Overview of insulation

“My home is my fortress,” – today, unfortunately, this cannot be said about our living quarters. When they built most of the housing stock, no one thought about how to keep heat, and even more so to save. So it turns out that our “Stalin”, “Brezhnevka”, “Czech” and the rest of the housing are far from energy-saving technologies. Corner apartments, apartments on the first and last floors have long been generally considered cold. Moisture, cold, dust enter apartments through cracks, interpanel seams and even walls. In order to avoid all this and ensure comfortable living conditions, sooner or later you need to think about warming your home. Only in this case can it be called its “fortress”.

Content

- Market range of thermal insulation materials

- Mineral wool: pros and cons

- Technical properties of glass wool

- Characteristics of cellulose insulation

- Advantages of expanded polystyrene (polystyrene)

- Extruded Styrofoam

- Durable insulation fiberboard

- Environmentally friendly cork materials

- Liquid ceramic insulation

- Liquid foam insulation

Market range of thermal insulation materials

In the modern building materials market, different types are presented insulation for walls. Before you begin to perform these works, you need to decide which insulation is better for the walls, and which – for the floor, the better insulate the balcony, and what is most suitable for living quarters. The right choice of insulation will provide heat in the winter and cool in the summer. This is achieved by reducing heat loss and eliminating drafts. Also in a properly insulated room there will be no dampness and mold, and the microclimate will be healthy. If you want to buy insulation for walls, then remember about such properties that it must correspond to:

- low thermal conductivity;

- soundproofing;

- fire resistance;

- environmental Safety;

- durability;

- water tightness;

- breathability;

- biostability.

When choosing a heater for walls inside or a heater for walls outside, it is worth considering what material the house is built from, how many floors in it, in what climatic zone you live.

So, insulation for the walls of a frame house and insulation for the walls of a wooden house (interventional) are not the same thing. In the first case, foam, mineral wool, glass wool, penoizol are suitable, in the second – ordinary tow, jute, linen felt.

Materials for wall insulation are organic and inorganic. The first group includes cellulose fiber, wood, rubber, cork, felt, moss, jute or tow. Fibrous (glass wool, mineral wool) or cellular (polystyrene foam, polyurethane foam, foam insulation, etc.) heaters, liquid ceramics are inorganic materials. Organic are more environmentally friendly, but they are not as functional and durable as polystyrene foam and polyurethane foam that are not susceptible to fungi and mold. Development and testing in the industry continues and new types of insulation for walls appear. So, liquid insulation for walls is gaining increasing popularity. Let’s look at the difference between different types of materials for wall insulation, their advantages and disadvantages.

Mineral wool: pros and cons

Mineral wool wall insulation with the construction of a frame made of metal profiles

Mineral wool is one of the most common fibrous thermal insulation materials. Mineral wool is produced by heat treatment and pressing metallurgical slag or basalt. The fibrous structure traps air in itself, thereby forming a barrier to the penetration of cold and heat loss. Mineral wool happens in the form of plates and a continuous cloth in rolls. It is used to warm rooms both inside and outside..

The thermal insulation properties of the material are ensured due to its low thermal conductivity. The advantage of this material is its breathability, durability, soundproofing properties, fire resistance, environmental friendliness.

Installation of such insulation is a rather troublesome process. On the one hand, the plates tolerate deformation well, on the other hand, it is necessary to use separate protective equipment to ensure safety.

The thickness of the material when used indoors reduces the existing space, which is undoubtedly a minus. Water permeability of mineral wool can lead to the fact that over time it gets wet from condensation, mold and fungus appear in it. This will lead to a decrease in thermal conductivity. To prevent this from happening, the material must be additionally waterproofed.

Technical properties of glass wool

Morally obsolete glass wool for warming walls of residential premises is now used extremely rarely

Glass wool is also a fibrous insulation, the most tested of all, since it has been used for insulation for a very long time. Glass wool is formed by melting sand, soda, dolomites, limestones, borax or glass wastes. They release it in plates and rolls, and for transportation.

Thin, sharp and brittle glass wool fibers are dangerous both in direct contact and when inhaling air with glass wool fragments. Therefore, using it when warming, it is important to provide yourself with glasses, a respirator, mittens. The manufacturers of this material claim that modern types of glass wool are safe for humans..

Glass wool does not burn. It has good heat and sound insulation properties. It can be used for insulation of all types of roofs, internal partitions and external walls. It is cheaper than most heaters, but it shrinks more and crumbles..

Characteristics of cellulose insulation

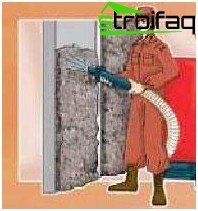

Cellulose can insulate the walls, both externally and internally.

This is one of the newest materials for insulation, it has thermal insulation properties, environmental friendliness, and functionality. Such a heater is made from the remains of pulp production. It is used both for external warming and for warming apartments inside – it is blown under drywall, magnesite boards or other materials..

Cellulose insulation is breathable, which is its positive side. Worse, it is water-permeable, susceptible to infection by fungus and mold, and is fireproof. To get rid of such disadvantages, antiseptics are added to the cellulose base to increase bio-stability and flame retardants to reduce flammability.

Advantages of expanded polystyrene (polystyrene)

The wall insulated with foam will significantly reduce heat loss.

Expanded polystyrene is produced by foaming polystyrene at high temperatures. This is a white rustling material, which is characterized by water and air impermeability, noise and heat insulation properties, light weight, ease of installation. He is not afraid of bacteria, fungi and mold, he is not afraid of bad weather conditions. Only 8 cm of expanded polystyrene can replace 1.7 m of a brick wall, 25 cm of a wooden wall or 9 cm of mineral wool.

Expanded polystyrene is the best insulation for walls. Release it in slabs that and. used for insulation of both internal walls, balconies, attics, and facades of houses. Expanded polystyrene due to its strength is not prone to sagging. This is one of the cheapest materials for wall insulation..

Extruded Styrofoam

In order to obtain such a material, polystyrene granules melt at high temperature, then the material is extruded from the extruder and foams. It turns out even more durable, durable, air- and waterproof than polystyrene. The material is in good contact with different wall coverings (plaster, concrete, brick). It is completely incompatible with resins and organic solvents..

Durable insulation fiberboard

The walls are insulated with fiberboard from the inside, the installation of plates will require the installation of a waterproofing layer and plaster

Fibrolite is obtained after the wood chips are dried and compressed by mixing them with a binder. They may be Portland cement or magnesia salts. The boards thus obtained are made of natural material, and the protective layer prevents biological effects (fungus, mold, insects) and water resistance. In order for it to retain its thermal insulation properties for longer, its additional waterproofing will be required. If the humidity exceeds 35%, then the material will sooner or later begin to deteriorate. The durability of the material will be enhanced by its additional plastering. Fiberboard is used for insulation of internal walls, partitions and ceilings. It is easy to handle and install. It is convenient to machine and mount because of its durability..

Environmentally friendly cork materials

Cork insulation for walls – an expensive, but the most long-term option

Cork panels are one of the most environmentally friendly materials for insulation. The material consists of the smallest cells (40 million per 1 cubic cm). Thus, the material has both strength and breathability, and the necessary (low) thermal conductivity.

Material for insulation is produced by granulating the raw material, heating it to 400 ° C and pressing it into blocks. Their thickness can be 10-320 mm.

Such cork panels are lightweight, resistant to mechanical pressure, and do not shrink. The material is very durable and functional. He also insulates the room. And its appearance allows you to use it even for decoration. Thus, it is possible to provide thermal insulation, and not to hide the cork behind the frames and drywall.

The cork also has bioactivity: rot, mold and parasites are not afraid of it. When ignited, does not emit harmful substances. But it is not cheap. This is one of the most expensive heaters..

Liquid ceramic insulation

Wall insulated on the outside with liquid ceramic insulation

Hot insulation for walls becomes relevant for room insulation. This is a new generation tool. They can insulate both internal and external parts of the room. Even in the most inaccessible places, liquid ceramics will help get rid of drafts and heat loss. The paste-like suspension consists of closed spheres; it is applied to a previously cleaned brick, concrete, wooden, metal, cardboard or plastic surface. Material color – gray or white.

At the same time, ceramic insulation is easy to apply, it is safe, does not burn, does not reduce the size of the room. Such a heater is still air and waterproof. After it dries, an elastic coating forms on the wall. Thin brick walls need to be processed at least 5-6 times. This material, although not cheap (its consumption per layer is -1 flax 4 square meters), but it will last a very long time. You will have to forget about insulation for a quarter of a century. So the manufacturers promise.

Liquid foam insulation

Another option for liquid insulation is filling foam, which is called penoizol. It is poured from hoses between the walls, into the cracks, the formwork during the construction process. And this option of insulation is almost 2 times cheaper than all the others. But he observes the main indicators that are important for heaters. It is resistant to bioorganisms, breathable, poorly burned, durable. Its thermal insulation properties are 8% better than polyfoam, and 12% better than glass wool. But its service life is up to 50 years.

A huge selection of heaters for walls sometimes puzzles those who want to live in warmth. Some prefer old and proven glass wool, not trusting new materials, others use only advanced technologies. But it is important, knowing the useful properties of all materials, to use them skillfully combining. Insulate walls with polystyrene or mineral wool, pour penoizol into hard-to-reach places, and treat a small area under the windowsill with liquid ceramics.