Which insulation is better for the floor

“Keep your feet warm” – the ancients claimed, assuring that in the area where the head is located, the ambient temperature should remain cool. In reality, in a housing located on the first floors of multi-storey buildings and country cottages, the floor temperature is often 2-3 degrees lower than that measured at the average person’s height. Reason: improperly selected insulation for the floor and errors in calculating the power of the insulation layer. It is also possible that there have been violations of the technology of equipping the lower floor with insulation.

Content

- List of requirements for insulation

- Insulation for the floor and its strength

- Thermal Insulation Life

- Comparison of heat engineering qualities

- Heater weight – a weighty criterion

- Focusing on the steam-conducting effect

- We evaluate the safety of insulation for the floor

An illiterate choice of heat-insulating material leads the list of causes of heat leaks through the floor surface. It is substantiated mainly by the lack of knowledge about the operational properties and technical characteristics of a particular type of insulation. Before giving preference to a certain type of thermal insulation material, you should consider:

- upcoming operating conditions;

- the temperature and condition of the soil base, laying the foundation or containing the basement;

- stable or periodic groundwater level if available;

- the likelihood of biological effects, the appearance of a destructive fungus, damage by rodents;

- insulation compatibility with the main building material.

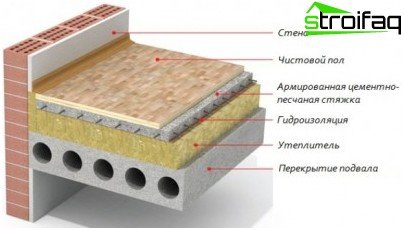

Insulation of the floor with the help of thermal insulation material is performed according to this scheme

Most often, the choice of material for floor insulation in an apartment or in a country house, the owners focus on the advice of friends, forgetting about the differences in the working conditions of the insulating layer. However, the temperature regime, the degree of load, ground moisture affect the long-term service of materials, on the preservation of the structure and indirectly on the insulation parameters.

Therefore, the question, reasonably asked by future users: “what insulation is better for the floor?”, The answer is ambiguous. It can only rely on the specifics of a particular structure.

List of requirements for insulation

In an extensive range of heat-insulating materials for equipping the design of the lower floor, the most popular are practical inexpensive mineral wool and polystyrene foam with a higher cost. Often the owners of apartments or suburban mansions prefer effective cheap glass wool. In addition to the difference in price, they have differences in technical characteristics and inherent in each of the insulation properties. The material used to increase the heating technology of the floor in housing should characterize:

- high strength parameters, since the floor is subjected to maximum load;

- maximum service life necessary for the work of the material insulating the most conservative, rarely updated floor surface;

- Superior insulating properties that reduce heat loss to minimum values;

- weight of thermal insulation material;

- low moisture absorption;

- steam conducting effect;

- insulation resistance to fire;

- safety and a healthy environment;

- the convenience of working with the material, affecting the timing of its installation and consumption.

An objective comparison of technical data and the specific properties of each of the materials will help determine the choice of insulation for the floor.

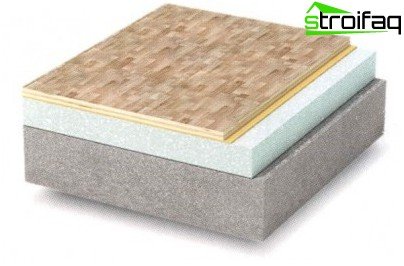

Extruded polystyrene foam in the simplest half-floor system

Insulation for the floor and its strength

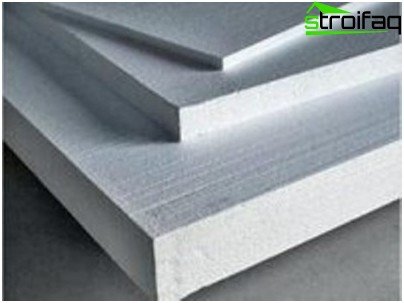

According to the strength criteria, expanded polystyrene foam obtained by extrusion technology occupies a leading position. The dense peculiar structure of the material with low weight withstands the maximum load. Unlike glass and stone wool, polystyrene foam is not fragile. It can be cut without any problems and excessive losses into elements of any configuration and size, necessary for laying in rooms with original architecture. In terms of strength, a staple fiberglass insulation is ahead of mineral wool, for the manufacture of which natural igneous rocks are used.

Glass wool – a budgetary insulation for a floor

Thermal Insulation Life

They depend on the reliability of the manufacturer and the terms of the guarantees provided. Equally important are the operating conditions. Mineral wool, for example, with too high a level of vaporization, with constant exposure to water, as well as when the temperature rises, can lose structural bonds, delaminate or crumble. Extruded polystyrene foam works excellently in difficult conditions, without losing the height of the original technical qualities. Because expanded polystyrene – the best insulation for a warm floor, and the most rational option for arranging socles, basements, foundations located in the groundwater flow zone, and the lower floors combined with them.

Comparison of heat engineering qualities

According to the criteria for heat conservation, the entire range of products intended for flooring in the initial state is equally effective. However, the cellular structure of expanded polystyrene protected from moisture provides stability of indicators. Glass and mineral wool have a fibrous structure and can absorb moisture. And water, being an excellent conductive medium, increases thermal conductivity, sometimes contributing to a decrease in insulation characteristics by 15-20%. Moreover, fibrous heaters absorb moisture from the surrounding soil, adsorb it from finishing and building materials, do not resist vapor diffusion.

Most often, when warming building structures with fiberglass or mineral wasted products, homeowners have to install ventilation equipment and climate systems. So the savings due to the low price of this type of insulation often becomes imaginary.

Heater weight – a weighty criterion

This is a good argument for those who do not want to spend surplus funds on the construction of a powerful foundation. The lightest polystyrene foam provides an opportunity to correctly reduce the construction budget with correct calculations of the thickness of the material layer. In addition, the heavy weight of mineral wool and staple fiberglass increases transportation costs and the cost of expensive manual labor.

Extruded polystyrene foam – the most rigid durable and the lightest insulation for the floor

Focusing on the steam-conducting effect

Cotton wool made from natural organic matter or glass allows the steam that occurs during residence to pass through. This quality is favorable for warming log houses and timber structures, the priority of which is the optimal steam-conducting effect. Warming of wooden buildings and roof structures with expanded polystyrene is not recommended by building codes, as it will eliminate the main advantage of wood. The priorities of the mineral thermal insulation material are supplemented by equipping one of the sides of the insulation with paper impregnated with flame-retardant flame retardants and increasing stiffness.

Installation and insulation of the “warm floor” system in a wooden house is most often preceded by the installation of expanded polystyrene under the screed

However, when choosing the “warm floor” design as the main heating system, the installation of expanded polystyrene is quite acceptable. This insulation is laid for the floor under the screed, and it is made of non-combustible materials. That is, the access of the flame to the insulating material is completely excluded. Therefore, many owners of wooden cottages equip houses made of wood in this way. This is the only option that allows you to economically use the space, completely hide the heating equipment.

We evaluate the safety of insulation for the floor

Expanded polystyrene, produced by leading manufacturers, on the basis of tests receives hygienic certificates that assure its safety. They are released toxins only in the combustion process, which is characteristic of almost all materials. But under normal operating conditions, there is no violation of sanitary and epidemiological standards. In the process of production of mineral wool and glass wool insulation, phenol-formaldehyde resins are used. When breaking structural bonds, these insulating materials can also emit silicate dust..

Bottom line: choose by comparing

Comparing the properties of the most popular types of insulation for the floor, you can correctly assess and find a balance between the advantages and disadvantages, learn and understand how to choose a insulation for the floor that meets the requirements of the owner and meets the operating conditions. After weighing the pros and cons, you need to choose a material with a more compelling list of consumer qualities that are personally priority for you. In this way, the selected material will create a comfortable atmosphere in the house, will achieve a significant economic effect in the heating season.