We choose an interventional heater

To build a wooden house from a bar, you need to carefully calculate and select high-quality material. Indeed, it depends on our choice how strong and warm it will turn out. The beam itself should be smooth and whole, without cracks. The thickness of the beam must be selected, taking into account both the climatic conditions of the terrain and the length of stay in the house. If you are going to use the house only for summer holidays, then you can take a medium-thick timber. But the house in which you will live permanently is better to build from a thicker timber. Another important factor for ensuring the preservation of heat in the house is the interventional heater. That’s about how to choose it correctly, we will tell.

Content

- The specifics of timber buildings

- Insulation Quality Requirements

- Range of insulation materials

- Artificial materials

- The use of natural materials

Interventional jute insulation

The specifics of timber buildings

A quality wooden house has some features that traditional stone or brick houses do not have. These features include:

- high thermal insulation properties of wood, thanks to which it is not necessary to make a thick wall

- the ability of a tree to moisture exchange is the absorption of moisture upon saturation with it and the release of moisture in the dry period, which ensures optimal humidity in the house at any temperature and prevents condensation on the surface of the walls, which means it protects against fungus and mold

- the presence of wood pores that allow air to circulate freely enough – this ensures natural ventilation of the premises

- the ability to redistribute heat throughout the entire massif of wood, it is this quality that makes it possible to quickly and easily melt a house

To insulate a wooden house, an insulating material is required with the ability to freely pass steam and moisture

But all these advantages are lost if the insulation is improperly selected..

If the material of the insulation does not allow the wall of the beam to be a single whole and prevents the manifestation of the precious properties of wood, then the house will never become as warm and reliable as we would like.

Insulation Quality Requirements

The material used as insulation provides the house with reliable protection from the cold. So, you need to choose it, focusing on the following characteristics:

- the density of the material and its elasticity – the insulation must tightly close the cracks between the crowns, not only immediately after the erection of the walls, but also after the shrinkage of the house

- low thermal conductivity, close to the thermal conductivity of the beam and providing minimal heat loss through the space between the crowns of the house

- the ability to absorb and release moisture, most appropriate to the same ability of wood to maintain optimal humidity in the house and protect the walls from decay

- resistance to external environmental influences – this includes opposition to both atmospheric influences (precipitation and air temperature), and the actions of birds who love to pull the caulk to their nests, and insects seeking to make themselves comfortable housing in the walls of the house

- longevity – the ability to maintain its beneficial properties for a long time, ideally – all the time of operation at home

- safety for humans – the absence of harmful impurities and substances that cause allergic reactions

- antibacterial properties – resistance to the development of microorganisms that can cause rotting or disease

Having carefully analyzed all the qualities necessary for a good insulation, you can proceed to a reasonable choice of material.

Range of insulation materials

Now in the market of modern building materials you can find many different insulation materials. They can be divided into two large groups – artificial and natural.

Artificial materials

- synthetic and mineral based heaters – glass wool, staple glass fiber, basalt raw materials, mineral wool

- closed and open cell insulation – expanded polystyrene, foamed polyethylene, polyurethane foam, silicone and acrylic sealants, polyurethane foams, foam rubber

All these materials have proven themselves perfectly when warming walls, roofs, ceilings and floors in brick houses or concrete panels. But they are not suitable for thermal insulation of walls made of wood. Even materials such as mineral wool or foam rubber become too dense when compressed and completely block the circulation of air and moisture. This can lead to undesirable consequences. In the case of materials that absorb moisture well, seams with such insulation are frozen at low temperatures. If the insulation is moisture-proof, then the steam condenses at the junction of the wood and the sealant, causing rotting and destruction of the walls.

One of the negative examples of the use of such materials may be the so-called “warm seam”. The technology of laying seams, similar to a sandwich, uses a self-adhesive tape based on foam, impregnated with a composition that increases the volume of the material in contact with air. Manufacturers believe that such a property will fill all the voids and carefully close the gaps. This tape is placed on the horizontal surface of the crown. Then, the seams on the outside or inside (and it is possible on both sides) are caulked with extruded polyethylene made in the form of a cord of various thicknesses. And finally, on top of all this, an acrylic sealant is applied with a mounting gun. It would seem that the cracks are closed tightly, the heat is safely stored. But what will happen behind the sealant crust in the seams themselves? Outside, neither air nor water can penetrate, but the foam will quickly pick up moisture from the tree, but simply can not dry out. And damp seam gives us all the troubles listed above.

The use of natural materials

Some “experts” suggest using cotton or wool batting or felt as insulation. Reasoning on the topic: “These materials retain heat well, which means that they can also be used for laying cracks”, unfortunately, are not entirely correct and clearly not suitable for building wooden walls. After all, both wool and cotton gain moisture too much, do not dry well, especially when compressed, and are very attractive to insects. So with their help it is better to warm clothes and shoes, and not a house.

To ensure the full manifestation of the positive qualities of wood, for insulation it is worth choosing natural materials that have long been used in wooden architecture. So, what natural heaters are most suitable for the construction of wooden houses?

- tow (from flax, hemp or jute)

- long-fiber moss

- jute non-woven (felt) tape

Any of these materials is perfect for insulating inter-crown seams. They have low thermal conductivity, bactericidal properties, and the ability to absorb and give off moisture. But each of them has its own characteristics, which can be attributed to both advantages and disadvantages..

The best interventional heaters

Linen tow for insulation

Tow is made from coarse short fiber. It is a departure from the primary processing of plants. The composition of flax includes: cellulose – 76-80, lignin – 2-5, pectin – 3, wax 2-3. Durable, hygroscopic, elastic material. It is used for sealing plumbing joints and for warming interventional cracks. Its disadvantage is the difficulty in laying. After all, with a flat surface of the beam, the same uniform distribution of insulation is required, which is quite difficult to implement using tow. And double caulking significantly slows down the construction of the house. A neatly laid tow is also pulled apart by birds, which is why you need to constantly monitor the quality of the caulk.

This kind of tow is used to warm interventional seams

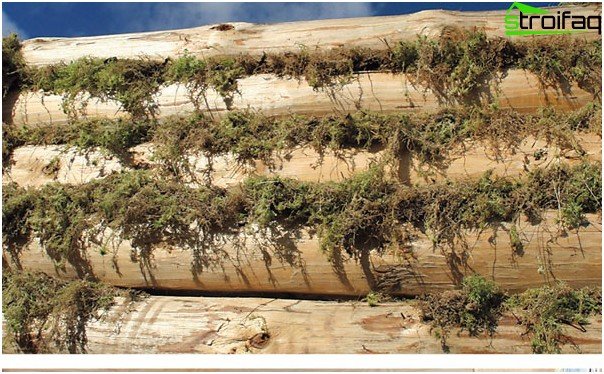

Slit moss

For caulking holes in the log house most often used cuckoo flax, red moss or sphagnum. All these types of moss have long been used for insulation in the construction of wooden houses. Now it is mainly used for baths from logs or beams. Moss has good antifungal properties needed for wooden buildings by moisture absorption and recoil, is not susceptible to decay, and also provides good natural ventilation..

Laying the moss on the beam, you should leave a long (about 10 cm) fringe, which then must be pushed into the crevices with a special caulk. This, of course, makes the process of erecting a log house slower. Among the shortcomings of the material itself, it is worth mentioning a large shrinkage and brittleness, because of which caulking of the cracks must be constantly updated. In addition, he has the same problem as tow – the difficulty of uniform styling.

The moss laid between the crowns is too appetizing bait for birds, because of which the insulation will have to be periodically restored

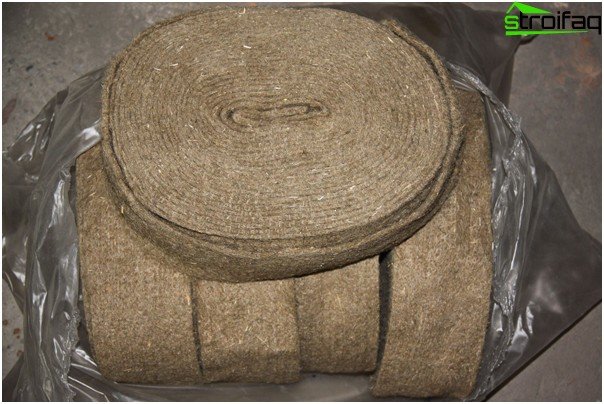

Popular jute insulation

One of the most popular now is jute interventional insulation. Many of its qualities are ideal for warming wooden houses. Builders are especially attracted to modern material – felt jute tape. The jute itself is most optimal in its properties: it contains lignin (12.7), which is responsible for fiber stiffness, and pectin (0.2) with wax (0.3-0.4), which give jute fibers the necessary flexibility and elasticity, as well as preventing it from drying out.

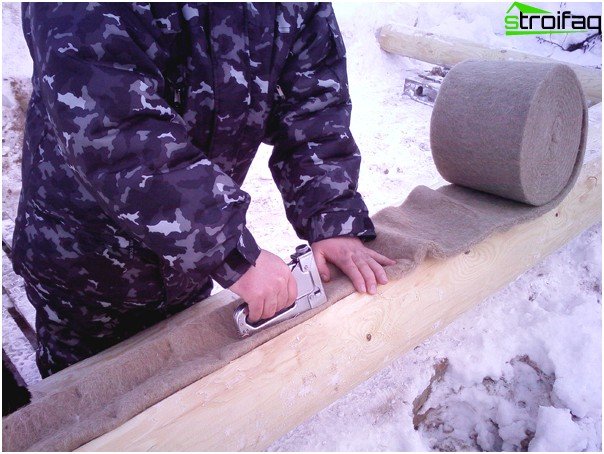

We lay the jute interventional heater additionally fixed with a construction stapler

We list the advantages of such a tape:

- ease of laying – you just need to roll out a roll of tape along the crown of the log house

- uniformity – the uniformity of the tape allows the crowns to fit snugly together

- density – does not stick out of cracks, birds cannot pull it apart, does not wrap on a drill a drill

- strength and durability – felted fibers retain their properties for a long time

- hygroscopicity – good moisture absorption and quick drying

- profitability – with jute insulation in the form of a tape there is no need to make double caulking

- environmental friendliness – a natural material without harmful impurities and related to wood

In addition, jute felt tape has the following characteristics:

- density not lower than 700 grams per square meter

- tape length – 25 m per roll

- tape width varies from 2 cm to 1 m

- the thickness of the tape in the free state is 4-12 mm, in the compressed state it decreases one and a half to two times.

As you can see, the properties of jute tape are most consistent with those qualities that a good insulation should have.

Having carefully examined all types of insulation offered for construction, we found materials that are most suitable for houses made of timber. All the qualities necessary for revealing the useful features of wooden buildings turned out to be collected in a roll of jute tape. Due to the fact that the tape is available in various widths and thicknesses, everyone will be able to choose a heater that is ideal for him.