Ventilation in the bath

Ventilation in the bathhouse is a process that requires careful organization; in bathing construction it is considered one of the most complex. The correct ventilation device will protect people from carbon monoxide during stove heating, ensure a comfortable stay in the steam room, save fuel, distribute air flows evenly, and protect the walls of a wooden structure from waterlogging and rotting.

Content

- Principles of organization of ventilation in the bath

- If the firebox is in an adjacent room

- Condition: firebox inside the steam room

Principles of organization of ventilation in the bath

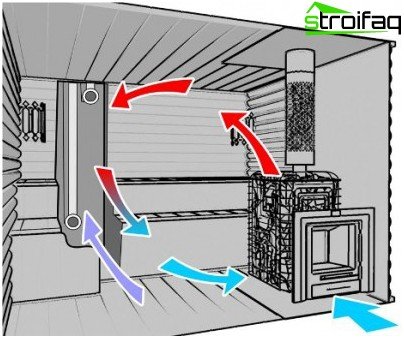

In the bath, the supply and exhaust (mixed) ventilation is usually used, that is, both the influx and exhaust of the air are organized.

To do this:

- supply (inlet) openings (vents) through which fresh air enters the steam room, and, if necessary, installations (fan, ventilation pipe). Also, air can enter through the windows, half-open doors.

- exhaust (outlet) openings through which heated air leaves the room, and / or installation (air can escape through the furnace blower – an opening below the firebox (combustion chamber), adapted to improve traction).

Exhaust hole in the bath

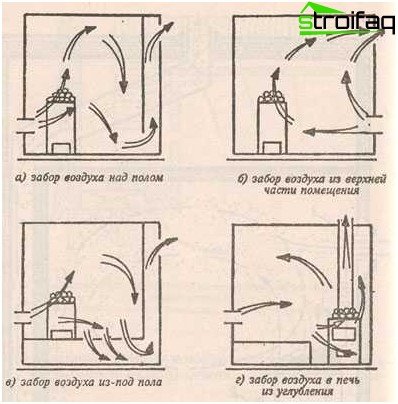

There are many ways to arrange the supply and exhaust openings, as well as different schemes, but to organize the most efficient ventilation system, the following principles should be followed:

- Supply air openings should be placed in the lower part of the room, closer to the stove-heater (so that the air heats up faster).

- Exhaust openings should be located on the opposite side of the supply, it is possible in 2 places – one above, the other below. This is done in order to better control the air flow..

- The higher the exhaust hole, the stronger the draft. The lower it is, the draft is weaker, so in the second case it is necessary to use a ventilation pipe.

- For the controlled supply and exhaust of air from the room, it is necessary to use special dampers (doors) on the exhaust openings, then opening or closing them.

- The air in the steam room should be updated at least 2-3 times per hour.

Possible ways of organizing supply and exhaust ventilation in the bath

It is worth noting that a lot depends on the type of bath. For example, ventilation of a Russian bath is most often carried out by simple ventilation.

But not always. It is worth considering the location of the furnace furnace – inside the steam room or in an adjacent room (due to the furnace tunnel). Next, we will consider how ventilation is arranged in the bathhouse, based on these 2 important criteria.

If the firebox is in an adjacent room

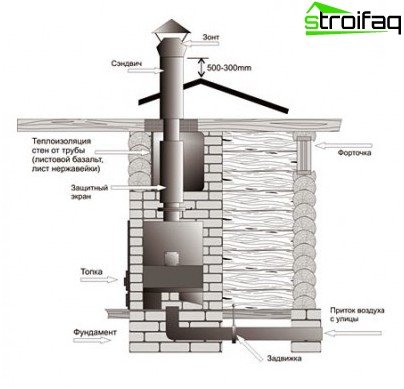

Consider the technology of the ventilation installation, taking into account the fact that the furnace is metal, it will be lined with brick with a 5 cm gap between it and the metal. For a Russian steam bath, this option of the furnace is the most optimal.

So, the firebox is displayed in an adjacent room using the furnace tunnel. This is the most common option, as it has several advantages:

- no rubbish in the steam room;

- the doors to the steam room do not open once again;

- You can install a large heat-resistant glass in the furnace door and enjoy the fire.

Ventilation technology for a bath with an adjacent firebox

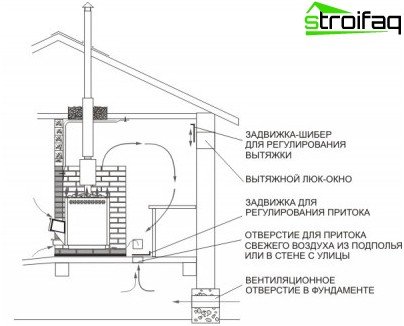

Further technology is as follows:

1. A furnace tunnel is lined with brick (a gap of 0.5 cm – 1 cm. Soft basalt wool will be placed in it, since thermal expansion may cause deformation and subsequent destruction of the tunnel or masonry) and then the furnace itself.

2. Air inlets are made. Here you can use one of 2 ways:

- Under the floor from the street, hold a ventilation duct 120% of the diameter of the chimney. Then remove it from the metal pre-heating sheet protecting the floor from fire (in case the coals fall out of the furnace). Place ventilation grilles on the channel outside and inside.

- The second method differs from the first only in that the supply of the ventilation duct will be outdoor. For the rest – everything is the same: lead from the street, output from the pre-heating sheet and put ventilation grids.

3. An extract is made (on the opposite wall and it is better diagonally from the supply openings). To do this, a ventilation duct is installed vertically at 20 cm -30 cm above the floor, which is led out through the wall through the ceiling to the street. The box can be sheathed with lining.

Important! The area of the supply air vents should be equal to the area of the exhaust. Otherwise, draft may occur, as a result of which the volume of fresh air will invariably decrease..

Condition: firebox inside the steam room

There can be 2 options:

1.If there is a stove-heater in the steam room, and the air, accordingly, enters its blower, then the ventilation problem is solved automatically. Fresh air is let in through the ajar door, leaving a gap of about 5 mm. This method is suitable if the fire in the furnace is constantly maintained, which ensures the operation of the blower.

2. In saunas in black (where there is no chimney), as well as where there is a furnace of short-term operating mode, a more advanced ventilation system is required. There can be many options for organizing a ventilation system.

Ventilation device in a bath with a furnace inside the steam room

We offer to organize everything using this technology:

- A special podium is set up on which the stove will stand. It will allow to bring ventilation ducts to the furnace. To do this, lay 3 rows of bricks (on the edge) from the wall, where the ventilation hole is located. The first row of bricks is laid near the wall, the second along the edge, and the third in the middle. Masonry is made 24 cm high up to the brick screen, then it is covered with a brick on top. But the last pair of bricks is not placed in the place where the furnace will be located. This is done with the expectation that it blows out of the box.

- The butt is laid.

- The second box, at the end of which it is necessary to insert a blowing oven door, is brought to an end. Under the basement door is something to put, otherwise it will constantly rub against the floor.

- It should turn out so that the first duct channel looks up under the stove, and the second with the door – into the steam room.

- On the wall, which is adjacent to the rest room, 2 channels for the doors are made at the level where the masonry passes. The distance is measured with a tape measure so that the 12 cm doors do not reach the top of the brick shirt. They can be opened and warmed up if necessary..

- An oven is placed on the podium. You can put it on metal plates or a corner to evenly distribute the load on the box area.

- The stove is bricked, leaving a hole for the passage of the fuel channel. There should be a gap between the brick and the stove 1-2 cm, which will later be closed with non-combustible material.

- Then a brick screen is put in which 2 convection doors (latches) are made.

Exhaust ventilation is installed in the same way as in a bath with a furnace outside the steam room.

Steam room ventilation system

Adjustment during use

It’s not enough to design bath ventilation, it’s important to be able to use it correctly.

Next, we will consider the general principles of ventilation and the specific ones applicable to our steam room with a podium..

General regulatory principles

- When the stove begins to be heated, all outlets should be covered (both exhaust and supply).

- After waiting when the temperature inside the steam room reaches the planned level, adjust the ventilation holes with the help of valves (doors).

- If during the bathing procedure there is a need to increase the volume of fresh supply air, open the supply opening even more.

- After completing the procedure, you need to open all the doors so that the steam room is properly ventilated

The temperature and humidity conditions are often determined by the sweaters by eye, focusing on their own sensations. But such an approach often does not allow an objective assessment of the situation, because much depends on the individual characteristics of the perception of an individual person. To know for sure at what temperature and humidity bathing procedures are carried out, devices are installed:

Bath thermometer

- To measure the temperature in the steam room, a thermometer is usually used (alcohol-based or powered by electricity, but not mercury). If you plan to use an electric thermometer, then a thermocouple should be placed in the steam room, but the indicator should be brought to the rest room or dressing room.

- The humidity level in the steam room is measured by a device called a hygrometer. This device in the bath is especially useful, it will help to determine in the steam room the desired highly humid or dry air mode.

Steam room system adjustment

It was described in detail above how to make ventilation in a bath with a firebox inside the steam room, the steps for creating a podium, carrying out duct boxes are laid out in steps. The design is specific, therefore, the principles of ventilation here will be special:

- When furnace kindling, the air gradually warms up and goes into the upper convection doors.

- We keep the lower doors open during initial heating, wait for the oven to warm up.

- Then we close the lower doors, the oven only works with open hatches at the top.

- At the time of hovering, only the blower door is located, located on the duct, necessary for the flow of air that is needed for combustion.

- After steaming, it is necessary to ventilate everything properly..

It turns out the following: Cold air through the box enters the oven, heats up and exits through the upper doors. Thus, the steam room is filled with hot air. It should be filled with them almost to the bottom of the box. After that, the cooler air, displaced by the hotter, will enter the street, warming everything in the way.

Do I need ventilation in the bath? It seems that after reading this article no one will have such a question. After all, the answer is obvious: of course, needed. Only here it can be organized in different ways, depending on the location of the stove, the type of bath and your personal preferences.