Concrete floor painting

As a rule, they prefer not to paint concrete surfaces, and in particular the floor, but leave them in their original form. But even such a durable material is prone to chips, mechanical damage, as well as chemical attack. Therefore, painting a concrete floor is not just a work to improve a room, but, first of all, a way of protection. That’s just how to paint concrete and whether to do it at all? Let’s try to figure this out..

Content

- Epoxy paint: advantages, disadvantages

- Characteristics of acrylic dye

- Polyurethane enamel for concrete floor

- Primer as a protection

- What attract polyurethane compounds

- Epoxy Primer Benefits

Epoxy paint: advantages, disadvantages

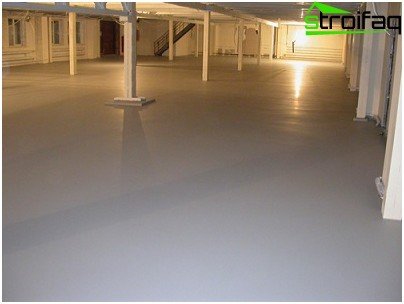

Concrete floor epoxy paint is a super strong and durable coating that allows you to extend the life of the concrete floor and gives it a presentable look. Such paint is quite resistant to various external influences and is able to withstand high loads. In addition, the epoxy does not wear out even on the condition that it will cover the floor in production shops, hangars, car repair shops, stairs and parking lots.

It can be used not only indoors, but also in open areas, since epoxy paint is resistant to adverse weather conditions. Another advantage of this paint is the fact that it can be applied directly to fresh concrete, which has not dried out enough, thereby improving the quality of the substrate.

Advantages of epoxy paint:

- does not turn yellow over time

- has high waterproofing properties

- perfectly adheres to concrete surface

- resistant to various chemicals – acids, alkalis, fuels and lubricants, salt solutions

- environmental friendliness.

Disadvantages:

- two-component – before using epoxy paint you will have to mix it

- some problems with repeated staining are possible. If you decide to change the color of the floor to another, then it will be quite difficult to do.

It is recommended to apply epoxy paint in two thin layers, the curing time of which is from 12 to 24 hours.

Epoxy paint for concrete (bulk floor) is applicable only indoors

Characteristics of acrylic dye

Acrylic paint for concrete surfaces is an aqueous composition based on acrylic resins with the addition of various polymers.

This paint prevents the destruction of the concrete floor, creates a protective polymer film that prevents various chemical and mechanical influences. The coating formed by acrylic paint is reliable and quite durable, so you can safely paint the floors in garages, basements, balconies, stairs, etc..

Advantages of acrylic paint for concrete surfaces:

- reliable protection of concrete against corrosion

- increased weather resistance

- environmental friendliness

- simplicity and ease of application

- drying speed

- moisture resistance and water resistance.

You can apply acrylic paint to concrete with a brush, a roller, and a spray, and unlike an epoxy one layer will be enough, although for more certainty you can cover the floor with two layers of paint – it won’t be worse.

The process of painting concrete with a roller

Acrylic paint is used for finishing floors in utility rooms and industrial premises.

Drying time – 12-14 hours.

Polyurethane enamel for concrete floor

As a rule, polyurethane enamels are two-component, however this in no way detracts from their high qualities. They are intended for finishing concrete both indoors and outdoors..

Paint Benefits:

- high weather resistance

- profitability

- environmental friendliness

- high hiding power

- excellent mechanical and chemical strength

- can be used for painting wooden and metal surfaces, as well as asphalt

- forms a perfectly smooth glossy surface

Disadvantages:

- long drying time

It is possible to apply polyurethane enamel at a minimum temperature of + 5 ° C and a relative humidity of not more than 75%. Since the paint is two-component, first you need to thoroughly mix the first component, and then add the second to it. After the re-mixing procedure, the paint is ready for use..

It is advisable to paint the floor in two stages: the first is to apply a thin uniform layer of paint, avoiding smudges and spills, and the second to apply the paint again, but no later than 24 hours after the first painting.

Polyurethane enamel is recommended to be applied in two stages, between which you need to withstand a technological break.

Drying time of polyurethane paint – from 2 to 14 days. such a large spread in time is explained by the following points: after 2 days the paint does not stick and it is quite possible to walk on it, after 7 days the floor covering acquires the final mechanical resistance, and after 14 days – the chemical.

Primer as a protection

If you do not have funds for painting a concrete floor, then you can simply primer it. The primer can be used as the only protective coating, as well as for pre-treatment of the surface before applying the top paint on it.

Primers for concrete are of two types:

- polyurethane primer

- epoxy primer

What attract polyurethane compounds

Polyurethane primer provides reliable filling of small pores, hardening and dust removal of concrete, as well as high adhesion to the surface. This product is resistant to gasoline, chemicals, detergents, oils, fats and precipitation..

Benefits:

- simplicity and ease of application – with a brush or roller

- reduces finish coverage

- improves the adhesion of the finish layer

- cured by moisture in the air

Judging by the name, it can be concluded that such a primer is used before staining with polyurethane enamels. This is true, because their compositions are almost identical.

Before applying a primer to a concrete floor, it must be thoroughly cleaned of debris and dust, and also ensure its dryness.

The primer is applied with a short-pile fur roller or brush with a thin layer. At the same time, try to prevent spills and smudges so that the surface looks homogeneous. If the soil is not evenly absorbed, you can repeat the procedure.

If you decide to use the paint, then it can be applied only 12 hours after the completion of priming the floor.

Natural beauty of polyurethane primed concrete

Epoxy Primer Benefits

Epoxy primer is designed to treat concrete surfaces before applying epoxy paint to them. But you can use it as an independent coating.

Such a primer ensures reliable closure of all cells and pores in concrete, as well as dedusts and hardens the floor surface..

Benefits:

- water resistant

- waterproof

- improves adhesion of the topcoat

- makes the surface more durable

- resistant to chemicals and mechanical wear

- water resistant

Luxurious glossy gloss epoxy primer

In addition to concrete, an epoxy primer is ideal for treating metal and ceramic surfaces, and in general, it is indispensable for those substrates that have low absorption.

Before applying epoxy primer, the concrete surface must be sanded and dust and debris removed. The base must be perfectly clean and dry..

Apply the soil with a rubber spatula or roller with a not too long pile. The main thing here is to hurry, as the material will lose its quality within 20-30 minutes, so do not waste time, but act.

Decided on the choice of protective and decorative composition? It remains only to choose the appropriate coloring of the coating, combining with interior design or landscape design.

To summarize: there are not so few various means for protecting a concrete floor, but the choice is still yours. Of course, you can generally refuse from any manipulations, just keep in mind that untreated concrete begins to crumble quickly enough, and various stains from gasoline, oil and other substances appear on its surface (especially in the garage). Whereas a painted concrete floor is able to please you for many years with its pleasant glossy gloss and cleanliness..