To build automatic gates with your own hands is not an easy task, requiring certain skills and knowledge. And do not believe those who will assure you otherwise. Nevertheless, making the automatic gate itself is more than realistic. This, in fact, will be discussed in this guide. Want to learn about the varieties and methods of creating automatic gates? Read on!

Content

- Automatic gates – which are?

- Do it yourself automatic swing gates – budget and convenient

- Automation Overview

Automatic gates – which are

The fact that modern automatic gates are incredibly convenient is a thing, no one needs to be convinced. They are in demand, and, of course, the market is full of offers. However, the whole variety of models available is easily divided into three main groups:

- swing automatic gates;

- sliding automatic gates;

- garage automatic gates.

The manufacture of these gates has its own characteristics..

And now – more.

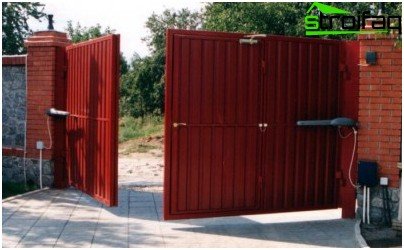

Automatic swing gates for a country house

Do it yourself automatic swing gates – budget and convenient

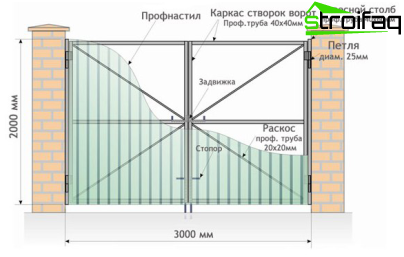

This type of gate is the most familiar and popular because of the convenient and simple device. Prerequisite – clearance for opening the gate.

Basically, the frame for such a gate is made of a profile of high rigidity. Then it is sheathed from above – for example, with wooden or metal panels..

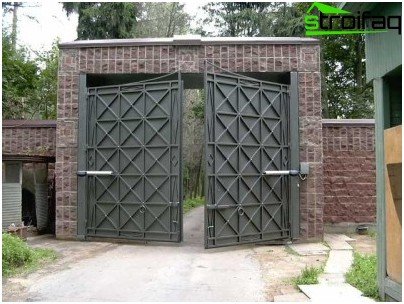

A more expensive option, but certainly very beautiful – forged carved grilles.

Automatic forged sliding gates always look presentable

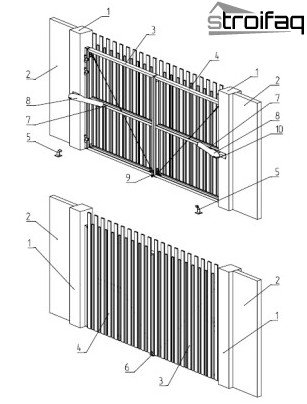

Swing gates – list of components:

- posts for fastening;

- set of loops;

- gate leaves;

- emphasis: lateral and central;

- bolt;

- handles for opening the gate;

- brackets for mounting the electric drive to poles and sashes.

- electric drives (two).

Swing Gates – Anatomy

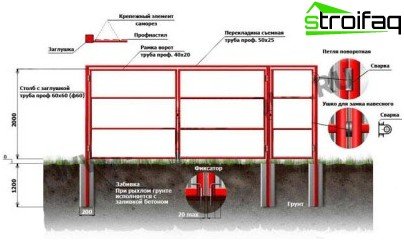

It is convenient to make columns for fastening of gate from a steel pipe. If the gates turn out to be very heavy, it makes sense to install a U-shaped steel frame instead of pillars. This is a guarantee that the gate will not lead over time.

As a supporting structure for installing the base of swing gates (poles or frame), we recommend using a glass-type foundation.

A simple hint for concreting the gate. Pay attention to the pit under the “banquet”

Recently, special hinges are used to strengthen the gate leaves to the posts. They come with bearings. In this case, the gate will be smooth and easy. Usually, the number of hinges installed on the gate is 4 or 6. This depends on the weight of the gate and its size. There are two types of such loops: metal and polymer.

The door leaf (sash) consists of a frame and a filling panel. There are three types of filling:

- sparse;

- solid;

- combined.

The door frame is made of a metal profile (angular and connecting). Filling sections can be made of metal picket fence, sandwich panels, as well as aluminum rolling profile. The metal parts of the doors should be primed and painted..

Sketch of swing gates of metal picket fence with one-sided sheathing: stone pillar support, wall, 3-external frame, 5. side stops, 6. central stop, 7. internal stiffener, 8. linear automatic opening mechanism, 9. lower latch, 10 automatic control unit

Side or center stops are a must. In fact, these are metal stopper pins that do not allow the gate leaves to go beyond the set limits. Stops can be either permanent or removable.

The bolt and handles for opening the gate should also be attributed to the necessary structural elements, because, in case of any power outage, which, alas, is not uncommon, you will have to manually lock and open the gate.

Electric drives and brackets to strengthen them are usually sold as a set. We do not recommend buying them individually, because drives and brackets from different manufacturers may not be suitable for the parameters.

Correct mounting of the lever drive to a brick wall

Automation Overview

Buy a set of door automation today will not be the slightest difficulty. As a rule, the automation kit includes:

- drives are right-hand and left-hand self-locking;

- gate control unit (transformer and control board in one housing);

- set of photocells (receiver and transmitter, remote control, photocells);

- nuts, bolts, bushings and keys for emergency unlocking;

- set of mounting plates.

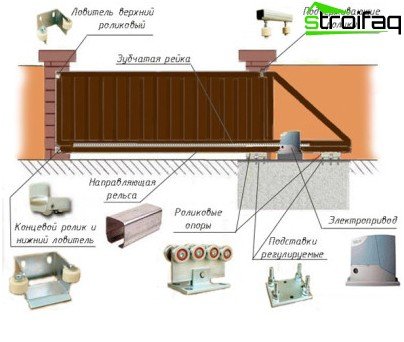

It looks like a set of automation for sliding gates

In order to choose the automatic swing device correctly, it is necessary to take into account several important parameters.

- weight and area of wings;

- opening intensity;

- ease of movement of the gate leaves.

We will consider them in detail..

The weight and area of the gate leaves are parameters that cannot be separated from each other. The reason is as follows. Strong wind loads act on the sash and drive. That is, if we put in automation designed for a leaf weight of up to 100 kg, and do not take into account the area, then the first strong wind will tear an expensive device like a monkey newspaper.

To choose the right device, you need to do simple calculations.

Let’s say that the average wind load in your area is 50 kg / m. If you want to install standard gates from corrugated board with a leaf size of 2×2 m, then the wind load will be 2x2x50 = 200 kg. Now we add the actual weight of one leaf (100 kg) and get the final value equal to 300 kg. In this case, taking into account the margin of safety, it is necessary to install a drive designed for sashes weighing from 400 to 800 kg and for a similar wind load. Then, your gate will last a long time..

Opening Intensity – expressed as the ratio of the time of the actual work in one hour. It is expressed as a percentage. For example, 30% per hour. These data can be found in the data sheet.

Marginal notes: How to apply this parameter correctly? Suppose it takes about 20 seconds to open the gate leaf. The same amount for closing. Total, 40 seconds. Then, we select 30% of 60 (the number of minutes per hour) and get about 18 minutes. Now we only have one thing left – to turn 18 minutes into seconds (1080) and divide this value by 40. We get, as a result, the number 27. Thus, this gate can miss 27 cars in 1 hour. For private home ownership – more than enough. And for a cooperative garage – it’s not enough.

Automatic swing gates for the garage: from the outside it is almost impossible to distinguish from ordinary ones. Automation is visible only from the inside.

The ease of movement of the gate leaves – this parameter depends, first of all, on the correct installation of posts and hinges (without distortions) and on the magnitude of the friction force in the hinges (solved by timely lubrication). In addition, this parameter is affected by weather conditions: frost, snow, icing create additional resistance. Therefore, you should choose a drive with a power reserve. Otherwise, in winter you have to help the gate manually, and this, you see, is not out of a dream.

According to the type of work, automatic devices for swing gates are divided into:

- Linear – these drives are also called “worm” drives. They work on the principle of extension / shortening of the stem, which is driven by a worm gear;

- Lever – the principle of operation of these drives is similar to the principle of the human hand. The long operating lever consists of two parts connected by a movable joint.

Swing gates with linear automatic drives

Linear drives are perfect for swing gates, whose doors open on both sides of the yard. They are easy to operate and relatively inexpensive..

The lever automation allows you to open gates suspended at a distance of 20-40 cm from the edge of the post. This type of automation can be installed on stone columns facing the posts of the gate frame.

As for the brands that manufacture automatic equipment for swing gates, only your preferences and wallet density are important here. For our part, we advise you to pay attention to the products of the Italian company Came Group. This company specializes only in the manufacture of electric drives, and over 30 years of existence in the market, it has learned to do it well.

By the way, Came is the first company to come up with remote control gates.

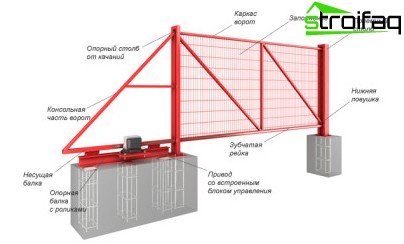

Automatic sliding gates – design and rules for choosing fittings

This type of gate is now the most popular. Yes, when compared with swing gates, the sliding gates will be more difficult due to the need to use special fittings. But in our time, you can buy anything, and this, in the recent past, an expensive and rare structural element, has ceased to be a curiosity.

What are the advantages of sliding gates? There are a lot of them. We will list the most obvious:

- the absence of guides both at the bottom of the doorway and at the top – this removes restrictions on the height of the incoming vehicle;

- accurate operation of automation – this eliminates the need to get out of the car to open the gate;

- unpretentiousness in service.

All you need to make sliding gates is a cheat sheet

It is not difficult for anyone who knows how to handle a grinder and a welding machine to make sliding gates on their own. However, in spite of all its fashion, they have two significant drawbacks: a more “biting” price for automation and the availability of free space to roll back the sash. Otherwise, everything is great – this gate will serve you faithfully for more than a dozen years. On average, the sliding gate operating system is designed for 50,000 open / close cycles.

The choice of material for sewing sliding gates depends entirely on your imagination. It could be:

- corrugated board;

- metal picket;

- wood;

- forging;

- a metal sheet;

- polycarbonate.

Polycarbonate gates look very modern

By type of construction, these gates are divided into 2 types:

- with a solid canvas;

- with integrated gate.

Set of accessories for sliding gates consists of

- roller carriages;

- top support rollers;

- rolling rollers;

- 2 catchers – upper and lower;

- guide profile;

- rubber plugs.

Note: The price of the hardware kit depends on the weight of the gate, the length of the rail and the manufacturer. For example, for gates up to 400 kg with a guide of 5 m, the set of accessories of our production will cost, on average, 5,700-6,000 r. A similar set for gates up to 800 kg will cost 2,500-3,000 r more. A set of overseas accessories of good quality, for example, the Rolling Center (Italy) will ease your wallet by 20 or more thousand rubles.

In a word, “think for yourself, decide for yourself”.

An interesting option for door trim: forging + polycarbonate

Making sliding gates with our own hands – step by step instructions

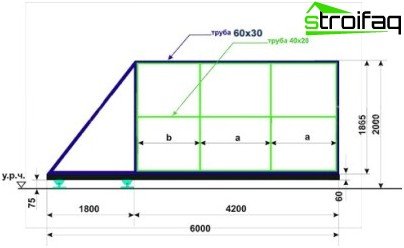

Step No. 1 Determine the size of the gate. The length, width and height of the movable leaf determines the weight of the gate, and, therefore, the choice of fittings. The size of the gate also determines the distance required to move the leaf. Ideally, it should be one and a half times larger than the opening of the gate.

Step No. 2 Install the support posts. As a material suitable:

- steel profile pipe;

- oak timber;

- channel;

- concrete or brick post.

The main rule during installation – the support posts must be deepened into the ground by 1 meter. Otherwise, in the coming winter or spring, the support pillar may shift vertically and spoil the entire geometry of the frame. And this will negatively affect the opening of the gate.

It looks like a “bench” in the assembly before pouring concrete into the foundation

To install the column correctly, do the following:

- dig a hole about 120 cm deep;

- on the bottom we lay a “pillow” – a bed of sand and gravel 15 cm thick, we compact it well;

- install the pillar and fill it with concrete (cement grade not less than M-300).

Step number 3 We make the foundation for the gate. This is the basis of the whole structure. Firstly, the foundation holds the weight of the gate, and he, you see, is not small. Secondly, a “bench” is laid in the foundation – a channel on which the gate leaf will move on casters.

To lay the foundation, do the following:

- Dig and arrange a foundation pit.

Parameters:

- length = 50% of the size of the doorway.

- width (cm) – 40-45;

- depth (cm) – 100-120.

The shape of the pit is U-shaped, as shown in the figure. After the pit is ready, you need to do the filling. The size of the “pillow” – as when installing the pillars.

- To make a “banquet”. A channel (width 20 cm) and metal fittings (cross-section 10-12 mm) are required. The fittings must be cut into “swords” 100 cm long, then welded to the channel shelves;

- Install a “bench” and pour concrete.

Important!

- After pouring concrete needs to settle. The minimum time for curing is 6-7 days.

- The top of the “banquet” is set flush with the road (ie, at the same level).

- To avoid cracking, concrete should be watered daily..

In this sketch, the depth of laying the metal supports is clearly visible – 120 mm. This value may vary for regions with a high freezing rate.

Step No. 4 Production of the supporting frame. It is convenient to make the frame for sliding gates from a profile steel pipe (the so-called profile for gates).

Manufacturing steps:

- cutting the profile to the desired lengths of segments;

- removal of rust from the pipe (you will need a grinder with a “metal brush” nozzle);

- degreasing the pipe with solvent or gasoline, applying anti-corrosion soil;

- assembly of the frame by welding;

- welding seams and anti-corrosion primer for the entire frame.

Helpful hints:

- For the external contour of the frame, select a professional pipe with a section of 50×50 mm or 60×40 mm.

- For stiffening ribs, a pipe of 20×30 mm or 30×40 mm is suitable.

- We collect the elements of the guide and the frame in a checkerboard pattern, because, from heating, the door leaf will definitely lead.

Material distribution for the manufacture of sliding door frames

Step number 5. Frame painting and door leaf stitching.

Coloring can be applied immediately after drying. An inexpensive and practical option is alkyd enamel. To make the gate look richer, we recommend applying at least 2 layers of paint. After applying each coat of paint, it should dry.

The choice of sewing material – a purely individual matter.

The material should be fastened to the inner pipes (frame stiffeners). For assembly we use self-tapping screws or rivets.

Scheme of convenient and inexpensive sliding gates made of metal

Step number 6. Gate mounting.

Installation is carried out in the following order:

- install the rollers on the “bench” and fill them into the guide of the door leaf;

- we set the gates strictly according to the level (you can use both the usual two-meter level and the laser one);

- grab the lower roller trolleys to the channel by welding;

- weld the upper rollers (supporting and trailer);

- weld the lower and upper catchers to the supporting posts;

- install automation;

- experience the gates, boast to neighbors and be proud of ourselves!

Such gates will cost you one and a half to two times cheaper than the “store”.

Layout of classic swing gates with brick pillars

Garage automatic gates – briefly on the main thing

Usually four types of gates are installed in garages:

- classic swing;

- sectional folding (with the help of spring systems and guides rise up);

- lifting and swiveling;

- rolling.

Sectional automatic garage doors: inside view

The first three types are best suited for self-production..

It’s problematic to make rolling shutters with your own hands, because they consist of many slats that are made only in industrial conditions.

Swing garage doors are built on the same principle as external. For the manufacture of sectional doors, you will need a lot of parts that you have to buy in the store: canvases, guides, shafts, hinges, suspension balancing springs, etc. Therefore, it is better to order such gates in the finished version – it is more reliable and, oddly enough, more economical.

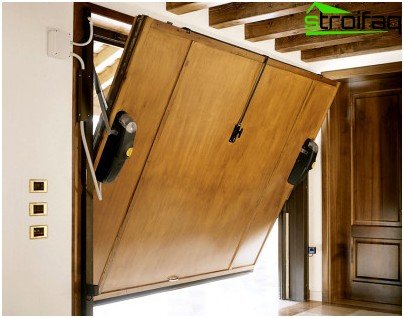

Lift-up garage doors – note: in this example, the automation is mounted correctly

Lift-and-swing gates consist of an external frame, a solid canvas and automation, which raises the canvas up to the “ceiling”. These are very simple and effective gates, the main disadvantage of which is expensive automation.

Our verdict: if you really want to make automatic garage doors yourself, reliably and inexpensively, pay attention to the classics. Go for it!