How to cut tiles with various tools

Regardless of the extent of the repair, it is difficult to ignore the various finishing works. Manufacturers of finishing materials offer a wide range of products for any category of consumers. There are a huge number of criteria, depending on which all these materials differ. One of them can be called the degree of ease of processing. When it is carried out with minimal labor, financial and temporary losses, this allows you to finish the repair much faster and more efficiently. So, if you wondered how to cut tiles, you must first stock up on special tools.

Content

- Tile Cutting Tools

- How to cut with a glass cutter

- Using a manual tile cutter

- Electric cutting machine

- The use of other tools

Tile Cutting Tools

Tile – a fairly common material for decorating rooms. As a rule, it is used for wall and floor cladding in the bathroom or in the kitchen. It is in these rooms that engineering communications often interfere with its laying, in addition, there are frequent cases when an even number of tiles simply cannot be placed on the surface of a wall or floor. In such situations, it is recommended to use one or another tool from the following list:

- glass cutter;

- manual tile cutter;

- electric tile cutter.

Great help will be:

- Sander;

- jigsaw;

- core drill;

- pliers;

- abrasive mesh.

The tool for the tile is selected based on the processing goals, the features of the tile and the nuances of installation. Let’s consider the most widespread tools and cutting technologies for this finishing material..

How to cut with a glass cutter

Glass cutter is recommended if you are laying wall tiles in small quantities. The cutting technology is as simple as possible. You will only need to pre-soak the tiles in water for about 1 hour. After that, using a conventional pencil or a more visible marker, a line of the desired incision is drawn.

It is worth remembering: it is impossible to carry out cutting if the distance to the edge of the tile is less than 8 mm!

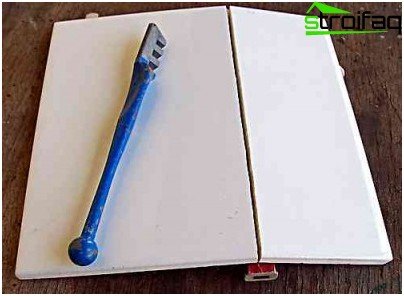

Then a glass cutter is taken, which follows, gently pressing on the tile, cut it according to the marking. In this case, the tile itself should be located on a flat and maximally stable working surface. Using this tool allows you to get a shallow incision on the facing material. It is possible to break off the tile along the cut line if you combine it with the edge of the working surface and lightly press on both sides. For the same purpose, an ordinary pencil can be used. Tile is also laid on it, which should be pressed on both sides.

Tile cutting tool – a glass cutter is used for facing small rooms, mainly for cutting thick floor tiles

It is worth focusing on the fact that this tile cutting tool is not suitable for use if you intend to process floor tiles. This is due to the fact that it is characterized by an increased degree of strength, and ordinary glass cutter simply can not cope with it. It is not suitable for large volumes of work. So, cutting more than 10 tiles will become time-consuming and extremely long. An alternative could be a manual tile cutter.

Using a manual tile cutter

A manual tile cutter will be a good helper when decorating rooms, if you are laying floor tiles or their number is quite large. The main difference between this tool and the glass cutter is the larger size of the cutting wheel. As a rule, its diameter is 15 mm. This allows you to make a deeper incision, and the work itself is much faster. Outwardly, the tile cutter is a bit like tongs. This association arises in connection with the presence of a special mechanism that allows breaking tiles.

Manual tile cutter for tile processing provides the ability to quickly and efficiently cut a large number of tiles

When cutting floor tiles, the corner on the bottom of the tile must be metal. For the wall cladding material, the plastic version will also work.

The cutting technology is the following process: tiles are laid on the base of the tool and fixed using a special ruler. Then its handle rises, and the cutting wheel is installed strictly on a pre-defined cut line. The movement of the handle is carried out in the direction of “yourself”. When you reach the edge of the tile, just click on it a little and the product will break in the desired place.

Electric cutting machine

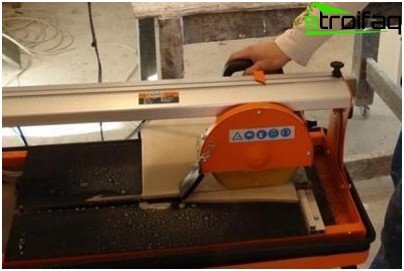

For large volumes of work, it is advisable to use a machine for cutting tiles, that is, an electric tile cutter. It allows you to easily cut the required number of tiles, regardless of its strength. Moreover, with its help it is possible to easily cut off even narrow strips of the product, the width of which is only 5-6 mm.

From a technical point of view, the electric tile cutter is a circular saw with a diamond blade, which has a solid and even base. Most models are equipped with a water tray. It is necessary in the process of cutting tiles to prevent cracks and chips from appearing on the surface of the tile. In addition, tile cutting occurs at a considerable temperature in the place of cut, so the water also cools the material well.

Electric tile cutter for sawing tiles is essentially a circular saw, used in the process of decorating public spaces, sports, shopping malls

When working with an electric tile cutter, do not forget about safety measures!

You must have eye protection glasses and special headphones that protect against noise. When using this device, the following sequence of actions is observed: the tile is laid on the base of the tile cutter and slowly moves towards the working saw. If necessary, make a cut approximately in the middle of the product, it is recommended to hold it with both hands on both sides of the saw. If a narrow strip is cut off, then you should keep the tile only from the widest side. Otherwise, there is a high risk of damage to the arm..

The use of other tools

There are a lot of tools that come in handy for working with tiles. So, if you need to break off a thin strip from an incised product, you can use ordinary pliers. Cutting floor tiles in an arc without any difficulties can be done using an angle grinder, however, it must be equipped with a concrete disc. After cutting, it is necessary to align the edges of the product, for which a grinding machine or abrasive material is used.

To make a round hole in a tile, for example, for laying a pipe, it is laid on a hard and even surface, and then a carbide drill is used. Ideally, this is a core drill designed specifically for tiles. If it is absent, holes with equal intervals are made along the perimeter of the future hole with a conventional carbide drill. Then, using a jigsaw blade (“cord”), it is necessary to cut through all the jumpers between the finished holes. The edges of the resulting hole are processed by a grinding machine.

Thus, a little time, knowledge and the necessary tool will allow you to cut tiles to wall and floor cladding as correctly as possible..