Secrets of the proper installation of suspended ceilings

Installation of suspended ceilings is a good solution for urban apartments (especially with low ceilings). They will help create a feeling of airiness, volume of space, while hiding the flaws and defects of the old ceiling, protect it from leaks and noise from the upper floors. And all this – without garbage and dust. In addition, these designs look very impressive. You can choose from more than 300 of their color shades – with the effects of a mirror, fabric, wood, marble, velvet, Venetian plaster, with a simple smooth matte surface.

Content

- Overview of materials and mounting methods

- What else to know about PVC

- Technology for installing suspended ceilings

- Tips, practical advice

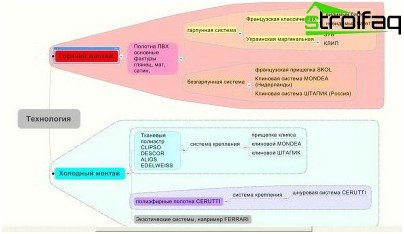

Overview of materials and mounting methods

Stretch ceilings vary in material of manufacture and method of attachment.

If we talk about the material of the canvas, then emit:

- from polyester fabric, which is specially impregnated with polyurethane. This class includes all CLIPSO ceilings;

- polyvinyl chloride ceilings that are cadmium free and soft enough (all other ceilings).

A variety of pvc films for suspended ceilings

Depending on how the frame is fixed, emit:

1. Harpoon stretch ceilings

On all sides of the ceiling, a border made of fairly rigid PVC is stretched and welded. If you look at it in cross section, it resembles the shape of a harpoon-hook. Hence the name of this method of attachment. This type includes ceilings of long-known brands, for example, EXTENZO, BARRISOL, NEWMAT, CARRE NOIR, NOVELUM. Recently, this list was supplemented by several brands that appeared on the market in Russia, such as DPS, DECKENFEST, DECOMAT.

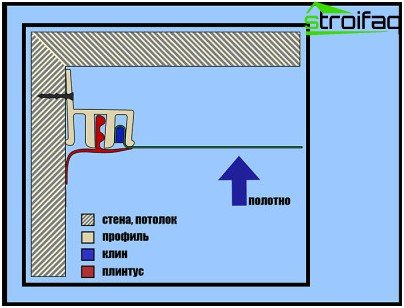

Scheme of installation and fastening of suspended ceilings

2. Non-harpoon stretch ceilings

They are divided into several subclass categories. For example, MONDEA ceilings from the Netherlands are wedged. In this case, the edges of the web are heated and straightened, then they are clamped using a special spacer profile. This method is somewhat similar to the embroidery process on the hoop. When a PVC film is attached to two semicircular surfaces. These mounting “cams” are included in the mounting profile, so this method is called the cam method. When the film is pushed with a spatula, these “cams” diverge, and when they try to stretch it back, they automatically compress. This method is used to mount SKOL and PRESTIGE DESIGN ceilings.

The mounting profile that is used with this method has a real opportunity to reduce the loss of ceiling height by 8 mm. CLIPSO French polyester ceilings are secured with a flexible cord.

The scheme of fastening and suspension of the ceiling structure according to the harpoonless technology

What else to know about PVC

A fairly large number of requirements are imposed on a stretch ceiling. Which include:

- its durability, lack of smell, safety for ecology and ease;

- It is also very important that the material used can be painted seamlessly in any color. The polyvinyl chloride film and polyester fabric meet all these requirements in the best possible way..

You also need to know (about PVC) that

- polyvinyl chloride film has a weight of from 180 to 320 g / sq. m, and the thickness usually does not exceed 0.35 mm;

- weighted average sound absorption coefficient – not more than 0.4;

- the pressure that the film can withstand reaches 1000 Pa;

- tensile strength reaches a limit of 30 N equally in the longitudinal and transverse directions;

- elongation to break reaches 220%;

- light absorption coefficient depends on the type of ceiling. If the ceilings are “varnish”, then the coefficient is 30%, and if “velvet”, then 95%;

- such a film is waterproof and fireproof;

- depending on the temperature, it can change its physical properties. For example, if you lower the temperature below 0 degrees Celsius, then it becomes fragile and hard. However, if the temperature is raised again, it will still be flexible and elastic. If the film is kept at a temperature of less than 40 degrees Celsius, it begins to collapse;

- PVC film is quite stable in heat and can withstand temperature, while maintaining its properties, up to 90 degrees Celsius;

- this material is remarkably stained, and the color scheme has up to 100 shades;

- the surface of the film can also be almost anything: from matte with shallow embossing and without it, with the effect of leather, marble, wood, metal, with holes, with the effect of satin fabric or a glossy surface. In general, the presence of a variety of color solutions depends on the brand of the canvas;

- the film can be from 1.3 meters to 2.2 meters wide, depending on the nature and characteristics of the production;

- due to the fact that it is easy to weld, it is very simple to make cloths with a width even up to 6 or 8 m. At the same time, practically no seams are visible. More than 8 m of canvas is not recommended. Otherwise, sagging of the canvas in the middle part cannot be avoided.

The advantage of a ceiling made of polyester fabric is stability, no deformation and sagging

About polyester fabric you need to know that it:

- thinner and lighter than PVC. Its weight does not exceed 200g / sq.m, and its thickness is not more than 0.25 mm;

- The advantage of this material is that it is impregnated with a special composition, due to which the dimensions of the fabric cloth are more stable than that of the film;

- tissue elasticity is maintained even at a temperature of minus 30 degrees Celsius;

- Usually the canvas is made 4 m wide, but by a special order it is possible to produce a five-meter canvas. And even in this case there will be no seam on the ceiling;

- polyurethane is not subjected to the welding process, so if there is a need to make the canvas wider than the standard, then it is usually sewn or pieces of material are joined using a special profile;

- The main disadvantage of polyester fabric is that it must not be dyed until installation. Typically, such a ceiling is left matte white or painted after completion of all installation work, for example, a drawing is applied or the entire surface is simply tinted;

- there is also no way to select the texture of the ceiling surface.

Technology for installing suspended ceilings

Stretch ceilings of various types have their own characteristics and subtleties of installation technology.

1. First of all, the company’s specialists who install the ceiling take measurements.

2. Then the canvas is brought to the object (this usually happens within 1 to 30 days).

3. At the same time, at the facility itself by this time it is necessary:

- in those places where the ceilings will be attached, the walls should be strong, be in the same plane, straight and intact;

- all finishing materials, such as drywall, ceramic tiles, etc., must be very securely fixed;

- if it is supposed to install a ceiling molding, then the ceiling itself should be in the same plane.

- to finish all construction work, all garbage should be cleaned, cable lines are brought to the places of installation of the lamps, which provide switching on and off the voltage;

- the room must necessarily be heated during operation of the ceiling and maintain a certain temperature regime at the time of its installation; If all these conditions are met, installation of the ceiling begins.

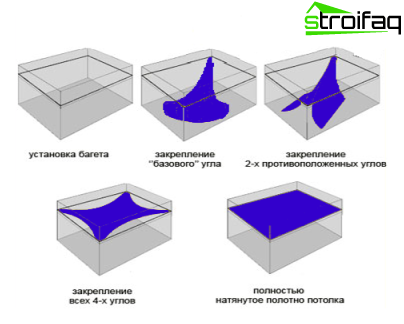

The main stages of work

- First, a hydraulic level and a painting cord are planned on the base ceiling and walls of the attachment point.

- Next, the canvas in the package is heated with a heat gun and gradually straightened.

- Then, using special clip-on clips, the canvas is attached to the baguette..

- With the help of a special spatula, the first – the so-called “red” corner of this canvas, is stuffed with a harpoon into a baguette.

- Then, diagonally, the fabric is heated to 70 degrees Celsius and the soft film is already stretched.

- Next, a harpoon is brought into the groove of the ceiling profile in the opposite corner.

- The whole procedure is done with each diagonal and on all sides of the edging..

- After the film has cooled, it is already firmly connected to the fasteners around the perimeter.

Installation of suspended ceilings: a standard sequence of technological steps

Wedge Installation

- If the ceiling is installed in a wedge manner, then the exact dimensions and calculations are not so important. You need to know the width and length of the room, because the canvas itself should be wider than the distance between the walls by about 10 – 15 cm.

- They always make a rectangular canvas, and fitting is carried out directly in the room itself.

- In a special profile, which can be mounted on the walls and on the ceiling, the previously hung canvas is fixed using special plastic wedges.

- Excess sheets that may protrude from under the mounting profile are trimmed, and the jamming points are covered with a special decorative strip that resembles an elegant skirting board. It has a flexible, sealed part that snaps into the profile, so that the canvas fits snugly against the wall.

If you strictly follow the entire sequence during the installation of the ceiling, then there will be no wrinkles and straightness of the seams.

This method of installing the ceiling is much more complicated than the harpoon, and it is also more difficult to dismantle it. But it has a number of undeniable advantages..

- For example, if you need to make the ceiling a single canvas, and the area at the same time exceeds 100 square meters, then this is the only option, since it is possible to adjust the degree of tension.

- Also, if there are difficulties with the accuracy of determining the size of the room, or changes in the dimensions of the ceiling are expected, which also makes it difficult to indicate certain parameters, this method is perfect.

- When fastening occurs in the cam way or using a flexible cord, the whole process is quite similar to the wedge method. The difference is only in the fasteners themselves. And the canvases are also made with a margin, and during the installation process they are sized.

Classification of structures of suspended ceilings by methods of fastening and materials of paintings

Tips, practical advice

- Depending on the material and technology of the installation of the ceiling, sagging is possible, which forces to limit the size of the ceiling, and the size of the allowable sagging does not exceed 1% of the length of the diagonal of the canvas. In other words, if the canvas has dimensions of 5 * 6 m, then the edges can be only 4 cm higher than the center. But if an additional support is installed in the place of the chandelier, the center sags even less.

- Several canvases are made if the ceiling is supposed to be multi-level, the area of cam and harpoon ceilings is more than 50 m2, and for wedges more than 120 m2. An intermediate support is made, to which individual canvases are attached using a special profile.

- But the most difficult in terms of labor is a three-dimensional or 3D ceiling. First, the frame is designed. Then it is ordered from individual parts of the aluminum profile. Then such a frame is installed in the lower part of the walls and floors. Initially, this design is somewhat reminiscent of an openwork bridge. The process and manufacturing technology of individual paintings in this case is much more complicated and takes longer than when installing a flat ceiling.

- To prevent the accumulation of moisture and condensation between the old ceiling and the canvas, ventilation holes are made in the profile. Ideally, you need to install ventilation grilles in the canvas. Thus, a forced exhaust will always occur. And if the area of the room is more than 35 square meters. m., then such a measure is simply necessary.

- When installing a stretch ceiling, you can use halogen lamps, fluorescent lamps or conventional incandescent lamps. When installing fixtures in the ceiling, it is necessary to limit their power. For example, for ordinary and fluorescent lamps, the power should not be higher than 60 W, for halogen not higher than 20 – 35 W.

- You must also comply with certain requirements when installing fixtures on 12 W. There is a need to use special transformers, otherwise the ceiling may sag due to the increased softness of the PVC film.

- There are various options for mounting high power lamps, which are used in the process. To limit heat transfer, it is necessary to provide a distance between the lamp and the ceiling of at least 1 mm. If transformers are used, then they are mounted in the lower plane of the structure, and then you need to lower the mounting profile by 5 – 7 cm.

- The company that installs the ceiling usually gives a guarantee for its work for a period of up to 10 years, provided that the temperature regime is maintained within the range of 0 – 50 degrees Celsius. The warranty covers the preservation of color, the absence of cracks, wrinkles and sagging canvas. Even if the ceiling was flooded from above with water or it was accidentally pierced.

The fastening of the stretch ceiling canvas begins from the corner of the room

If you follow all the technologies according to the instructions, then you have every chance to mount the suspended ceiling correctly, without defects. Pay particular attention to the selection of quality certified material..