Polyfoam as a heater

Polyfoam is an environmentally friendly material that can provide effective thermal insulation, high fire safety and thereby bring significant economic benefits in the construction of buildings and structures, as well as in their further operation. The polymer material foam is close in structure to natural materials: microscopic cells (like a cork tree) are filled with gas or air. It is this structure that gives excellent heat-insulating properties to this material, which is why polystyrene as a heater has received well-deserved recognition all over the world. The use of foam in the construction of houses as a heater is one of the cheapest ways to achieve good thermal insulation.

Content

- Properties and characteristics of the foam

- The use of foam as a heater

- Wall insulation: inside and out

- Foam floor insulation

- Roofing insulation

- Protecting the foundation from the cold

- Foam insulation for communications

- Thermal insulation of refrigerators

Properties and characteristics of the foam

The main properties of the foam characterize its features, as well as advantages over other materials:

- Ecological purity and harmlessness – are regulated by the hygienic conclusions of manufacturers and the state standard.

- Low thermal conductivity. By this indicator, as well as by vapor barrier foam, today there are no equal. The material consists of 98% of air, and it is known to be the best natural heat insulator.

- Stability and fire safety in a wide temperature range. Its physical and chemical properties do not change with changing ambient temperature. Polyfoam fireproof material. It belongs to the group of plastics that emit during combustion, as well as wood, carbon dioxide and water. But high-quality foam does not support combustion: the flame retardant contained in it gives the material a self-extinguishing property.

- Low dynamic stiffness, which provides good sound insulation.

- Resistance to various technical environments, as well as to microorganisms. The material does not emit water-soluble substances, does not decompose, therefore, if it enters the soil or groundwater, it does not have a detrimental effect on natural resources.

It’s important to know! The foam used in construction must be protected from interaction with chemical compounds – alcohol, turpentine, paint thinner, acetone, kerosene, gasoline, various resins, which can completely dissolve the foam and damage its cellular structure.

- Resistance to biological factors. Polyfoam is not a nutrient medium for bacteria and mold fungi, therefore their appearance on it is excluded.

- Light weight. Due to the minimum density, polystyrene almost does not affect the change in the load on the foundation and supporting structures.

- Cheapness.

- Easy handling and easy installation.

- Durability. It has an almost unlimited service life..

The use of foam as a heater

Thanks to the combination of all of the above properties and, primarily, low thermal conductivity, the use of foam in construction allows you to:

- firstly, to reduce the cost of heating the building during operation;

- secondly, to save usable space;

- thirdly, to reduce the cost of loading and unloading;

- fourthly, to reduce the cost of using complex mechanisms and tools during processing;

- fifthly – to reduce the time for construction work, while receiving a warm and comfortable building.

It’s important to know! Polyfoam combines well with many materials, such as cement, lime, gypsum, foam paints, asphalt, roofing felt, artificial fertilizers, caustic soda, soap.

Polyfoam has been widely used in the construction of underfloor heating, as well as thermal insulation of foundations, walls and roofs. This material is also actively used for thermal insulation of pipes, cables, ventilation ducts and other underground utilities..

Polyfoam has become indispensable in the production of refrigeration and freezing equipment and in the design of low-temperature warehouses.

Wall insulation: inside and out

Wall insulation with foam is the most effective and economical way

Recently, there has been an increasing popularization of wall insulation with foam. This is primarily due to the constant rise in energy costs, and, as you know, wall insulation with foam allows reducing heating costs by up to 50%. At the same time, in the heat in the house you will feel cool and there will be no need to turn on the air conditioner often.

Polyfoam is used for internal and external wall insulation. On the outside, the boards are glued with cement mortar, glue or mastic, or are fastened using mounting devices. Foam plastic is protected from possible exposure to open flames by various non-combustible materials: brick, ceramic tile, aluminum or steel profile, plasters.

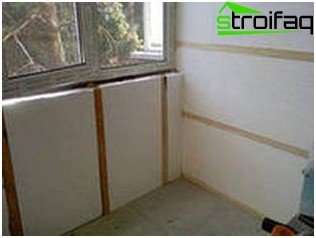

In the inner side of the premises, the foam also exhibits its soundproofing properties. And in these cases it must be protected from open flame. This is done using plasterboard sheets or regular plaster..

Exterior wall insulation with foam – high quality, efficient, affordable

Plates for external fastening should have a thickness of 50 mm, and for internal enough 30 mm. When attaching the foam plates from the outside of the walls, their surface is plastered with cement mortar, using a metal mesh.

Thermal insulation of the floor with polystyrene with laying lag and flooring after finishing coating

Foam floor insulation

When insulating the floor, polystyrene is an effective heat-insulating agent that also reduces the transmission of shock noise (movable furniture, steps, etc.). 50 mm thick foam slabs are usually laid on a layer of insulating material. After sealing the joints, a concrete or sand-cement mixture or a wood chipboard sheet pile with a thickness of at least six cm is laid on top.

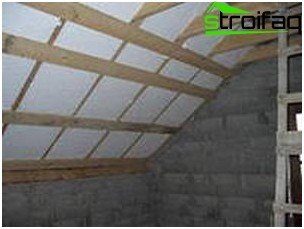

Styrofoam roof insulation – ventilated version

Roofing insulation

Thermal insulation with foam plastic roofs of apartment buildings and communal buildings is carried out in several ways. One of them is the “Unventilated (warm) roof”. In this case, the roof is covered with 70 mm thick foam slabs, flooded with a waterproof bitumen layer. The second method is “Ventilated (cold) roof”, when the foam boards are installed on the back of the roof, leaving a vented cavity to prevent condensation of water vapor. Good thermal insulation of the roof is especially important when installing a living room in the attic.

Thermal insulation of the foundation with polystyrene foam is an operational reliable way to reduce heat loss

Protecting the foundation from the cold

It is no secret that the foundation of the building is the foundation, and the thermal comfort and durability of the house depend largely on it. Therefore, the thermal insulation of the foundation, especially in latitudes with severe winters, plays a paramount role in the construction of buildings. Polyfoam is traditionally used as the middle layer of three-layer foundation blocks. Styrofoam proved to be no worse as a heater (the best reviews about it) when erecting basements: insulation boards are laid in one or several layers on a prepared site and poured with concrete.

Next, the structure is erected in the usual manner. In this situation, the concrete screed serves both as a foundation and as the base of the floor. Polyfoam is also used for external insulation of the foundation to prevent freezing of the soil. To do this, dig a trench 1 m wide along the foundation, lay thermal insulation plates and fall asleep.

Foam insulation for communications

Until recently, thermal insulation of utilities did not receive due attention, although heat losses through them make up about 30%. Recently, foam plastic has been increasingly used to insulate water supply pipelines, telephone lines, ventilation ducts, buried cables. Thanks to this excellent material, pipelines can now be laid at a shallower depth, reducing a lot of excavated soil. In this case, the ability to give the foam almost any desired shape plays a special role, adapting it to the design requirements.

Thermal insulation of refrigerators

Polyfoam is used in the construction of refrigerated rooms, in the construction of shop windows, freezers, refrigerated storage facilities, refrigerated wagons. In this case, not only its thermal conductivity coefficient is taken into account, but also its moisture absorption. According to these two indicators, the foam plastic surpasses all existing heat-insulating materials previously used in refrigeration equipment, for example, mipora and expandite, which absorb moisture gradually, and this reduces the efficiency of insulation. Polyfoam is devoid of these shortcomings – the water absorption of the plates is not more than 3%. In addition, its insulating properties do not deteriorate over time, and the service life reaches 100 years. That is why it is foam plastic that is used for thermal insulation of ceilings, walls, partitions of refrigerated rooms.

The use of polystyrene for thermal insulation of walls, roofs, ceilings, floors in houses, as well as utilities and refrigeration facilities is determined by its special physical and technical properties. There is no doubt that in terms of price / quality ratio polystyrene is the best insulation. Houses insulated with polystyrene foam will last for many years to their master.