The owners of “single” balconies (located separately from the wall) and residents of the upper floors in old houses are faced with the question of building a roof on the balcony. Such balconies do not have a roof in the form of a slab on top, and before the roof over the balcony of the last floor was not provided. But if you want to make full use of the space of the balcony, not only when it is warm outside, but also in cold and damp weather, and even more so if it is planned to expand and warm it, then you will definitely need a roof to the balcony. About how to properly build it, and will be discussed in this article.

Content

- Types of balcony roofs

- Dependent roofs

- Independent roofs

Types of balcony roofs

The question of the roof device on the balcony arises among residents of the last floors

A few basic requirements are imposed on a balcony roof: its design must be reliable and strong; it should be aesthetic, so as not to spoil the look of the facade of the house.

According to its design, there are two types of roofs:

- dependent (performed in conjunction with the supporting structures of the house);

- independent (attached to the outer walls of the house without racks).

Let us consider in more detail each of the options.

Dependent roofs

This roof option requires more material and time. But this method is worth choosing, especially if you plan to completely glaze the balcony, when the vertical racks are useful for installing a double-glazed window.

Dependent roof structures are reliable and can withstand heavy loads, so you can choose any roofing material for them. An advantage is that the length and other dimensions of the dependent roof can be any. In addition, glazing profiles are easily and conveniently attached to it, it can be insulated with various heat-insulating materials and this makes it possible to equip a warm balcony.

Independent roofs

This version of the balcony roof is simpler and requires less financial investment. But this method also has disadvantages:

- for wide balconies, hinged roof options are obtained with a large extension, and this makes the structure heavier, making it unreliable;

- only light materials are used to cover the independent roof, such as corrugated board or corrugated sheet;

- the inability to thoroughly insulate the balcony, because it is not possible to perform its high-quality glazing.

Important! Since the roof on the balcony of the last floor of the house will have to withstand heavy snow loads, it is not recommended to use the hinged roof option.

Selection of materials for balcony roofs

The most common materials for a balcony roof include:

- various steel sheets (corrugated board, laminated corrugated board, corrugated sheet, galvanized, etc.);

- soft roofing materials (bitumen, roll roofing, flexible tiles, ondulin);

- sheets of cellular polycarbonate or special double-glazed windows for the roof.

The most profitable material in terms of price / quality ratio is profiled flooring. They can cover any balcony roof. It is characterized by good structural rigidity, therefore it does not deform under the influence of snow and wind loads, which means that in the future it will not be necessary to repair the roof. The only drawback – it is required to conduct sound insulation of such a roof. But this problem in the presence of a wide variety of soundproof materials today is easily solved.

Profiled sheets – the most common material for covering balcony roofs

When using soft materials for the roof, there is no need for additional sound insulation of the roof, but it will be necessary to create a more rigid frame for it.

Polycarbonate sheets are used for the roof on the balcony when a warm glazing option is assumed. This material is 15 times lighter than glass, but with apparent fragility it has high impact resistance and resistance to UV radiation, so it does not deteriorate during operation and does not lose its transparency. Its temperature range is 45 +80 degrees Celsius.

The polycarbonate roof is durable, resistant to ultraviolet radiation and does not lose its transparency over the years

The most expensive material for roofing is double-glazed windows for the roof, which are made of tempered glass. They are reliable, perfectly retain heat, do not let moisture in, serve for a long time. Double-glazed windows are not afraid of any mechanical influences, since the materials used for their manufacture are strong and reliable. Glazing of balconies with a roof with the help of double-glazed windows is the simplest option, which does not require large power costs, since the manufacturer makes and installs the double-glazed windows. Finally, the transparent roof on the balcony looks very impressive.

A double-glazed roof is the most expensive, but also the most original and attractive roofing material.

Roof construction on the balcony

In order to figure out how to make a roof on the balcony, consider the option of an independent roof device using a profiled sheet. To do this, prepare the following materials and tools:

- pre-welded support trusses from corners 60. Their number is calculated along the length of the balcony, taking into account the step between them of one meter;

- profiled sheets;

- bolts or anchors 10 centimeters long;

- bars (40×40 cm) for the lathing;

- screws with gaskets;

- sealant;

- wood preservative;

- scissors or a hacksaw for cutting metal;

- polyurethane foam;

- cement.

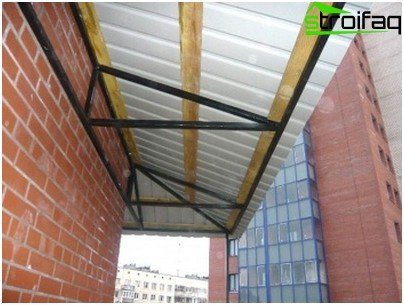

Installation of an independent roof: a frame of metal trusses is attached to the wall

Roof installation is carried out in the following sequence:

- Pre-prepared metal trusses are fastened with anchor bolts, deepening them into the wall by 8 cm.

- On metal trusses, the installation of a wooden crate from beams is carried out.

- The wooden structure is treated with an antiseptic to protect against rot..

- Profiled sheets are cut to the desired size using special scissors or a hacksaw for metal. It is not recommended to use a grinder for cutting sheets, because their edges in this case will quickly become worthless.

- The resulting profiled sheet elements are attached to a wooden crate using screws with gaskets.

- The gaps formed between the sheets and the wall are filled inside with mounting foam, and the outer parts of the joints are sealed with cement mortar (cement with sand 1: 3) and treated with glue-sealant.

- If you plan to repair the glazing, then at the edges of the roof you should mount the bars, to which the frames will then be attached.

- The balcony is glazed. Foam is injected into the gap between the roof and the frames, and waterproofing with sealant is carried out from the outside. It is also possible to mount ready-made double-glazed windows.

- If the balcony is intended to be used as an additional living space and it needs to be insulated thoroughly, then it is recommended to use membrane waterproofing under the profiled sheets.

On the underside, the roof structure is insulated with any heat-insulating material (usually mineral wool), and then a vapor barrier film is hemmed to the insulation. It is better to use mineral wool with foil to prevent it from spilling inside the balcony.

Roof insulation – a necessary procedure when installing a glazed insulated balcony

Tip. We must not forget to tightly join the insulating materials: solid – with mounting foam, roll – with adhesive tape.

And further. If the balcony is airtight, it is recommended to equip the balcony roof with a ventilation hole so that oxygen enters the apartment. For some reason, this recommendation is often neglected..

Some tips on how to make a balcony roof durable

There are some nuances that need to be considered in order to make a reliable construction of the balcony roof:

- the wooden beams selected for the crate should not have knots, notches and cracks, the products should be absolutely even;

- you need to study the instructions for the selected roofing material in order to understand what power loads it withstands and whether it is suitable for the weather conditions of a given region;

- wooden surfaces must be treated with anticorrosive and fire-resistant substances;

- it is necessary to check whether the corner frames are firmly attached to the wall, and the roof to the crate;

- in the process of laying the insulation, it must not be allowed to get wet;

- you can not save on the quality of the materials used.

It should be remembered! Making the roof of the balcony with your own hands is quite a dangerous thing, since the work is carried out at altitude. In this case, it is better to first weld the supporting structure on the ground, sew a crate and corrugated board on it, and only then fix it by lifting it to the desired height.

At this stage, we can assume that the installation of the roof on the balcony is completed. It remains only to complete the interior decoration with suitable material for this – lining, drywall or siding. Outside, they also finish with various finishing materials. It is only necessary to pay attention to such characteristics as impact resistance, durability and surface waterproofing.