Wiring in the bath

The electrical wiring in the bath has a number of features. And this is mainly due to the high temperature and humidity in this room, which negatively affect the condition of the wires, as well as to the specifics of the flammable wood material of which the steam rooms are made. Correctly route the cable to the bathhouse and mount the wiring inside – vital.

Content

- Leading the power cable to the bathhouse

- Earthy laying method

- Cable routing “air”

Leading the power cable to the bathhouse

An ideal option would be if the bathhouse succeeds in supplying electricity from the central distribution panel through a dedicated power supply line. You can lay the power cable, bring it directly to the bathhouse in 2 ways: “earth”, when the wire is laid underground, and “air”, when it is conducted through the air. The methods should be provided for by the designs of the baths themselves.

Earthy laying method

This is the most reliable way, but it is not always suitable. Preliminarily, on a personal plot, all agricultural work should be completed and the fact that the wire does not have to be routed along the territory of the neighbor should be confirmed. Under the ground they lay the so-called “cable with armor” of the VBBShv brand with 4 copper conductors, the cross section of which is 10 sq. Mm. This cable is quite expensive, it costs about 200 rubles / m. But it is extremely reliable and durable thanks to the steel braid laid between its plastic shells. Accordingly, moles, mice and other rodents will not be able to bite him. Cable is not afraid of earth shrinkage.

It is not recommended to use metal pipes for laying the cable, as they are collectors of condensate, which reduces the service life of the wire. They are allowed to be used only in places where the cable goes along the pole or along the wall. In this case, the pipe is not used in height < 1.8 meters.

Laying the cable underground: bringing to the bathhouse in an “earthen” way

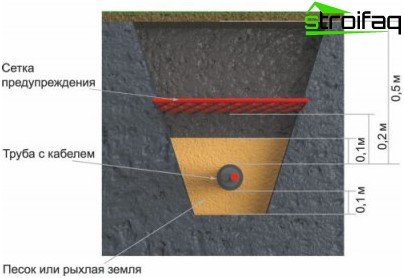

The sequence of actions when installing the cable underground is as follows:

1. Digging a trench not deep < 0.7 meters, at the bottom of which sand is covered with a layer of about 10 cm. Top wires are covered with the same layer of sand.

2. The cable is inserted into the building through the steel sleeve. It is necessary to protect the wire during movement and complete shrinkage of the wooden wall. The electrical wiring in the bathhouse must be carried out especially carefully and carefully..

3. The cable is released from its “armor” immediately before entering the shield. Only after this, the cable conductors are connected to the machine, making grounding and lightning protection.

Important! When installing an underground cable, exclude the possibility of dangerous stresses, its mechanical damage in case of soil displacement: create a reserve by placing the cable in a trench wave-like.

Cable routing “air”

If you choose a more economical method, deciding to run the cable through the air, then consider the following points:

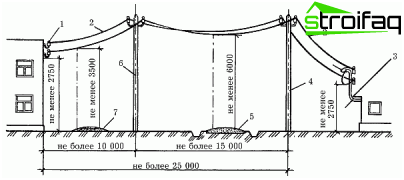

1. If the distance to the bath is more than 25 meters, it is necessary to put a support between the gaps. Aerial wire laying is carried out using the so-called extension, or on porcelain insulators.

2. The cable should be located at a certain, regulated height. Above the roadway, it cannot be placed below 6 m above ground level, above pedestrian paths – 3.5 m (not lower). The wire is attached to the bath at a height of 2.75 m above the ground.

Bringing the power cable to the bath “air” way

3. Commonly used SIP – self-supporting insulated cable. Its warranty period is 25 years. SIP cables (SIP-4, SIP-3, SIP-2A) have a special polyethylene weather-resistant coating and special load-bearing elements that are resistant to overloads. Its cross section should not be < 16 sq. mm with a capacity of up to 63 amperes. If the connection is single-phase, then the power will be equal to 14 kW, and if three-phase – 42 kW. The main drawback of SIPs is their problematic entry into the circuit breaker due to the low plasticity, they are difficult to bend.

4. SIP is introduced into the bath room (but not into the steam room itself, since aluminum wires cannot be placed there) through a metal sleeve. And completely different wires are introduced into the steam room – NYM, NG or VVG. Well-proven cable VVGNG-LS with a section of 3×1.5 (it is used to connect lighting), VVGNG-LS with a section of 3×2.5 (used to connect outlets). VVG insulation does not support combustion; the smoke level in case of smoldering is very low. For the transition, sealed copper-aluminum connectors should be used. The self-supporting insulated wire must be mounted on anchor clamps, the so-called tensioners..

Installation of electrical wiring in the bath: basic steps

In the process wiring installation Directly in the room of the bath, stages such as:

1. Installation of a guard;

2. Wiring from the shield;

3. Connection of fixtures;

4. Connection of sockets;

5. Electric furnace connection.

Rules for installing the electrical panel

The power system of the bath will be powered from the distribution panel. It is important to choose the best place for its installation, observing the following requirements:

1. Access to the shield should be free;

2. The place should be well ventilated;

3. The shield must not be placed in the steam room and other fire hazardous rooms;

4. Good illumination of a room with a visor.

Switchboard in the bathhouse (located in the relaxation room)

Usually the shield is installed in the rest room. It consists of a residual current device, introductory, as well as outgoing machines. Its upper part should be located at 1.4 m – 1.8 m above the floor, not less than.

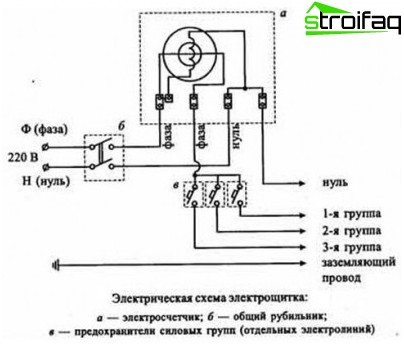

If the wiring in the wooden bath is single-phase, at least 3 conductors must be present in the power cable. In accordance with the new GOST, the color of the phase conductor must be gray, but wires from old stocks with white or brown phase conductor can get caught. This core is placed on the upper terminal of the input automaton. From the lower terminal, the phase core with the help of jumpers partially moves to the upper terminals of the outgoing machines, or is routed through distribution buses to the machines. The zero core (blue or blue) is placed on the zero block, the protective core (yellow-green) – on the protective block, or on the welded shield bolt. The phase conductors of the cables extending to the load are connected to the lower contacts of the machines. The outgoing and input cables are laid very carefully in the shield, then they are removed from the shield through the corrugated pipe. RCDs and circuit breakers should be installed taking into account the level of load on the cable.

We calculate the load on the cable, select the required section

It is necessary to know the load in order to correctly select the cable section. There are special tables for selecting the cross section of the wires, where its dependence on the estimated power of the devices is calculated. Electrical appliances usually indicate their power consumption, so you should pay special attention to this..

1. If only lighting devices are supposed to be placed in the bath, the total power will be approximately 1-2 kW.

2. If you do not use an electric furnace, the total power will be in the region of 5-6 kW.

It is advisable to consider 20% power reserve. For example, if the total power in the bath is 5 kW, then it is better to calculate the wiring by the value of 6 kW. With such power, a VVGNG-LS cable with a section of 3×4, that is, 4 sq mm, is suitable. Cables extending to the lighting, it is advisable to choose a cross-section of 1.5 square meters. mm (3×1.5), for sockets – with a cross section of 2.5 square meters. mm (3×2.5).

Installation of the electrical panel: circuit diagram

Select the input automaton

To do this, you need to know the total power. Then we calculate the current as a result of dividing the total load by voltage. For example, 6000/220 will result in 27 A. But the machine should be selected with a margin of approximately 32 A. The selection of outgoing machines by groups is carried out based on the same principle. It is advisable to sign each machine in the dashboard, indicating for which group of electrical appliances it is responsible.

Also next to the shield should be the wiring diagram of the bath. Do not forget to connect residual current circuit breakers that turn off power supplies in case of contact with water. This will help save lives in the event of an emergency. RCD with cutoff current will protect from fire. Ensure that the cores in the clamps of the terminal blocks are well fixed to avoid heating the section due to a loose clamp..

Electrical cable routing from the shield

Initially, the wiring diagram in the bath should be drawn. When drawing up the scheme and with the further practical implementation of the wiring plan, the following should be considered:

Wiring methods in the bath

1. It is recommended that the wiring of cables extending from the shield be made in one piece.

2. If the bath has wooden walls, then the wiring can be open, conducted over the wooden walls. It is forbidden to place wires in PVC pipes.

3. If the walls are brick – the wiring for the bath will be hidden, hidden behind a layer of plaster.

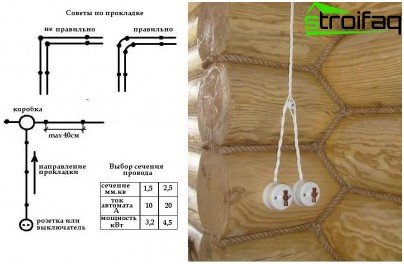

4. All cables should be mounted in a strictly vertical and horizontal position. There should not be excesses and twisting, which is indicated in the latest version of the PUE instruction. From the junction boxes, conduct wires only at right angles..

5. Try to place wires in the least visible places. They should not be laid in front of doors, closer than 50 cm from metal pipes and batteries.

Wire Connection Examples

6. Switches, sockets, as well as mounting boxes are not allowed to be used in rooms with high temperature and humidity. Over time, moisture will accumulate in them, and a short circuit will inevitably follow. This applies, first of all, to the steam room. Therefore, they must be located in dressing rooms or rest rooms.

7. Connect the wire strands by welding or soldering.

8. Use protective protective grounding.

9. Do not mount wires above the oven.

10. It is forbidden to place wires in metal sheaths and pipes.

Examples of improper wiring in the bath

Installation and connection of fixtures

Protection class fixtures for the bath should not be 75 watts. Plafonds should be used only glass, and the body – metal, connected to the protective conductor of the wire. The plastic case may become deformed. You should not place lamps on the ceiling, but only on the walls, since the temperature under the ceiling is usually the highest. The steam room usually uses low voltage (12V). For this purpose, step-down transformers, which are placed outside the steam room, are useful. It is also forbidden to install fluorescent lamps in the steam room.

Power Outlets

Sockets can only be installed on the walls in the dressing room or rest room at a height of 90 cm. Their protection class should not be < IP 44 It is advisable to use sockets with covers.

Norms for connecting an electric furnace

To connect an electric furnace, you will need wires that can withstand high temperatures (up to about 170 grams) and high power consumption, which is 4 kW on average). For these purposes, wiring in a cable channel with single wires of the PRKA, PMTK, PRKS or RKGM brands is suitable. A copper cable with a cross section of 3 * 2.5 mm can withstand approximately 5 kW of load. It is acceptable to extend the PMTK type wires to the installation box, which is located outside the zone of high temperature and humidity, and from the box to the shield conduct a regular cable (VVG 3×2.5).

When installing electrical wires, remember that proper wiring in the bath is the key to your comfortable and safe stay in this room. Before installation, carefully study the PUE (Electrical Installation Rules) in the latest edition – the desktop “Bible” of the electrician. Try to approach the issue as responsibly as possible, mounting the wiring with your own hands, or consult a specialist.