How to insulate a house with polystyrene foam

Warming of the house is an important stage of construction and repair, on the literacy of which a comfortable environment during the winter frosts depends. Various materials are used as heat insulators: glass wool, mineral wool, extruded polyurethane foam, but foam remains the leader in popularity. Therefore, if you are considering the question of how to insulate a house with polystyrene foam, the recommendations below will come in handy.

You can insulate the house, both from the inside and from the outside. Technologies do not differ from each other.

Content

- Necessary tools and materials

- Simple preparatory stage

- How to insulate a house with foam

- Sticking Styrofoam Sheets

- Reinforced mesh installation

- Final Stage – Finishing

Necessary tools and materials

In order for the warming process to go smoothly, it is better to worry about the availability of the following tools and materials:

Instruments

- hammer drill (can be replaced with a powerful impact drill);

- wallpaper knife (any other is also allowed for use, the main thing is that the blade is sharp);

- set of spatulas;

- a hammer.

Materials

- Styrofoam sheets. Select samples denser. The best option is polystyrene 25th density (40 mm);

- Fasteners. For fastening, plastic dowels with a wide hat are needed, in which nails will be hammered. The length of nails and dowels is determined by the thickness of the foam. You can make fasteners from screws and dowels, and put metal inserts under the caps;

Plastic dowel

Important! The dowel must enter the wall by at least 50 mm.

- Mounting glue. If one is not available, it is perfectly acceptable to replace it with cement-adhesive for ceramics. When calculating the adhesive solution, note that it will have to be applied not only to the sheets, but also to the reinforcement;

- Reinforced mesh. A mesh with cells of 5 mm is preferred, which is produced in rolls of 1 meter. The mesh will need to cover the entire surface of the mounted foam;

- Putty. For exterior decoration use any finishing or decorative plaster;

- Deep penetration primer.

Simple preparatory stage

Before embarking on the main task, code-named “how to properly insulate a house with polystyrene foam”, preparatory measures should be taken.

It is necessary to clean the walls of old materials: lime, paint, tiles, plaster. Pay attention to the surface: perfectly even walls are not needed, but there should be no obvious hollows and ledges, because this can not only interfere with the work, but also spoil the final result. For better adhesion with glue, impregnate the surface of the walls with primer.

How to insulate a house with foam

The installation of polystyrene is not difficult. All you need is a little patience and a minimum of theoretical knowledge.

Sticking Styrofoam Sheets

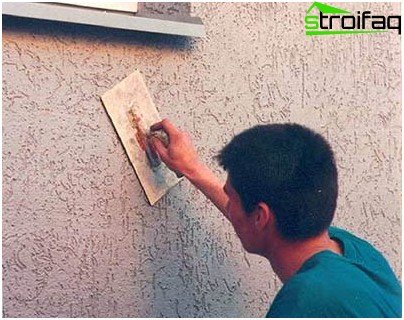

Spread the glue with water and apply it to the wall with a notched trowel. The glue should not be too thick, but it should not run down the wall either.

It is important! It is not necessary to apply glue to the entire surface – a square under the first sheet is enough. Otherwise, the glue will dry before you can finish the construction area..

Next, attach a foam sheet to the wall and press it firmly. Fix the sheet in the corners and center with dowels. The second sheet is mounted in the same way. Joints between sheets need to be glued. For greater reliability, fasten the sheets with iron inserts.

Fasteners with iron inserts

If necessary, cut a piece of polystyrene foam, this is done using an even bar and a pointed knife. No power tools needed for cutting.

Reinforced mesh installation

The mesh must be attached to the same adhesive. Cut it with a regular knife into strips along the length of the wall, and then glue each strip separately.

It is important! Smooth the glue and mesh with a spatula so that it does not jam..

Reinforced mesh installation

To avoid the formation of cracks, glue the mesh with an overlap. For better adhesion of the reinforced mesh, the foam sheets are primed..

After drying, the surface is additionally smoothed with glue, which will provide a strong reinforcing layer that reliably protects the foam from atmospheric and mechanical stress. Next, apply another layer of primer.

Final Stage – Finishing

After the final drying of the primer, the final finishing layer is applied in the form of decorative plaster. The layer thickness is approximately 1.5-3.5 mm. After application, the plaster is rubbed and the surface is dried.

Finishing of home insulation with polystyrene – application of decorative plaster

That’s all! The house is insulated, which means that neither a cold wind nor wet snow can harm your home, in which it will be cozy and warm.