How to insulate the floor in a wooden private house

The problem of heat loss is typical for almost all private houses and cottages. The main part of it goes through the floor, because it is this structural element that is closest to the ground. Naturally, the owners of such real estate are concerned about this fact and are trying to find all kinds of ways to solve the problem. How to insulate the floor in a wooden house? What materials exist for this? And how to carry out such work yourself? You will find answers to these questions in this article..

Content

- Materials for floor insulation in a wooden house

- Mineral wool for floor insulation

- Expanded polystyrene: scope, specificity

Materials for floor insulation in a wooden house

Mineral wool for floor insulation

This material for thermal insulation has a number of positive characteristics that allow you to confidently talk about it as the best.

- Mineral wool has high sound and thermal insulation.

- It is resistant to moisture and fire..

- Perfectly retains its qualities for a long time.

- It tolerates strong mechanical stress..

- Environmentally friendly.

- Inexpensive.

- High chemical resistance.

Mineral wool is produced in the form of solid slabs or a flexible mat. Both the one and the other type are well cut, which is important when carrying out insulation work.

Important: when laying mineral wool, make sure that its foil side is directed inside the room, that is, it is on top.

Types of mineral wool

Expanded polystyrene: scope, specificity

Expanded polystyrene is most often used for basement insulation, basements, floors in wooden houses, as well as for thermal insulation of floors with heating systems.

This material has the following properties:

- durability

- environmental friendliness

- high rates of biological resistance to various kinds of microorganisms

- high thermal insulation

- shape and volume stability

- strength

- minimum degree of water absorption

- the convenience of use

- soundproof.

Perhaps the only disadvantage of polystyrene foam is its high cost compared to mineral wool.

Polystyrene foam boards are used for insulation of basements, socles, communication systems of wooden houses

Of course, these two types of thermal insulation materials can be replaced with others, for example, expanded clay or polystyrene, however, it is polystyrene foam and mineral wool that are recommended for warming wooden floors and they give the most noticeable effect.

Double floor system in a wooden house

When building a wooden house, you need to immediately make sure that the floors in it are warm. Many experts recommend using the “double sex” method.

From the name itself it is clear that you will have to make flooring from boards twice, only these boards will be different.

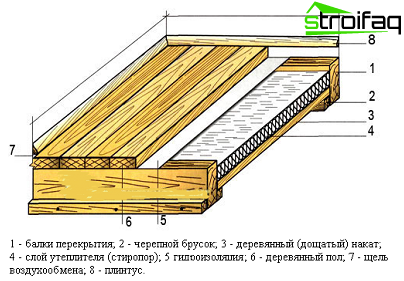

The scheme of warming a wooden floor

The rough floor is made of unpolished boards, which must be carefully adjusted to each other so that there are no gaps. If it is not possible to obtain an ideal surface, you can close the cracks with mounting foam or cover them with plaster. A layer of roofing material is laid on top of the boards, which will protect the wooden floors from the growth of fungi and mold. Then a thin layer of sand is poured (its height should be only 3-5 centimeters) and level it.

So that the sand is not exposed to moisture, it is covered with a plastic film. We select its thickness by eye, but it is best to take the thickest that is in the store. The film needs to be fixed with nails or a construction stapler. Instead of a film, you can use a special material – penofol, which is a flexible foil polyethylene. This vapor insulator not only retains heat in the house, but also does not allow moisture to pass through. He spreads a foil inside the room.

Now you can start laying the heat-insulating material, which must first be cut into pieces of the desired size. Choose the thickness of the insulation yourself, based on the conditions of the area in which you live. So, for Siberia, the thickness of the insulating material should be at least 200 mm, and in Finland, after severe frosts in 2009-2010, this standard was increased as much as 400 mm. So count!

Chipboard plates are laid on top of the insulation, on which the final floor will be laid later.

Laying mineral wool on the rough floor

Floor insulation in a wooden house with polystyrene foam chips

Hanging insulation system

This technique is in many ways similar to the double floor system, with the only difference being that instead of the subfloor, a fishing net is used and you do not have to remove the finishing floor.

You need to take the thickest and strongest fishing line so that it can support the weight of the heat insulator. Insulation works are carried out from the basement.

Using nails, you need to fix the fishing line on the beams. Stretch it so that the size of the received cells is no more than 20 cm, but in general, the smaller the size of the cell, the more reliable the insulation will hold. The space thus obtained between the floor and the net is filled with mineral wool or polystyrene foam.

The disadvantage of this technique is the fact that over time the fishing line will stretch and the insulating layer will sag, and its contact with the inside of the floor will not be so close.

But there is a plus – you significantly save on building materials, because you do not have to buy boards for the subfloor.

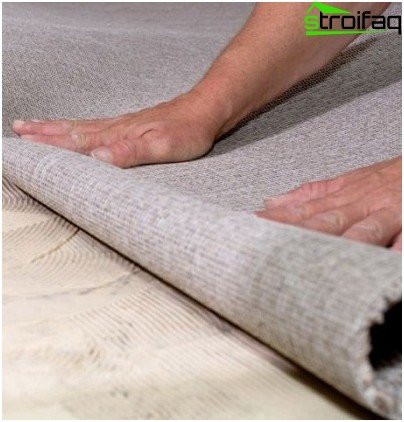

Warming of a wooden floor with carpet

Another method floor insulation in a private house without opening it – insulation with carpet. For these purposes, use a carpet – a material that in its characteristics is very similar to ordinary carpets.

The carpet is laid around the entire perimeter of the room – it is this moment that distinguishes it from carpets.

You can, of course, just cover the floor with this coating and “sleep soundly.” That’s just your dream is unlikely to be so peaceful. The wooden floor is not similar to the concrete one in that it has gaps through which cold air from the basement enters the house. No carpet can protect you and your loved ones from this fresh draft.

To avoid such oversights, it is recommended that you first lay a special heat-insulating substrate, which is sold in many construction stores, and after that lay the carpet.

The carpet itself can be fixed with a plinth, or you can buy glue that will securely fix the carpet in place.

Carpeting

Instead of carpet, you can use linoleum on a special basis from jute or felt. Such a warm substrate will keep the floor warm and the atmosphere in the house cozy and comfortable..

Modern technology at the service of man

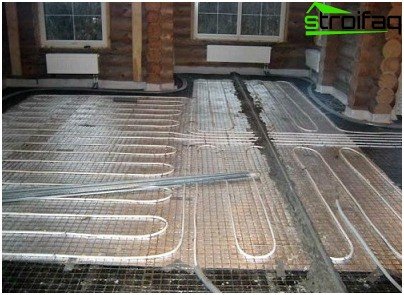

With the development of progress, a mass of alternative options floor insulation. Now you can achieve an excellent effect with the help of special systems called “underfloor heating”. Insulating the floor in a private house has become easy!

Such a system is very easy to install and can be installed directly on the logs or subfloor. It is absolutely safe for wood, so you can not be afraid of accidental fire and feel free to warm your house in this way.

There are two types of such systems:

- rack type underfloor heating system

- modular underfloor heating system.

Both of these systems are water-based, that is, they heat the wooden floor with water, which constantly circulates through pipes, which are the main structural element.

The system of modular type uses module elements that are made of chipboard with a thickness of 22 mm. These sheets have small channels for tubes and plates along which water moves.

In the rack-and-pinion system, tubes and plates are placed between the strips of chipboard having a minimum thickness of 28 mm (the thickness may be more). For tubes there are special grooves with a width of 20 mm. Thus, the whole system is rigidly fixed and you do not have to worry about the plates moving away from vibration.

Both systems are mounted the same way:

- We remove the old floor, including the rough one, if, of course, you had it.

- A thick block is nailed around the entire perimeter of the room, which will act as a support for the future floor.

- We install logs with a step width of 0.6 meters.

- We are laying the underfloor heating system. During its installation, the wooden base, on which all tubes and plates are fixed, acts as a rough floor, which allows to slightly reduce the item of expenses due to savings on the purchase of boards.

- For a more snug fit of the rough floor to the floor, experts recommend laying between them a layer of polyethylene, which will serve as a kind of “pillow”.

- Now you can mount any floor covering – laminate, parquet or just lay boards.

There is one important nuance: if you plan to put ceramic or stone tiles, linoleum or carpet on a wooden system of underfloor heating, then before you begin to perform these works, you must make an overlap of gypsum fiber plate. Such a shield is needed for:

- protect the coating from possible deformation due to heat;

- uniform distribution of load on the rough floor;

- uniform heat distribution from the heating elements to the floor covering.

Of course, such a pleasure costs decent money, but then you get the perfect floor, which will be warm when you want it..

Installation of the “warm floor” system

Drastic measures to warm the floor in a wooden house

If none of the methods suits you or does not bring the desired result, one thing remains – to insulate the base. Such work will take you a lot of time and effort, but your floor will definitely become warmer.

So, for starters, you will have to dig a trench around the perimeter of the house with a depth of about 0.5-0.7 meters and a width of about 40-50 cm. To effectively protect the insulating material from rodents, a claydite-concrete screed is made at the bottom of the trench.

Now you can install insulation sheets. It can be polystyrene foam or expanded polystyrene. But they are not enough to establish, it is also necessary that they stay in place. To do this, use mastic or special glue, which is pointwise distributed over all surfaces of the canvas. All cracks and joints between the sheets of insulation are foamed with mounting foam.

Next, we apply glue to the polystyrene foam (it will be more reliable), install formwork panels around the entire perimeter of the house and fill the resulting space with expanded clay concrete.

Thus, the insulation is completely isolated from the environment, rodents and moisture, and your floor from cold and frost.

Now you know how to insulate the floor in the house, but do not rush to immediately throw to the tools. Weigh the pros and cons, calculate the expense items, consider all the nuances, and only after that you can start work.