Expanded polystyrene: types, characteristics of insulation

The goal of developers and manufacturers of advanced insulating materials is to create a product that maximally meets the technical, construction, hygiene and operational requirements. Until ideals are created, each of the heaters has its own priorities and negative qualities. As well as polystyrene foam, actively used in the construction of low-rise private buildings, used in industrial construction, in facade decoration. This heat-insulating material has undeniable advantages and a number of disadvantages that you need to know for the owner of a residential property or a house under construction, who decided to choose this type of insulation.

Content

- Scope, characteristics

- Technical and operational benefits

- Technological advantages of plates

- PPS Disadvantages of foamed insulation

Scope, characteristics

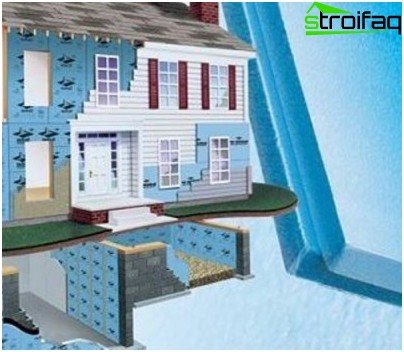

The field of use of lightweight effective heat-insulating material is regulated by GOST 15588-86. Based on the regulatory requirements listed in the document, the use of expanded polystyrene is recommended for the implementation of the middle layer of the supporting external walls. This type of insulation is equipped with ventilated facades, attic floors, and occasionally flat roof structures based on a non-combustible base. Most often they use material for floor insulation, especially when installing a warm floor with a screed. It is indispensable for the arrangement and insulation of basements, isolation of foundations and socles located in the zone of constant or periodic exposure to groundwater.

Expanded polystyrene is a universal insulation used to increase the thermal performance of almost all elements of the building

Technical and operational benefits

- Polystyrene foam, which has been abbreviated as PPP in our country, differs in strength and rigidity from mineral wool plates, fibrous, brittle hard and bulk materials. It holds a rather impressive load, the construction characteristics are not affected by the construction drawdown.

- The insulation has the highest thermal performance, justified by its unique structure and composition, including 98% of the air mass or inert gas. Thanks to its excellent insulation performance, the material helps to reduce costs in the heating season by almost 30%.

- PPP is not hygroscopic, which is why it is often chosen to equip underground structures that are subject to constant exposure to soil moisture. Plastic cells are not accessible for water penetration, moisture can leak out only through the intermediate channels between the cells.

- The material has virtually no temperature restrictions for the construction of residential and utility buildings; it is used in almost all domestic regions.

- Polystyrene foam is frost-resistant, can withstand from 80 to 120 cycles of freezing and subsequent thawing without breaking structural bonds. Manufacturers indicate these data in the technical description of the material. Based on the research, the calculation of guaranteed operational terms is performed. That is, the positive results of 120 cycles indicate a 60-year period of perfect operation.

- Expanded polystyrene foam enhances sound insulation.

- Expanded polystyrene plates are inert to most chemically aggressive environments, such as saline solutions, alcohols and alcohol dyes, acids, animal and vegetable oils. Without damage and structural changes, it works in contact with concrete, aerated concrete, bleach, any type of plaster, paint.

- The insulation is not susceptible to decay and other biological effects..

- No radioactive background.

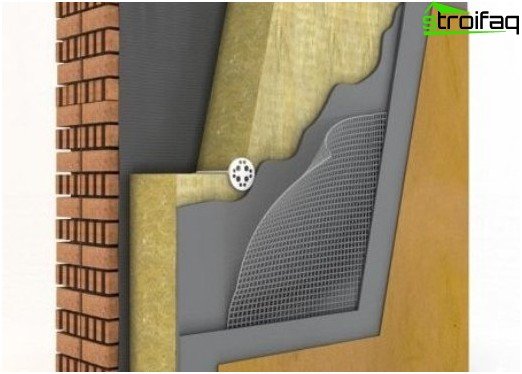

Expanded polystyrene panels as a middle element of the supporting building structure

Technological advantages of PPS plates

The advantages of its installation are based on the combination of strength with the absence of fragility and light weight of foamed polystyrene:

- A performer who does not have the skills of a builder will cope with equipping a summer house or a country house with polystyrene foam insulation.

- The faculty is easily processed, cut with a simple knife or a hand saw, with its help any structural elements of any complexity are insulated.

- Lightweight slabs will slightly increase the load of the entire building structure on the foundation, due to which reinforcement of the foundation will not be required when performing repair work or when warming the facade. It will not be necessary to build a powerful fundamental foundation for new construction.

- The power of the insulation boards together with the top layer of plaster will not significantly increase the external perimeter of the building, which means that you will not have to expand the roofing system.

- You can work with polystyrene foam without special protective equipment, it does not cause irritation, painful reactions or redness on the skin of the hands. The contractor will not have allergies, eczema, eye damage or respiratory tract.

Prepared for installation factory plates – the best choice for effective operational insulation

The disadvantages of foamed insulation

There are limitations: with the help of this insulating material it is impossible to insulate any structures made of wood. It is not suitable for arranging walls made of timber or logs, as it interferes with the natural exit of steam and excess moisture through wooden walls. With the help of expanded polystyrene, roofs with rafter wooden systems are not equipped.

The top layer of foamed polystyrene can be destroyed by direct exposure to ultraviolet rays, x-rays and high temperature. From the negative influence of the teaching staff, a layer of plaster applied to a special metal mesh always protects, sometimes the simplest painting is used. Failure may occur during storage under direct UV exposure or high temperature.

As a heater, expanded polystyrene is not recommended for indoor installation. However, the building regulations did not recommend a well type of insulation at all. Allowed the location of any type of thermal insulation material after the vapor barrier layer. That is, first vapor barrier, then insulation.

Types of building polystyrene foam

As a building heat-insulating material, two types of polystyrene foam insulation are used:

- block view (PBS) obtained by foaming styrene with additives in a special mold;

- extruded polystyrene foam produced on extrusion equipment by forcing molten polystyrene mass through a nozzle that determines the configuration and size of the product.

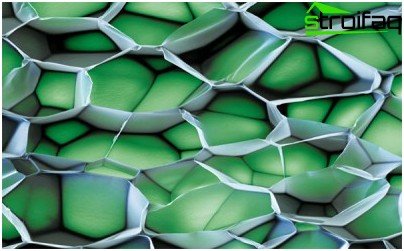

The structure of extruded polystyrene foam

Two different methods of production predetermine the difference in technical characteristics and operational properties of the final product, determined by different conditions of molecular orientation. The main advantage of the insulation obtained according to the first technology is its affordable cost, but it is inferior to extrusion products in terms of insulation. Block insulation, divided into plates after manufacture, absorbs more moisture, worse impedes the passage of heat and sound waves.

How to insulate polystyrene foam?

In the fight against the shortcomings of expanded polystyrene foam, developers modify the formula by introducing various additives. Technologies and components introduced into the insulation are strictly protected by manufacturers and are their commercial and intellectual property. The new generation of expanded polystyrene contains flame retardants that prevent burning and interfere with the rapid spread of fire. Active development is carried out in the field of increasing the long-term material, resistance to external negatives of various origins.

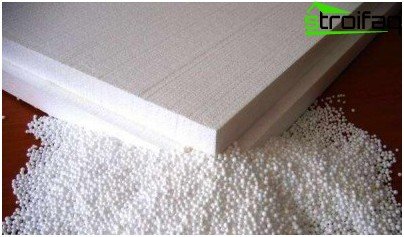

Expanded polystyrene – insulation in the form of plates with stable stiffness

Definitely, preference should be given to products with well-known brands, such as BASF, Knauf, the domestic giant Teplex, a number of well-known American companies. Their products are tested without fail, have certificates and confirmations of sanitary and hygienic safety. Most construction organizations are mistrustful of handicraft products, since the buildings they erected are subjected to state inspections.

Reality and Myths about Harm

Intensively discussed by the media, a fire in the notorious Perm club with the name “Lame Horse” brought a lot of complaints to the polystyrene insulation. Despite the fact that the product from reliable manufacturers is sold accompanied by documents confirming the safety, the entire insulation is assigned to the category of harmful products by amateurs. Of course, poor-quality expanded polystyrene can cause harm, which is associated with a violation of production technologies. The products of reputable manufacturers engaged in the production and sale of insulating materials for more than 60 years, are unreasonably criticized and discredited.

The reason for calling for the abandonment of polystyrene foam was harmful gaseous emissions, poisoning 155 people in a burning club. No one thought that the toxic combustion products emitted other materials. The toxicity of burning natural wood and decoration materials is similar to the release of polystyrene foam used to cover the club ceiling. Of poor importance was poor ventilation and violation of other safety regulations.

Foamed polystyrene insulation – a popular material for home improvement

In Europe, this thermal insulation material has been used for many decades, which in practice has confirmed the absence of harmful effects. There is no accurate data on the occurrence of hereditary changes and complex diseases that occur due to the warming of the faculty. It releases toxins only during melting and temperature readings exceeding 320 degrees Celsius. Under the operating conditions recommended by the manufacturer, negative consequences are excluded. New modifications with improved properties belong to the category of non-combustible harmless building materials evaluated according to the criteria of the ETICS system.

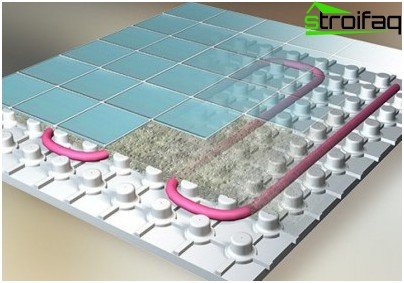

Expanded polystyrene for floor insulation

Rigidity and excellent load-bearing ability of polystyrene foam boards have justified the priorities for the use of this material for floor insulation. Convincing the use of expanded polystyrene insulation characteristics, due to which heat loss through the surface of the lower floors is minimized, noise penetration is reduced.

Special expanded polystyrene panel for installation of underfloor heating system

For the insulation of floors, mainly boards are used, the thickness of which does not exceed 50 mm. Usually they are laid on top of loose or rolled material with insulating properties, placed between the lags. Butt joints between plates must be sealed. Then make a screed with concrete or sand-cement mixture, the layer of which should be 6 cm. Instead of screed, lay sheet pile wood chips or apply both schemes in combination. Seamless screed or “dry” floor perform the function of a cushioning element. Thanks to this layer, the penetration of sound vibrations into the ceiling-floor structure is excluded.

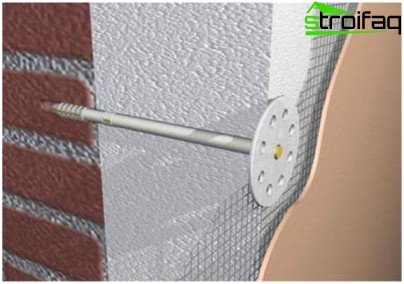

Wall insulation with PPS plates

Two technologies are used for wall insulation with polystyrene plates:

- installation of insulation elements using long nails with wide hats;

- installation of plates using special adhesives.

Fastening the front polystyrene insulation with specific large-head nails

Before applying glue to the surface of the outer wall, it should be cleaned of dirt. It is necessary to clean the material itself, and slightly wet the wall. In order to reduce the consumption of glue, it can be applied in fragments with a step of 20 cm. To process a wall of expanded clay concrete, more glue is needed than for walls made of foam concrete or brick. The plasticity of the glue allows timely elimination of flaws, correct the incorrect position of the plate. It is not necessary to glue the boards along the butt joints. While the binder material dries, it is possible to fix block or extruded polystyrene foam with boards, leaning them against the insulated surface. After the final drying of the binder material, the walls are covered with plaster, decorative panels or facing bricks.

Conclusion: to summarize

After weighing the advantages and disadvantages of PPP, you can easily decide on the choice of thermal insulation layer. This type of insulation is characterized by an excellent combination of efficiency and cost. The price of material that does not belong to the category of budget products will quickly come true in the process of operating an energy-efficient solid house.