Noise is a constant companion of people living in big cities. Its excess causes fatigue, nervousness, irritability. Therefore, it is very important to ensure reliable sound insulation of the external coatings of the building, and especially the roof, since it is the most vulnerable part of the structure. The roof is directly affected by precipitation, temperature changes, and the quality of its coating is directly related to sound insulation. And given the tendency of recent years to settle in the attic space in order to expand the living space, protecting the roof from atmospheric precipitation and extraneous noise is becoming one of the main criteria in building a house. Soundproofing the roof of the house is especially important for roofs made of metal sheets, metal tiles, since they have high resonating properties.

Content

- Why is the roof rustling?

- Common Ways

- roof soundproofing

- Choose a soundproofing material for the roof

- Features of the sound insulation of the roof

- Installation of soundproofing material

- Soundproofing the roof from the inside

- Some tips from professionals

Why is the roof rustling?

In the market of modern materials for roofing, the main share (up to 80%) falls on metal roofing and corrugated board. This is due to the high quality of these materials and the long service life (up to 50 years) of such a roof. But with all the positive qualities, metal roofs make a lot of noise, for example, with strong winds and a drumming rain, which creates a certain discomfort. In this case, you can’t do without creating a reliable layer of sound insulation of the roof when installing its structure.

Roofs coated with metal coatings have high resonating properties, so they must be insulated

However, often the generation of noise is not associated with the characteristic features of the roofing, but with illiterate actions when installing the roof:

- the roof will sag in some areas and resonate even with slight gusts of wind, if the frame under the metal roof is installed unevenly, using battens of different thicknesses arranged in alternating steps;

- while saving mounting hardware (self-tapping screws) for installation, the roof can emit strong sound effects even during light rain or wind, therefore, the recommended minimum of self-tapping screws – 8-10 pcs. per 1 square meter of metal coating. It is also important to use only those screws that are recommended by the manufacturer of the roofing material, and not any that are lying around on the farm;

- improperly performed cutting of sheets, and their laying in a stretch leads to deformation of the material even without load. With strong cooling or solar heating, the deformation of the roof intensifies, and it begins to buzz strongly;

- the noise insulation of the metal roof should be the denser the smaller the angle of inclination of the supporting structure will be – these are the rules according to the physics of rain drops falling on sheet material.

It is not easy to change the configuration of the roof in order to achieve acoustic advantages, and it is not difficult to take into account the first three points when installing the roof, especially since this will significantly improve the quality of soundproofing.

Common roofing sound insulation methods

There are some of the most common ways to soundproof a house roof:

- The use of roofing materials with special properties. One of them, for example, is a metal tile with a sound-absorbing effect..

- Laying the speaker system (additional sound-absorbing layer) on the waterproofing layer or on the crate and rafters. Elastic and viscous materials, such as polystyrene, are considered suitable for this..

- Soundproofing roofs from the inside. Between the rafters, additional plates of sound-absorbing material are laid, and the insulation layer is covered with lining, drywall, ceiling tiles (they also absorb sounds).

- They choose universal materials that can not only insulate the roof, but also solve the problem of hydro and sound insulation. These are polystyrene foam slabs and mineral wool.

- The metal roof is covered on top with a special mixture made of transparent varnish and basalt chips. Immediately before laying, the inside of the metal is coated with this mixture and quickly fixed until the layer has dried.

- Finally, arrange a soundproof pillow (attic) between the room and the roof of the house.

However, sound insulation of the roof of the house is carried out in most cases using special soundproofing materials. What parameters do they choose??

Choose a soundproofing material for the roof

When selecting noise insulation materials, the main criteria that need to be followed are two parameters: the first is the sound absorption index and the second is the dynamic modulus of elasticity. Each of them significantly affects the sound insulation quality..

Sound absorption index shows how much of the sound waves was absorbed by the material. A good quality insulating roofing material has a noise absorption index of at least 0.6. For example, the index of the tree is 0.08-0.16, the foam 0.16-0.26, but mineral wool has an index of 0.65-0.8. Therefore, mineral wool, ecowool (cellulose insulation) are considered the best soundproofing materials. They create a reliable thermal barrier and at the same time protect the house from extraneous noise. Polyfoam can not be recommended for noise insulation of the roof.

Dynamic modulus of elasticity – second parameter. It characterizes the elasticity of the material. The lower the value of this parameter, the higher the sound-absorbing properties of the material. In other words, dense material reflects sounds better than loose. If we compare, for example, the sound-reflecting properties of fiberglass plates and foam, we can see that the first insulators are better than the second.

A noise-insulating material based on foamed polyethylene of the Isolon brand will create a reliable thermal barrier and at the same time protect the house from extraneous noise

Features of the sound insulation of the roof

Undoubtedly, the choice of quality materials is very important for the device of noise insulation of the roof. But it is equally important to follow the rules of its installation, so that all the qualities of the insulation, including sound insulation, are manifested in full. The main factors affecting the quality of sound insulation are:

- high-quality acoustic isolation in places adjoining the rafters and the inner lining of the attic;

- the presence of a gap between the soundproofing material and the enclosing roof structure.

If these requirements are taken into account, then the effectiveness of the anti-noise barrier is beyond doubt.

Installation of soundproofing material

Noise-insulating materials are laid when performing general roofing, which allows you to initially make the right roofing cake with thermal, waterproofing and acoustic protection.

It looks like a properly arranged roofing cake with waterproofing, thermal and acoustic protection

Installation of noise insulation of the roof is carried out in the following order:

- The waterproofing is laid on the rafters, the battens of the battens are stuffed on it. Each element is pre-treated with a waterproof glue solution or foam. Process immediately before the fasteners the side that is adjacent to the waterproofing layer.

- Next, soundproofing for the roof is laid, leaving an allowance for the rails. The thickness of the rails should correspond to the thickness of the soundproof material. From above, the material will be pressed against the roof with thermal insulation, so it does not need to be fastened, but it should be laid exactly, without gaps. When calculating the amount of sound insulation, you need to add about 10-15% of the total area to cut.

- Soundproofing material must be laid under the insulation (polystyrene foam, polystyrene foam, mineral wool). If the roofing cake turns out to be too large, additional counterracks will have to be stuffed onto the frame to securely fasten the roofing.

- At the last stage, the installation of the roofing is carried out. Between the crate and metal sheets, special insulating gaskets of felt, rubber or polyethylene are laid, which prevent the penetration of cold and vibration under the roof surface.

Soundproofing the roof from the inside

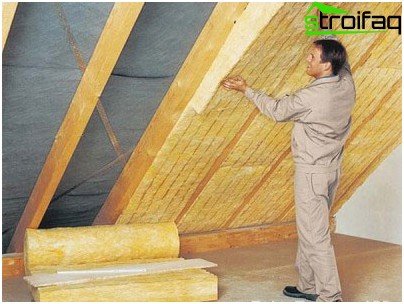

In cases where it is impossible to carry out work under the roof surface, the installation of a soundproofing layer is carried out from its inner side in this way:

- soundproof sheet material is laid in the gap between the rafters without gaps and gaps;

- the material is cut into pieces (they should be 8-10 centimeters longer than the inter-rafter gaps) that sit tight and hold well inside;

- to prevent accidental displacement of the material from above, wooden slats are stuffed, holding it in place.

Laying the sound insulation layer from the inside is a more complicated option from the point of view of installation, but in this case, you can achieve good results so that the house is as quiet and warm as possible.

Sound-absorbing material is placed in the space between the rafters – mineral wool or fiberglass, which simultaneously performs 2 functions – sound insulation and heat insulation

Some tips from professionals

- The roof is erected for decades to come, therefore, it is not worth saving on heat-insulating plates that provide effective sound insulation of the roof. Get high-quality soundproofing materials with a high sound absorption index.

- Use mineral wool materials in combination with new soundproofing methods, which include the use of special soundproofing fasteners for acoustic structures.

- Without fail, lay all the layers of roofing “cake” recommended by specialists. Do not think that you can do without any of them. Each material has its own separate purpose..

- It is better to purchase all the components of the roof structure in one place in order to save on discounts and minimize the risk of purchasing fake goods (this is practically impossible in large construction stores).

And in conclusion – the most important advice. Having spent considerable money on the purchase of expensive roofing materials, do not save on attracting qualified specialists for the installation of the roof. Professionals will do the work in strict accordance with the technology that is indicated by the manufacturer in the instructions, and this guarantees peace and quiet in your home.