How to insulate a balcony with your own hands

People living in apartments by any means seek to expand the space. Achieving this goal is possible by warming the balcony and connecting it to the living rooms. In addition, the implementation of such work can significantly reduce heat loss. The task of the events is how to insulate the balcony with the greatest efficiency and provide high-quality thermal insulation of the room.

Content

- Materials for thermal insulation of the balcony

- How to insulate a balcony with your own hands: stages

There is a huge selection of ideas available for implementation on the balcony (study, winter garden, relaxation room), but warming is a must for any idea. A simple glazing device provides partial protection against the cold, unable to give comfort when on the balcony. Warming should be carried out from the outside, containing the enclosing structure. In the process of performing work, the balcony fence moves to the zone of positive temperatures, excess moisture freely penetrates through the insulation layer and is discharged to the outside. A prefabricated multilayer construction ensures optimum thermal insulation performance..

As practice shows, in multi-storey buildings there is no possibility of external insulation, so the only possible way out in this situation is to carry out work from the inside. With this method, small puddles of water may appear in the cold season. You can avoid problems with the installation of an additional vapor barrier layer. The “dew point” is located inside the room, because through a layer of thermal insulation air flows from the room to the cold balcony structures, turning into drops of water. With external insulation, the “dew point” is located outside, which prevents the formation of condensate. The latter method is recommended for use..

Materials for thermal insulation of the balcony

To determine how to properly insulate the balcony, you should first select the materials used. The modern market offers a wide range of building materials necessary for insulation of premises. The most common are: foamed polyethylene, extruded polystyrene foam, mineral wool.

Foamed polyethylene is one of the modern types of insulation, characterized by unique characteristics. The structure of this material contains foil. When using foamed polyethylene, reliable protection against cold and prevention of air condensation is ensured..

Expanded polystyrene perfectly retains heat, having better thermal insulation properties compared to other materials. It is convenient in transportation and use, does not break, is easily cut with a knife. The rigidity of polystyrene foam allows you to use it as a base for screed. The sheet thickness is 5 centimeters, allowing you to save usable area.

Mineral wool has a higher cost, but is able to last a long time. Very often the use of such material is considered inappropriate.

How to insulate a balcony with your own hands: stages

You should consider a phased scheme of actions that allows you to understand how to warm the balcony yourself:

- The first step is to prepare the balcony for glazing;

- The second stage is direct glazing;

- The third stage is warming;

- The fourth stage – the final decoration of the balcony.

Very often the walls of the balcony are concrete slabs that do not differ in particular thickness, and an iron grate acts as a parapet. Of course, under such conditions it is impossible to achieve a comfortable indoor microclimate. You can’t do without additional work aimed at creating high-quality thermal insulation, since it is necessary to insulate the balcony from the inside. First, lay the walls of the balcony with lightweight ceramic bricks or foam block slabs. Such a masonry will be draft, so even a person with no experience will cope with the work at this stage.

Glazing turns a balcony into a loggia protected from atmospheric negativity

After preparing the walls of the balcony, you can start glazing it. PVC windows have become widespread, but recently, wooden structures have become increasingly popular. They are not inferior in quality to metal-plastic analogues, provided that the correct processing is observed, which consists in applying an antiseptic, coating the surface with paint in several layers and a number of other measures.

The service life of high-quality structures made of natural materials is comparable to the period for PVC windows. After installing the double-glazed windows, there are almost always gaps that need to be removed. To do this, use mounting foam, which is quite convenient, easy to use and has the necessary characteristics. Sealing allows to some extent to reduce heat loss. We can say that at the first stage of warming, the balcony is transformed into a glazed loggia.

Glazing of the balcony only partially solves the problem of thermal insulation

It is important not to make a common mistake, which is the result of hastily done work. Very often double-glazed windows are put in, hastily closed up and a heating radiator is installed in the room or a “warm floor” is arranged, but these measures are not enough for good insulation. With this approach to performing work, the heat will go out almost unhindered, and ensuring the optimal temperature will be fraught with considerable difficulties. The application of a professional approach to warming the balcony will allow you to perform quality work, significantly reduce the level of heat loss from the apartment.

Important! Building regulations prohibit the use of central heating to heat a balcony.

At the next stage, all structural components of the balcony are insulated – walls, floor, ceiling and parapet. When choosing a heat-insulating material, it is necessary to take into account the following properties: thermal conductivity, material thickness. The use of thinner material with lower thermal conductivity avoids a significant reduction in usable space. There are various methods of thermal insulation.

The standard balcony has a slight slope of the floor towards the street. Therefore, before laying the insulation, it is necessary to level the surface using self-leveling cement-sand mixtures. If necessary, raise the floor, use expanded clay filling of two fractions to carefully fill the voids. The use of fine and coarse fractions avoids subsidence of the coating. A layer of waterproofing is laid on a layer of expanded clay.

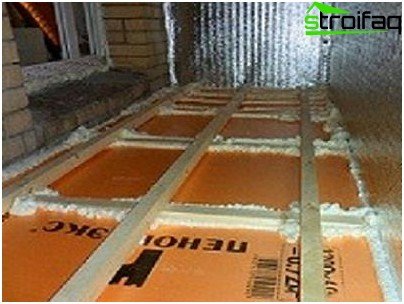

Let us consider in more detail the insulation of the balcony floor using extruded polystyrene foam. At the initial stage, foil penofol is laid with the foil facing up to reflect heat and provide vapor barrier. Then the 40x40mm wood bars are fixed in level every 50 cm. In the cells obtained between the bars, it is necessary to place polystyrene foam sheets, and fill the remaining slots after installation with foam.

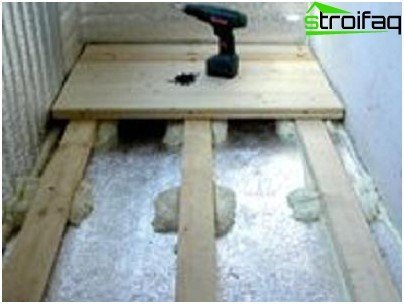

Floor insulation on the balcony: wooden logs are laid on top of the penofol

Perpendicular to the first layer, the second layer of wooden blocks is fixed. Using this technology allows you to create an air cushion, which will further improve thermal insulation and ensure the strength of the base. Moisture-resistant plywood is laid on the top layer, on which it is possible to cover the floor with linoleum, tile or laminate.

The design with lags allows you to create a heat-insulating air cushion

The description of the main stages of repair work allows you to understand how to insulate the floor on the balcony, taking into account the recommendations of professionals.

There are two ways to fix polystyrene plates: with glue or dowels.

- When using glue, it is important to ensure its compatibility with the material. The glue is applied to the plate with a spatula, stepping back from the edge a few centimeters so that the excess does not fall on the joints of the plates. Strips with a width of about 5 cm are sufficient for good adhesion to the surface, an additional 5-10 glue points are made over the remaining area.

- When using the second mounting option, it is necessary to purchase special dowels, which have a large hat. In general, for attaching 1 sq.m. insulation need to use 5-7 mounting points.

It should be noted that in practice using a combination of two methods of fastening. First, with the help of an adhesive composition, the sheets of expanded polystyrene are glued to the surface, and then fixed with dowels using screws, plastic nails.

Important! The joints of the insulation with the wall should be glued with vapor barrier tape so that fungus and mold do not develop.

It is important to consider that it is not advisable to use mineral wool as a heater. When applying this thermal insulation material, it is necessary to carefully arrange the vapor barrier layer. In addition, mineral wool is susceptible to moisture and shrinks over time..

By analogy with the floor, the side walls and the ceiling of the balcony are insulated. Performing work at this stage is less difficult. Polystyrene boards are glued to the walls and ceiling using cold bitumen mastic, distributed evenly over 25% of the area of the board. This method allows you to save the useful area of the balcony.

The final stage of balcony insulation is the implementation of the interior decoration. As wall covering material, a lining, moisture-proof drywall or wood panels are often used. Before starting their installation, you should create a crate on which the finishing material will be attached, as well as lay the wiring. When installing the crate of metal modules, suspensions must be installed for them before the start of laying the heat-insulating material.

Insulation of the walls of the balcony from the inside: design for fixing heat-insulating material and decoration

When insulating the ceiling, you can use a suspended ceiling instead of a drywall, which will allow you to hide all the wiring.

It should be borne in mind that the insulating layer performs the function of maintaining heat, but not its production. It is important to ensure that a heat source is available in order to maintain a comfortable temperature on the balcony. Such a device can be a heater, underfloor heating, air conditioning and other similar equipment.

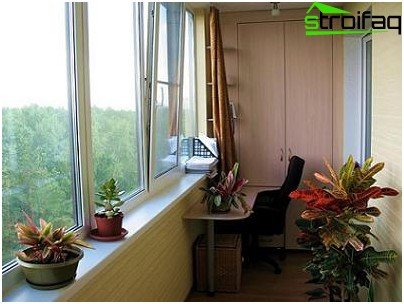

Ready-made functional solution for the balcony

In conclusion, it should be noted that high-quality insulation of the balcony, of course, requires significant financial and labor costs. But the result will please more than one year. The phased implementation of the work will provide a reduction in heat loss in the apartment, as well as comfortable living throughout the whole year. Using a set of warming measures, you can turn a cold balcony into a warm and healthy room.