Waterproofing a flat roof is a necessary measure to protect the roof from the damaging effects of precipitation. This is an important stage, neglect of which can have a detrimental effect on the integrity of not only the roof, but also the building itself. Therefore, all roof waterproofing must be carried out during construction, and not after a couple of years have passed.

Content

- Types of Flat Roofing

- Materials for waterproofing a flat roof

- Preparation of the roof for laying (applying) the waterproofing layer

- Roofing up

- Stacking roll surfaced materials

- Application of liquid rubber on the roof

Types of Flat Roofing

Flat roofs can be exploited and non-exploitable. The second option, unlike the first, does not provide for a rigid base intended for laying a waterproofing layer. As a heater for such a roof, soft heat insulators are usually used. Unexploited flat roofs are built on buildings where there is no need for regular maintenance of the roof. And their design is a kind of pie, consisting of a concrete slab or metal sheet, insulation and a finish coating made of rolled materials.

The exploited flat roof is an improved version of the traditional roof. Such a roof has a rigid base, capable of withstanding the loads arising during the repair work. The waterproofing layer on the operated roof is laid under the insulation, which helps to protect it from temperature extremes, mechanical damage, exposure to the sun and freezing-thawing cycles. Naturally, the service life of such a roof is significantly increased.

Materials for waterproofing a flat roof

Regardless of the type of flat roof, its waterproofing is performed in the same way, with the same materials. Most often, builders use roll materials for this purpose, which include roll-over-weld and polymer-bitumen materials, roofing material and PVC membranes. In addition, it is possible to use bituminous waterproofing agents, in particular, new bitumen-polymer options with high elasticity, strength of the base, and improved performance characteristics. These include:

- cast asphalt

- mastics

- emulsions

- adhesive tape.

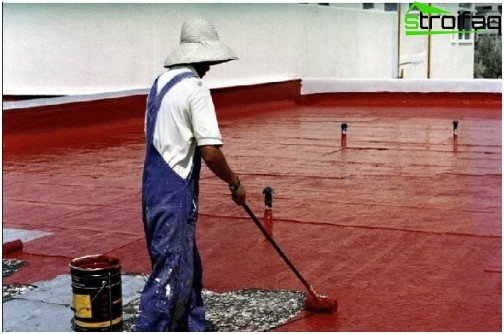

Roofing mastic is applied with a roller or brush. The process is long but worth it

Preparation of the roof for laying (applying) the waterproofing layer

Whatever material you choose for waterproofing the roof, the process of laying (applying) it always starts the same way – from preparing the foundation.

It is best to clean the roof of debris with a compressor – both quickly and efficiently. But here it is important to be careful. It is advisable to install special screens around the perimeter of the roof, which will prevent dust and debris from blowing down. Using a compressor, simply drive the dust into one corner and then remove it with an ordinary broom or a construction vacuum cleaner.

To clean the roof surface at the joints of plates and fasten different equipment (antennas, ventilation shafts, etc.), you need to use hard brushes made of wire or a drill with a brush nozzle. And in order to completely rid the roof of everything superfluous, you can rinse it with a high-pressure car wash. True, after such a procedure, the roof will have to be thoroughly dried..

Important: if the old roll cover is laid on the roof and if you don’t have the opportunity to remove it, it is not recommended to use a sink, as part of the water and debris will necessarily be under the cover, which will affect the quality of the waterproofing layer.

If the waterproofing of the flat roof will be carried out on a concrete base, then cement milk must be removed. The easiest way to do this is by grinding. This method will allow you to remove the top layer of concrete and open its pores, which, after applying the waterproofing, are again clogged.

In addition, it is necessary to check the roof for defects. If you find cracks and crevices, they will have to be cleaned and repaired using a classic cement-sand mortar. Pay attention to the bubbles (if any) – this is a signal that moisture has accumulated under the topcoat and if these bubbles are simply covered with liquid rubber or any rolled material, then the water will not go anywhere, but will be locked inside the “pie”. Over time, the increased pressure will break through the roofing material and you will have to repair again.

Important: before laying the waterproofing layer, it is necessary to treat concrete with a special primer.

Mandatory and laying a layer of vapor barrier, since its absence will cause moisture to the insulation and, as a consequence, its weight. For this purpose, you can use the following materials:

- polypropylene films

- plastic films

- bituminous materials

Types of vapor barrier for roofing

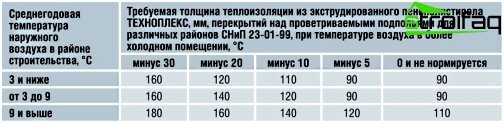

An excellent option can be a vapor barrier for a flat roof techno-nikol. The company’s products are sold in a wide assortment and it will not be difficult to choose the right material, especially since the company has developed tables to select a vapor barrier that make it much easier to choose.

TechnoNikol table for choosing a vapor barrier – the right way to determine the type of vapor barrier material and its thickness

Roofing up

The ramp-up of a flat roof is carried out so that the water does not stagnate on the roof surface, but flows down through special funnels. The angle of the roof is small – from 2 to 4 degrees, but even this will be enough so that moisture does not collect in puddles.

A screed is sloped over the insulation layer, in addition, such a screed will create a solid roof base. Next, the waterproofing layer is laid. However, in some cases, the installation of the waterproofing is possible directly on the insulation. For example, when dense and durable materials, such as polyurethane foam or stone wool, are used as insulation. True, you will have to do without screed, which means that you will need to provide the necessary slope to the slabs of the heat insulator.

Stacking roll surfaced materials

This method, when compared with the classic laying of roofing material, is much more effective and simple. As a waterproofing material, rolled bituminous, bitumen-polymer and bitumen-rubber coatings are used..

Laying a roll-up deposited material on the roof surface. The protagonist is a gas burner

Such materials are very easy to lay on their own. To do this, you need a gas burner and a roll of waterproofing itself. Warming the underside of the material with a burner, it is necessary to gradually unfold it with a stick until the roll or roof runs out. It is necessary to lay strips with a small overlap of 8-10 cm, rolling them with a wooden gurney.

Important: on the seamy side of the roll there is an image that deforms when heated. As soon as you see that the picture has “floated”, you can roll.

One layer of rolled waterproofing material will not be enough, so for reliability you will have to lay another one, and the strips of the second layer should overlap the joints of the first.

Some types of roofs, for example, on buildings made of light prefabricated structures) gluing the first layer of surfaced waterproofing can be difficult. In this case, you will have to fasten the material with mechanical fasteners in increments of 50 cm or more. The second and subsequent layers are fused using a gas burner.

Application of liquid rubber on the roof

The use of liquid rubber for waterproofing the roof is considered the most effective way to protect the roof from moisture and the damaging effects of the environment, since only this method guarantees the safety of the finish coating for 25 years or more. This is a one-piece coating that does not have a single seam..

Application of liquid rubber to the roof using a special spray gun

In addition, liquid rubber is an excellent vapor barrier, so it is advisable to use it if the budget is limited and there are no funds to purchase additional building materials.

Roof waterproofing with liquid rubber is mechanized using a two-channel mixing and dosing spray.

Important: all work on applying liquid rubber should be carried out in dry, calm weather at an air temperature of at least + 5 ° C.

The material is applied to the roof surface evenly in stripes from 1 to 1.5 meters wide. Layer thickness from 3 to 5 mm. And in those places where the liquid rubber will adjoin the weathercocks, drainage systems, parapets, it is necessary to additionally reinforce the waterproofing layer with geotextile or one-component liquid rubber.

Of course, this is not the whole range of roofing waterproofing materials. In fact, there are many more. But liquid rubber and surfaced roll materials are currently the most popular and effective ways to protect the roof from moisture and other troubles..