is the laying of thermal insulation material. It can be mineral wool, expanded polystyrene or expanded clay.

Important! When insulating the floor with mineral wool, it is necessary to lay a layer of waterproofing material under it. Minvata easily absorbs moisture and quickly collapses under its influence.

- We mount the final floor from a planed board, chipboard or OSB-plate.

Floor insulation in an old house

Of course, you can completely dismantle the floor in the old house and rebuild it, but more often it is not practical. Such a cardinal solution to the problem will be needed only if the ceilings in the house are low and it is extremely undesirable to raise the floor level.

Selection of insulation

In order to decide how to insulate the floor in a private house, it is necessary to consider all the proposals of the modern building materials market. The most common thermal insulation materials for the floor include polystyrene, mineral wool and expanded clay. Let’s look at all the advantages and disadvantages of each of these heaters.

Expanded clay – an inexpensive and environmentally friendly material. Its indisputable advantages include longevity and moisture resistance. However, the thermal insulation ability of expanded clay is much lower than that of expanded polystyrene or mineral wool.

Polyfoam – the made foam polymeric material, for 90% consisting of air bubbles. Its thermal conductivity is much lower than that of expanded clay, and its resistance to moisture is almost the same. The only significant drawback of polystyrene foam is its low environmental friendliness. Often during operation, the foam emits phenolic compounds that are very harmful to health. When heated strongly, this material melts and emits toxic smoke..

Mineral wool is one of the most popular insulation materials. Depending on the feedstock, glass and stone wool are distinguished. In everyday life, they use one and the other. The thermal insulation properties of this material are very high. In addition, mineral wool is absolutely harmless to humans. Its only drawback is a significant increase in thermal conductivity when wet. That is why when insulating the floor with mineral wool it is necessary to use waterproofing.

Warming of a wooden floor

Before as insulate the floor in a wooden house you must make sure of its strength. To do this, remove a few boards and check the condition of the lag. If they are not damaged by rot or parasites, put the boards in place and proceed with floor insulation.

- First you need to provide waterproofing insulation. To do this, cover the entire surface of the floor with a glassine or roofing material.

- We install a beam 50-60 mm thick directly on the old floor and fix it.

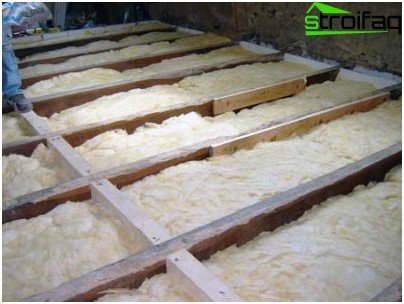

- Then we put insulating material in the space between the lags.

Insulation of the floor at the cottage with mineral wool requires a waterproofing layer on both sides of the insulation material

- On the beam we fill the finishing floor from the edged board or USB-plate.

Thermal insulation of concrete foundation

If a concrete floor is poured into a house, it is as easy to insulate it as a wooden one. You can do this using the same technology with some additions. If you plan to lay a wooden finishing floor, you need to proceed according to this scheme.

- First of all, the concrete floor should be thoroughly cleaned with a vacuum cleaner or a broom..

- Next waterproofing.

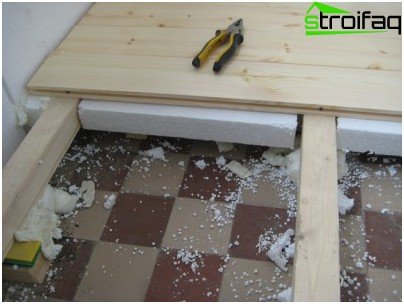

When insulating the floor with foam, it is necessary to completely eliminate the penetration of harmful toxins released by the material when heated

- Then we put wooden logs, the space between which is filled with insulation.

Important! When insulating the floor in the corridor logs should be placed perpendicular to the movement.

- We mount the final floor.

Floating floor insulation method

A characteristic feature of this floor is a multilayer structure, in which the last layer is a cement-sand screed. This layer is not attached either to the walls or to the base, which determines the name of this method of insulation.

- Waterproofing material is laid on the old concrete floor, then insulation, again a layer of waterproofing.

Layout of layers in the insulated construction of the “floating floor”

- Then the screed is poured, the thickness of which should not be less than 60mm.

For concrete pouring, it is better to use extruded polystyrene foam. Despite the apparent fragility, this material can withstand a load of up to 30 tons per 1 m2. And thanks to the impermeability of the cement mortar, the main disadvantage of the foam plastic is overcome – the possibility of releasing volatile chemical compounds.

Underfloor heating device

The technology of electric underfloor heating is becoming increasingly popular. And it is quite justified. The indisputable advantages of the “warm floor” system include uniform heating of the room, and the disadvantages are the bills for electricity consumed..

If you still decide to use this technology in your home, it is not necessary to hire specialists for its installation – you can handle it yourself. Let’s look at a phased plan for installing an electric floor heating system.

- First of all, it is necessary to clean and level the subfloor.

- Then lay a layer of waterproofing. If you are sure that your old floor does not “draw up” moisture, waterproofing can be neglected.

- The next layer should be heat insulating material. In apartments, foilizol is most often used. In an apartment building, under the floor slab, there is another apartment, and, consequently, heat loss is much less. For a private house, it is necessary to provide a large degree of thermal insulation. For this, as a rule, extruded polystyrene foam is used..

- A cable is placed on the heater with a snake. You can also use a heating system, consisting of special mats. It is much easier to install, but much more expensive..

- When the system is connected, it remains only to fill the floor with a concrete screed, about 50 mm thick.

The system can only be operated after the concrete has dried completely, that is, no earlier than 3-4 weeks later. It is necessary to increase the heating temperature gradually.

The heating system is controlled through an electronic relay with a temperature controller. Most models of these devices have the ability to program, which eliminates the need for homeowners to constantly intervene in the operation of the system and the extra energy costs.

In addition to electric underfloor heating, there is also the possibility of installing a water “warm floor”. When heating is carried out thanks to pipes with a coolant laid under a concrete screed. Such a system is much more expensive at the design and installation stage, but much cheaper to operate. The most profitable to install water floor heating in houses with gas independent heating.

How to insulate the floor in the country

In principle, to warm the floor in a country house, you can use any of the methods described above. The only feature of such a room that must be taken into account is irregular heating. If you do not live in a country house all year round, and in the winter sometimes come for the weekend, it is necessary to insulate the insulation from the inside. As a rule, in such houses it is not recommended to use mineral wool as thermal insulation, since even with a slight ingress of moisture this material very quickly becomes unusable.

Before you start insulating the floor in a private house, check if your foundation is sufficiently insulated. Sometimes the insulation of the foundation allows you to do without large-scale internal work.

As you can see, there are a lot of ways to insulate the floor in a private house or in the country. Which one to choose is up to you. But remember that according to research, almost two-thirds of the thermal energy leaves your home through the floor. Money spent on floor insulation will be saved on energy in just a few years. And all these years, life in your house will be more comfortable..