Do your own do-it-yourself flooring

Gone are the days when preparing the foundation of the floor was a dirty, incredibly costly and financially difficult procedure. A growing number of developers are inclined to install raised floors. In addition, even a full amateur in the construction business can correctly lay such adjustable floors with his own hands..

Any floor covering can be laid on an adjustable base. The only difference here will be the distance between the lags. If for parquet or for a laminate they can be placed after 500 mm, then for linoleum or for floor tiles this is not enough, otherwise the coating can quickly collapse. In this case, the logs are placed at a distance of 300 mm.

Content

- Advantages of adjustable floors

- Types of adjustable floors and installation technology

- Adjustable plywood floors

- Adjustable log floors

Advantages of adjustable floors

Raised floors overshadow all other bases, not only in their positive qualities, but also in their effectiveness. Let’s consider what advantages they possess:

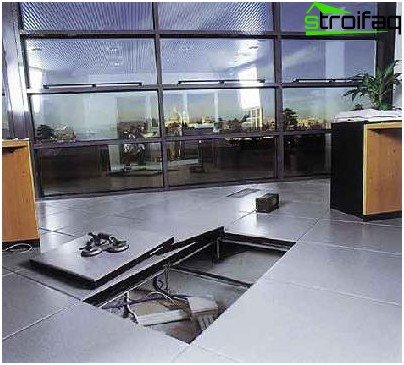

- The underground gap under the adjustable floors allows you to mount heating and electrical systems directly in it, which allows you to hide all communications. And in this case, it will be possible to do with the minimum number of connecting nodes required to bring the system elements to the right place. The main thing is to draw up an accurate plan of the location of pipes and cables, so that in case of any malfunction, not only the entire floor, but only the necessary section can be disassembled.

- The air gap under the floors does not allow the floor to cool. If a heater is placed in it, then this will not only reduce the heat transfer of the floor, but also increase its sound insulation properties.

- Again, the air gap provides excellent ventilation, which prevents decay of the lag, so you can use any materials (even rubber, ceramic tiles, etc.) as a floor covering..

- If the house has weak ceilings that do not allow placing a foundation with a heavy weight on them, raised floors with minimal pressure will be ideal.

- Not requiring drying time, they are quick to install..

- Experienced craftsmen guarantee that the newly designed adjustable floors of the new design, provided they are used correctly, can last more than 50 years..

The space under the adjustable floor allows you to place engineering communications in it

Types of adjustable floors and installation technology

At the moment, raised floors are laid in two ways: on moisture-proof plywood and on logs.

Adjustable plywood floors

If the room has a small ceiling height, then if it is necessary to level the floor, tenants try to save every centimeter of space. In this case, it is best to lay the coating on a special moisture-resistant plywood in a way that allows you to adjust its height.

Such a base is indispensable for small fluctuations in floor level in low rooms. It raises the surface by only 3 mm.

After installing and adjusting the position, all protruding floor elements are “cut off”

Consider the installation technology:

- The role of wooden logs is played by threaded bushings. Plywood should be prepared in two layers. In the sheets intended for the first level, holes for bushing are drilled. As a rule, for plywood with a size of 1.5×1.5 m, at least six pieces will be needed, the upper limit of the quantity is limited only by the wishes of the master.

- After all bushings are installed in the holes, the sheets are planted on the base with dowels. Now the surface height is adjusted using an ordinary wrench by tightening the threaded bushings. When setting up, you should definitely use the building level.

- The second layer of plywood plays the role of a finishing coating. We attach it with screws so that the seams of this layer do not coincide with the seams of the previous.

- Now you can begin to finish the flooring.

Adjustable log floors

If ceiling height allows, it is better to use wooden logs.

In this case, the floor surface rises by 50-60 cm, but as a result a magnificent air gap forms, the advantages of which we spoke above.

Adjustable floors on the logs are mounted much faster due to the presence of special adjusting devices that exclude a number of labor-intensive stages

Let’s consider such a laying technology in stages:

- Through holes are drilled in the logs, and their number depends on the planned floor load.

- After that, they are laid on concrete at a distance from each other, the most suitable for the selected flooring. We repeat, for tiles, linoleum and other soft and fragile floor materials, it should be at least 30 cm, and for parquet, laminate it is allowed to increase this value to 50-60 cm. The distance to the walls must also be maintained, it must be at least 60 mm.

- Fastening the lag to the base we begin from the ends. A hole is drilled in the ceiling to a depth of 40-50 mm. This must be done through the cavity in the body of the rack installed in this hole. For fastening, you can use any hardware: screws, dowels, wedges and others. The only requirement is not to tighten them immediately to the end so that the adjustment remains possible.

- A dowel is inserted into each hole and plastic bolts are screwed in..

- Adjusts the floor height by adjusting the height of the bolts.

- After the required height is set, all fasteners are tightened to the stop.

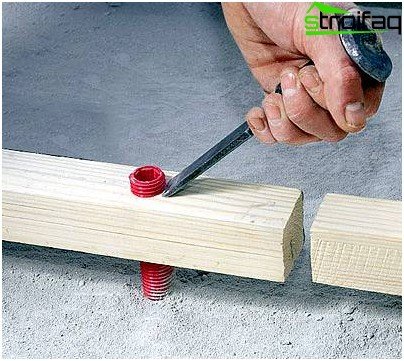

- The protruding bolt heads are removed with a chisel.

- Plywood sheets are fastened to the logs using self-tapping screws.

The protruding parts of the bolts are easily removed with a chisel

Previously, this method of leveling floors was used mainly in industrial premises, but now it is gaining more and more admirers among the ordinary population. It can be used in country houses, in apartments, on balconies, in general, almost everywhere, and the ease of installation allows you to perform these works yourself, significantly reducing the financial cost of flooring.