How to properly mount insulation of a timber house for siding

Wooden houses are still favorites in the private housing market, because they have the best microclimate, easy to breathe and no harmful substances are released in the heat. But the level of heat saving cannot be ensured to the maximum due to one tree, because the cold from the street will penetrate in the same way as clean air, i.e. through the pores of the material. In addition, the tree is short-lived, and over time, its structure begins to collapse, opening more and more loopholes for the penetration of the cold. Therefore, the owners try to insulate the walls from precipitation with the help of finishing material and additionally insulate. Very often, the insulation of a timber house is mounted for siding, and some owners just sheathe the log house. But the log and beam have their own characteristics of warming. Let us dwell on them in more detail..

Content

- How is the insulation of the log house outside?

- Recommendations for the external insulation of a log house

- What materials are better to insulate?

- Creating a wall cake with external insulation of timber houses

- Selection of insulation thickness

- Vapor barrier installation

- Installation of the lathing

- Insulation fixing

- Waterproofing

- Creating a ventilation gap

- Siding Installation

How is the insulation of the log house outside?

A house made of solid trees looks very luxurious, so installation of siding with insulation should not be done until the tree begins to collapse. If you are concerned about the purely economic aspect, then experts have calculated: the cost of insulation and finishing in a log house for temporary residence (for example, a summer residence) will pay off only after 40 years, and in a residential building – after 15-20. But without warming you will keep the tree as healthy as possible, because there will be no barriers to ventilation.

Do not try to insulate the log house outside until the tree begins to deteriorate, because you can not control the condition of the wood under the finish

Another question is if the tree is old and in some places it began to crumble, then it is advisable to put protection from the sun and precipitation in order to suspend the destructive process. But even in this case, do not rush to do insulation, because no matter what heat insulator you choose, it will turn out to be bad for preserving wood.

When installing insulation using basalt or fiberglass heaters, respirators are used so that flying small particles do not get into the airways

So, basalt and fiberglass heaters, such as stone or mineral wool, contain many particles in suspension. It is easy to see when you shake the stove. Then the space around you will be filled with the smallest flying particles. And since the air will go between the insulation and the log, all the suspensions will inevitably penetrate the structure of the tree, clogging the pores, and some will get to the premises, and you will have to breathe this. In addition, the steam leaving the house will penetrate into the loose structure of mineral wool. And if you do not provide proper ventilation, cotton wool will lose its heat-insulating properties. Moisture will also settle on the tree, and the meaning of warming will come to naught.

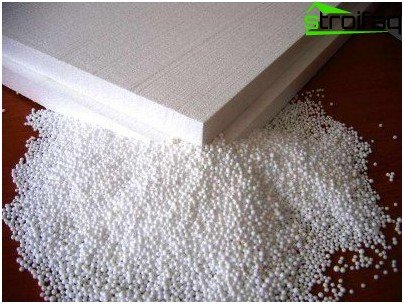

Despite the high level of heat saving, polystyrene materials are contraindicated for wood, because they do not let moisture in and provoke wall decay.

It is not necessary to use polystyrene foam materials for insulation, because, regardless of the quality of heat saving, they poorly pass moisture. This means that the steam from the rooms will not break through the insulation at all in order to get to the street and weather. And in cold weather it will be condensed on that side of the log, which is turned to the insulation. Instead of a warm house, after 10 years you will have a rotten log house in which you will have to change most of the crowns. Question: do you need it?

Recommendations for the external insulation of a log house

But to protect the old building from natural factors is still worth it. It is possible to carry out wall insulation from the inside, and from the street it is enough to simply sew up the log with siding. With proper installation, you will extend the life of the wood by about 10 years. For plating, you will need a vertical crate. It should be made only from a wooden bar. It is tough and easier to put on the uneven surface of the log. The thicker the crate, the better the tree is ventilated and the less likely it is that the cold will enter the rooms. Therefore, it is recommended to use a beam of 50-ku. In addition, it must be remembered that the siding is not stuffed from the roof to the beginning of the house, but with a gap of 5 cm on both sides. This is necessary so that moisture coming out of the tree can break out.

To warm the corners, you need to cut the log flush with the wall, tighten the corner with insulation and nail the boards tightly on both sides

The only place where insulation is recommended is the corners of the house. They freeze more than the main walls due to the location of the wood. The best option for warming corners is mineral wool, because it is well ventilated. But it is better to lay it not under siding, but under a board or lining, creating something like a column, as the old Russian masters did. If you can combine such a finish with siding, then the log house will be protected from freezing as much as possible.

What materials are better to insulate?

Unlike log houses, the insulation of walls made of timber from the outside is justified not only by increasing the thermal insulation properties of the structure. This saves usable floor space. If to sheathe the walls from the inside, then for every 10 sq.m. you will lose about a meter of usable area.

The technology of creating ventilated facades is considered to be the most suitable for wood, because it allows the walls to breathe, which means that the microclimate in the house will not change. And siding is one of the best options for outdoor decoration.

If we consider what and how to insulate a house from a bar, then the least suitable will be polystyrene materials (polystyrene, foam, etc.). By themselves, these heaters work perfectly on brick, block buildings, but to wooden walls, regardless of the type of material, they do not fit, as mentioned above.

Roll insulation is inconvenient to mount on the walls, and over time, under their own weight, they begin to crawl down

The choice of basalt and fiberglass insulation is huge, and you can find both budget options and quite expensive. All of them work approximately the same due to the loose structure that perfectly retains air. Just some of them (mineral wool) can absorb moisture and lose their properties because of this, while others (stone wool or glass wool) are devoid of such a drawback. But if you create the right wall cake, then the brand of insulation is absolutely not important. Consider installing external insulation with basalt wool for subsequent siding.

Creating a wall cake with external insulation of timber houses

Selection of insulation thickness

It is best to insulate a timber house from the outside not with rolled, but with plate heaters. They have higher stiffness, and over time they will not creep down. Select the thickness of the cotton wool taking into account the thickness of the beam. If the walls are made of 150 mm timber, then a 100 mm insulation is laid. If the tree is thicker – 200 mm, then 50 mm cotton wool is enough.

Vapor barrier installation

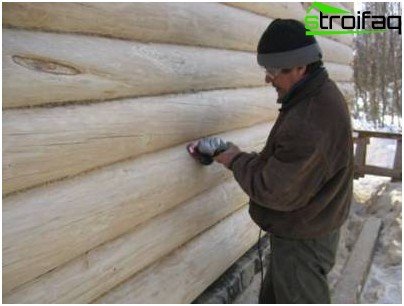

To protect the insulation from vapors leaving the interior, the timber is coated with special waterproof mastics or lined with a vapor barrier film. The second option (film) is preferable, because its insulation quality is higher. The film is fixed to the wall with a stapler, and the joints are glued with tape.

A vapor barrier film protects the insulation from moisture from the premises, and prevents moisture from the tree from entering the next layers of the pie

Installation of the lathing

It is recommended to put only a wooden frame on the timber. Metal profiles will be colder in winter than the main wall, and there is a chance of condensation between them. The crate is packed strictly vertically using a plumb line and level, because siding will be mounted on it. And any curvature will result in skewed exterior trim.

The step of the bars is selected taking into account the width of the selected insulation so that it can be laid without squeezing or wrapping from the sides. The distance between the holes for fastenings in the siding is also taken into account (find the instructions in the installation instructions about this). Be sure to pre-coat the entire framework with an antiseptic to prevent decay..

Insulation fixing

When the crate is ready, they begin to warm the house from the beam: they fix the basalt cotton wool with the help of special dowel umbrellas, trying not to press it strongly against the wall. A cheaper option for fastenings is self-tapping screws with a length of 10 cm. To prevent their hat from “drowning” in the insulation, cut out circles from roofing felt or plywood and apply them before twisting the self-tapping screw to the cotton wool. Approximately per square meter of insulation there are 5 fasteners.

Waterproofing

After the insulation is laid, it is necessary to protect it from moisture from the outside. For this, a superdiffusion membrane is laid on the crate. This is a special film in which the surface consists of pores resembling funnels. The wide side of the funnel is laid to the insulation, and the narrow neck to the street. This will provide an outlet for fumes accidentally caught in the insulation, but will not let water molecules from the siding.

Creating a ventilation gap

On a wooden frame, it is necessary to fill the slats with a thickness of 5 cm so that free space forms between the siding and the film. This will allow moisture trapped under the finish to weather and not condense the membrane with condensate. The movement of air is created with the help of ventilation slots during installation of the siding, laying it not from the beginning of the roof to the bottom of the wall, but not reaching them a couple of centimeters.

To prevent condensation from forming under the siding, create ventilation gaps with the help of rails stuffed onto the crate

Siding Installation

On the rails, they fill profiles, leveling the horizontal, and begin to assemble the siding from the bottom.

If the insulation of the house was created in compliance with the installation technology, then the dampness of the wooden structure is not terrible, and you will feel the quality of heat conservation already in the first winter.