Bath boilers

What does the concept of “boilers for a bath” include? How do boilers differ from sauna stoves, are they different devices or the same thing? Is it possible to make a bath boiler yourself? Many Internet users who have decided to equip their own bathhouse are puzzled by such questions. To help lovers of the bath, we have prepared detailed answers to these questions. You will learn what boilers are, how to make boilers for a bath with your own hands and much more.

Content

- Boilers for baths: types and features

- What knowledge and skills are needed?

- We make a boiler for a bath

Boilers for baths: types and features

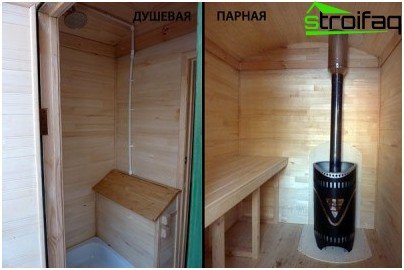

With regard to the bath, we can say that there are boilers exclusively for steam rooms, and there are boilers for the entire heating system of the bath house. If we are talking about large multi-room saunas, where there are washing, dressing rooms, restrooms, treatment rooms, then you can not do without additional heating boilers. They are placed in separate rooms, and in the steam rooms, stove-heaters are installed, which can also be in the form of boilers. Thus, in large saunas, two units are usually installed – boilers for a steam room and boilers for heating a room and hot water.

If we are talking about small, family baths, then the heating device there, as a rule, is one thing – a stove-heater or a boiler for a bath. With its help, the room is heated, steam is obtained, water is heated.

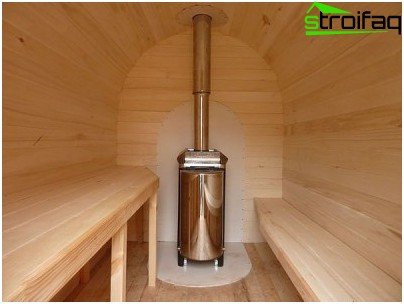

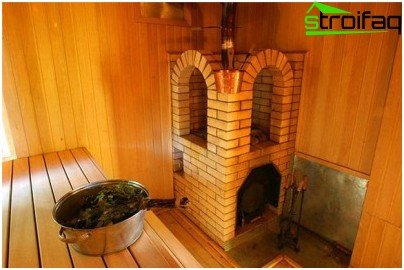

Metal boiler in the steam room

Variant of the location of the boiler in the steam room

A metal boiler lined with a brick fence

There are a lot of varieties of heating boilers. They can vary, for example, by the type of fuel used and be:

- solid fuel (work on wood, lignite or coal, slate, peat and other solid organic materials);

- liquid fuel (they work on kerosene, diesel fuel, fuel oil, distilled furnace fuel);

- working on gaseous fuels (liquefied or natural gas);

- electric.

As for the materials, then it is worth noting the features. For example, a cast-iron boiler for a bath is rarely used. It is not used in the steam room. If set, then in a separate room, and used for heating bath rooms, heating water.

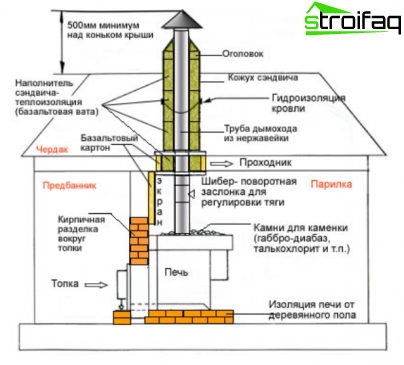

Boiler layout in a small family bath

Directly in the steam room can be installed:

- brick stoves;

- metal boilers;

- bricked metal boilers.

From time immemorial, the Russian bath was distinguished by a massive brick oven made by hand. But new technologies have appeared, and now factories mainly produce compact metal heaters. Unfortunately, not everyone can afford to buy this unit. Perhaps someone, having the appropriate building skills, wants to build a cauldron for a bath with their own hands. How to do it right will be discussed further..

What knowledge and skills are needed?

The first thing to consider is the type of fuel that is supposed to be used for a home-made boiler in the steam room, and with the type of boiler, respectively. Gas boilers for baths, like electric ones, is not the best option for self-installation. If you already decided on them, then you should buy a ready-made unit of good quality, because in case of improper assembly and installation, there is a high risk of emergency situations.

In addition, the gas boiler for the bath, the correctness of its installation, must be checked by the relevant regulatory authorities. And here solid fuel boilers, working on wood, making and installing will be much easier. For their proper installation it is necessary:

- Imagine how the boilers for the bathhouse look in the diagram – boiler drawings – this is what you need to get each homemade initially. In these drawings, it is desirable that it be seen how the boiler looks in section, from above and from the side, the parameters of all its parts are indicated separately, sketches of the most significant structural connections are made. It is important to know the “language” of the circuits, to have special terminology, to understand the principles of the boiler.

- Purchase consumables for the boiler. Some details can be found in construction supermarkets, but for the components of the furnace you have to go to a specialized store.

- Chop metal. A thick-walled box is to be cut out of standard steel sheets, which is the body of a metal boiler. To do this, you need to get scissors for metal of good quality (this will determine how smooth the pattern will turn out).

- Weld the steel body of the boiler. You will need the skills of a welder, because the cut steel sheets will have to be welded. The seam must be perfect.

- Brick the boiler. A brick box is created in order to soften the effect of intense heat coming from a metal furnace. Therefore, they build a brick fence-box with ventilation holes, passing along the perimeter of the boiler body. To do this, you need to know all the basic rules for bricklaying. The box should stand on a solid foundation, this also needs to be taken care of.

We make a boiler for a bath

We suggest you to make a simple metal stove-heater of an open type, in other words – a boiler, lined with brick.

Homemade metal bath boiler for a steam room

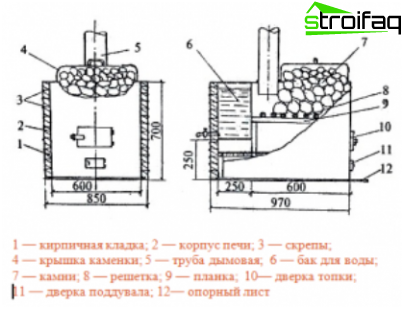

Scheme of a simple metal bath boiler

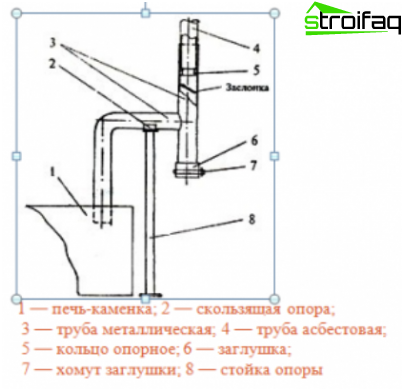

Chimney of a bath boiler

You will need:

- steel sheet 5 mm thick, from which the walls of the boiler will be made;

- steel sheet 10 mm thick for the bottom. The steel will be thicker, since the lower part of the boiler is exposed to the highest temperatures.

- reinforcing bars 3 mm in diameter. From them it will be necessary to make a metal mesh on which the stones will be located. These rods will be supported by channels welded to the walls..

- tin 1.5 mm thick and 15 cm in diameter and asbestos to create a chimney. A combined design is provided for the pipe, the lower part of the pipe will be made of tin. Upper – from asbestos. Both parts of the chimney should be connected together by a special flange connection with a mandatory damper. We suggest using just such a variant of the chimney, as it is the most fireproof: the asbestos part of the chimney is very well protected, it is not afraid of the effects of ultra-high temperatures.

- ready-made factory parts of boilers (water tank, faucet, doors, faucet, etc.).

Connect all parts of the boiler as shown in the diagram. If you have the appropriate building skills, then it will not be difficult to build simple boilers for a bath – the photos in our article and the schemes that accompany the text will help you with this. If you don’t have confidence in your abilities, and you’ve never done anything like this before, then it’s better to turn to specialists. The boiler is a fire hazardous device, so as not to risk the health and life of people, it should be designed and installed perfectly.