Pumps for wells

Pumps for wells – devices designed to lift water from great depths. As the name implies, pumps of this type are installed directly in the drilled well, and due to the significant degree of immersion, they got a second name – deep ones. Submersible pumps for wells are needed to provide water for private houses, housing and communal services, enterprises, industrial buildings, as well as for irrigation and irrigation of household plots. A feature of such pumps is their compact size, which allows the transportation of water even from the narrowest wells, an acceptable level of pressure and a long service life.

- Types and principles of operation of borehole pumps

- Submersible pumping equipment

- Surface pumps for wells

- Manual control units

Types and principles of operation of borehole pumps

The classification of deep pumps is extensive: each type has its own characteristics.

Submersible pumping equipment

Used to lift water from any tanks. Unlike other varieties, the submersible pump is located directly in the water. This indicates the need for manufacturing to use high-quality materials that can effectively resist corrosion. According to the principle of action, the units are divided into vibrational and centrifugal.

Vibration class

To date, they are the most economical option. In addition to an affordable price, vibration-type pumps are attractive due to their simple design and low maintenance. This type of pumping equipment is devoid of bearings and rotating elements – the most vulnerable parts of any mechanism that require constant monitoring of engine operation and lubrication. The absence of rotating parts not only reduces the heating of the device, but also prevents premature wear.

Vibration pump – the most economical solution

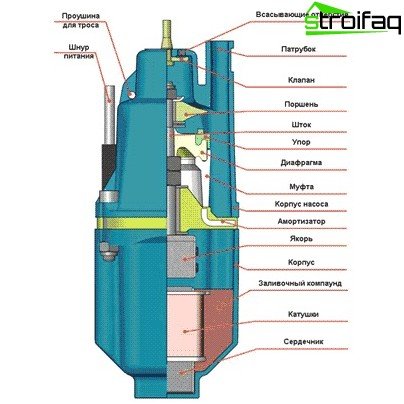

The principle of operation is simple. It is based on creating a magnetic space when passing through an electricity coil. When the current affects the coil of the coil, a magnetic region is formed that draws in a core connected to a rod, which in turn is connected to a diaphragm made of rubber.

The diaphragm bends, creates a reduced pressure in the pump chamber. Water enters the chamber, then – the turn of the springs. The diaphragm returns to its original position, creating excessive pressure blocking the valve. Water flows to the consumer through the outlet pipe.

Vibration pump device

Submersible vibration pump is an ideal device for pumping water from different containers, irrigating vegetable gardens and gardens, for pumping water from flooded basements and organizing water supply for industrial and residential buildings.

Well centrifugal pumps

A common class of equipment with which you can pump different liquids: cold and hot water, acid and oil solutions. A centrifugal pump consists of an engine on the shaft of which an impeller is mounted with holes for outflow and water supply. The principle of operation is based on the transfer of energy of a rotating wheel, a fluid that is located between the blades. Centrifugal force draws fluid into the housing and creates a pressure difference. In this case, the pump runs continuously, supplying water through the outlet pipe.

Centrifugal Pump – High Pressure Capability at Standard Discharge

Centrifugal pumps are self-priming and normal-suction, each of which is divided into single and multi-stage. Self-priming pumps have a horizontal housing. They begin to work when the suction pipe is completely filled with air. On the other hand, a normally suction pump must be filled with water before switching on. Multistage from single-stage differ in the ability to develop high pressure, while the performance remains the same.

Surface pumps for wells

Such equipment will make it easy to provide a cottage or a country house with drinking water. It is irreplaceable during irrigation of personal territories.

It is important! Surface pumps are not designed to handle even the smallest degree of water..

The surface pump is not immersed in a well or in a well; only a flexible hose is introduced into the source

The pump stays on surface during operation. Only a hose descends into the water. The suction depth is 9 meters, but you can additionally purchase ejectors to increase this indicator. Before operation, the surface pump must be filled with water. Models with an automatic start and shutdown system are recognized as more profitable, because consume little energy, are protected from overheating and pump water much better.

Manual control units

Pumps are used to supply and transport liquids without abrasive components, as well as media such as alcohol, edible oils, paraffin, fuel.

It is important! The use of a hand pump for pumping ether or carbon dioxide is not permissible. The temperature of the pumped solution should not exceed +80 degrees.

A manual pump for a well has a suction height of up to 9 meters (if there is a check valve at the end of the water supply). These pumps are ideal for filling pipelines of pumping units of impressive dimensions before switching on. The hand pump consists of a body, a cover, a wing, a suction part, a lever, 4 valves and a shaft. The principle of operation is to rotate the wing using a hand lever so that each side is involved in the suction or displacement process, ensuring continuous fluid movement.

Hand pump pumps liquid with different degrees of pollution and with different density

There are a large number of hand pumps that differ in appearance, technical characteristics and scope. Some are designed to work only with oils and fuels, others – with contaminated water.

Which pump is best for the well?

Have decided install a pump for a well or wells, but don’t know which model is right for you? Probably the majority, trying to solve the problem, first sit down at the computer and try to find the answer on the Internet. Of course, the query “pumps for wells: reviews” may clarify a difficult situation somewhat, but virtual information is clearly not enough for a reliable answer to a pressing question.

Selection options

So, when choosing a pump, you need to pay attention to some points:

1. The mark of the bottom of the borehole bottom. This information can be obtained from the passport issued by the drilling company..

2. Dynamic water level. An important characteristic that reflects downhole production. The dynamic level is a segment from the earth’s surface to the water mirror during pump operation. The flow rate is the maximum amount of fluid that the well produces per unit of time..

It is important! If a significant amount of water remains over the pump unit after its operation for half an hour, then the flow rate is not bad.

3. The static water level is the distance from the ground to the surface of the water. Before measuring the well should not be pumped out for some time. Subtract the static level from the depth of the well and get the value of the borehole water column.

4. Pipe diameter.

These parameters can be measured independently or resort to the help of specialists..

What type of pump to choose?

If the distance to the water surface is not more than 9 meters, then you can purchase a surface pump. A submersible pump is also suitable, but note that the depth of the pond should exceed 1 meter. Otherwise, instead of water, you run the risk of getting sludge, sand and air.

An important source of fluid is. If water is taken from a well for drinking, and from a river for household needs, it is better to choose a surface pump that can be moved, whereas this number will not work with a submersible.

If the depth is more than 8 meters and the water quality leaves much to be desired, then pay attention to centrifugal pumps. When choosing, pay particular attention to performance and pressure. Now when water pumps for the wells considered, and the appropriate type of device is selected, you can proceed with installation.

Installation of a pump in a caisson arranged for an aquifer

How to connect a pump to a well?

The well pump should be mounted 10 meters below the dynamic level indicator. If the equipment is installed to a depth of more than 80 meters, then you need a pipe for 16 atmospheres, if to a depth of 80 – 12.5 atmospheres.

It is important! Be sure to install a check valve on the pump unit..

Connect the pump to the water pipe through the brass fitting. The transition from the pipe should be metal and have a sleeve that prevents the pipe diameter from decreasing due to the voltage of the compression fitting.

Installation of a borehole pump

The second end of the pipe must be connected to the outlet of the head by means of a driven brass fitting. Using a cable sleeve, the pump communicates with the conductive cable. With plastic clamps, we attach the cable in the water pipe every 3 meters.

You need to know! Instead of clamps, it is allowed to use electrical tape.

Attach a stainless steel safety cable with a diameter of 5 mm to the head and pump. Do not use ferrous metal or galvanized steel cables. Done. It remains only to lower the pump into the well.

Now you know how to install a pump in a well, and you can enjoy the usual amenities even away from urban civilization.