The question of which is better – porcelain stoneware or tile, is becoming increasingly relevant today. This is not surprising, because if the tile among the finishing materials, it can be said, is a long-lived, then the porcelain tile, from the point of view of design and construction, is not just young, but still very young material. It began to be manufactured and used in the mid-70s of the last century, but in such a short time he had already managed to not only take a leading position among related materials, but also tends to displace them from their established positions. The ceramic market is developing so rapidly today that even a specialist is not so easy to navigate it, not to mention ordinary people. For example, how many people know how ceramic tiles differ from porcelain tiles? And which one is better to use for decoration or repair? Let’s try to figure it out.

Content

- What is porcelain tile?

- Composition and production process

- Unique qualities, durability

- Universality of application of the material

What is porcelain tile?

To find the answer to the question which is better – porcelain stoneware or tile, you need to learn as much as possible about this relatively young, and maybe not very familiar material for many – porcelain stoneware.

Porcelain tile is an artificial finishing material that surpasses in many ways its natural counterpart – granite.

Porcelain tile surpasses its natural counterpart in some properties – granite

Moreover, this superiority is manifested not only in its technical properties, but also in terms of design – it has a wider color gamut. He also competes with ceramic tiles. Exceptional art forms were added to such serious technical characteristics as durability, almost zero water absorption, wear and frost resistance..

Composition and production process

Porcelain tile received unique properties due to its composition and special production technology. For the manufacture of porcelain stoneware, high-quality clays (kaolin and illite) are used, to which quartz sand and feldspar are added, as well as mineral coloring pigments to give different colors. The production process takes place in two stages.

At the 1st stage, materials in special molds are pressed under a pressure of 500 kg / cm. Next, the pressed materials are fired at a temperature of 1300 ° C. Under the influence of this temperature, their structure changes at the molecular level – a high-strength glass monolith is obtained.

In fact, the production of porcelain tiles is like the formation of natural stone, with the only difference being that this process is under the control of a person, and it uses those components and technological methods that make it possible to achieve better operational properties than natural stone.

Unique qualities, durability

Porcelain tile gained its popularity in use due to a number of properties that distinguish it from many other finishing materials:

- Resistance to mechanical damage, hardness. Such plates can withstand loads of up to 450 kg.

- Abrasion resistance. The most durable of porcelain stoneware is considered matte..

- Low water absorption. Special manufacturing technology provides a very dense structure and as a result, granite absorbs only less than 0.05% of moisture. That is why it is perfect for use in rooms with high humidity..

- Frost resistance. Porcelain tile withstands temperatures up to -50 ° C.

- Fire safety. This building material is non-combustible.

- Resistance to temperature difference. Temperature changes from -50 to + 50 ° С will not affect porcelain stoneware in any way.

- Resistance to various chemicals – alkalis, acids, household pollutants.

- Environmental friendliness. Porcelain tile is absolutely safe for the environment and for human health.

Universality of application of the material

A distinctive feature of porcelain stoneware is the versatility of its use:

- facing of floor and wall coverings of bathrooms, bathrooms and kitchens, as well as stairs;

Porcelain stoneware in a country house

Facing the stairwells with porcelain stoneware, steps and sets for entrance groups are made of it

- decoration of office premises (its spectacular appearance will indicate the respectability of the company);

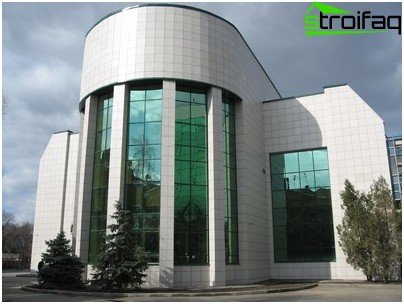

- Facade cladding

The facades of buildings decorated with porcelain tile look solid and impressive

- decoration of open terraces;

Wear-resistant porcelain tiles are preferred to be laid on sites that are not protected from atmospheric negativity.

- use as flooring in rooms where there is a large cross, such as restaurants, supermarkets, train stations, airports;

- lining of pools and other places where the surface is constantly in contact with water;

- facing surfaces on the street.

Porcelain tile is convenient not only for the construction of new buildings – it is also actively used in the reconstruction of old.

Porcelain tiles as flooring in a commercial center

In this industry, the scope of its application is unusually wide: cottages, schools, public, commercial and industrial buildings, balcony structures, etc..

Differences between porcelain tiles and tiles

Externally, ceramic granite looks no worse than tiles, resembling natural granite. It can also be matte, polished, polished, glazed and embossed..

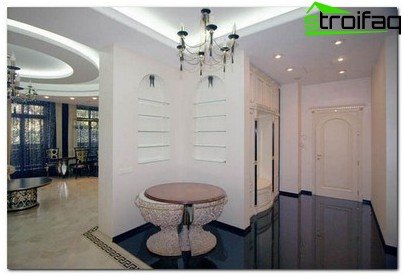

Semi-polished porcelain stoneware gives the room a presentable look.

The most significant difference between porcelain tiles and tiles is manufacturing technology. This material is painted through, throughout the depth, so if you scratch the top layer, it will practically not be noticeable, since the bottom is exactly the same texture and color. Even the deepest chips are not noticeable to the attentive passerby. But it is very important that the material looks like new for the entire life cycle.

An ordinary tile with the smallest cleavage exposes its foundation, because it is painted only on the outside. Tiles are usually painted at the last stage, glazing the usual base. Porcelain stained before molding – the whole composition, not the finished tile. Thus, the resulting material is uniform in color over the entire thickness.

Also, due to the difference in manufacturing techniques, porcelain stoneware, in comparison with ceramic tiles, has greater resistance to chemicals and temperatures, as well as greater hardness. This determines the universality of its application, which cannot be said about ceramic tiles, the scope of which is quite limited.

Ceramic tiles are most susceptible to destruction over time, since there are various microcracks and streaks on its surface. In ceramic granite, they are absent, and this classifies it as finishing materials not subject to the influence of time..

What is better tile or porcelain tile?

A definite answer to this question, perhaps, does not exist. It all depends on the purpose of the facing, the conditions in which the facing materials will be used and, not least, on the subjective assessment – the taste of the person. You can only give recommendations for cases when it is best to use ceramic granite..

Porcelain tiles at a pond in the country: durable material perfectly tolerates all the hardships of operation in an open area, in harmony with the landscape

- The first option is when the air temperature (both outdoors and indoors) can drop below zero, or atmospheric precipitation will affect the coating. Since the structure of porcelain is such that it practically does not absorb moisture, the possibility that it will crack in the cold is excluded. It is often used in open spaces: they spread the entrances to the cottages, a pond in the country, garden paths, it looks good by the pools.

Porcelain tile is indispensable as a floor covering in rooms with high traffic

Home decoration with granite indicates the high status of its owner

In the kitchen or in the bathroom, the conditions are not so extreme, so in these rooms you can easily lay ordinary tiles.

- The second option. Porcelain tile is indispensable as a floor covering in public, commercial, office premises with heavy traffic (he is not afraid of forklifts with boxes, ladies in high heels, falling heavy objects, broken glass), but not at all necessary in an apartment.

Currently, porcelain tiles are also used with pleasure for facing living rooms, hallways, kitchens and halls in country houses, the owners of which want to design rooms in a modern style and give them a presentable look for a long time. This is understandable, because correctly selected material for cladding is the key to comfort, coziness and good mood. Therefore, what is best for you – porcelain stoneware or ordinary tile – decide for yourself and do not let your choice disappoint you.