The choice of pipes is very large, and many people have a question – which pipes are better for water supply? To determine this diversity, it is necessary to take into account the following parameters – temperature, the nature of the medium, the required durability, pressure in the water supply pipes, as well as your financial capabilities. After reading this article, everyone will be able to choose the most suitable option for him. Conventionally, pipes for water supply are divided into 3 groups: metal-polymer, polymer and metal.

Content

- Metal pipes: pros, cons

- Standard steel pipes

- Stainless steel pipes

- Copper pipes for water supply

Metal pipes: pros, cons

Their common advantages are high strength and “reference oxygen resistance”.

Standard steel pipes

Steel pipes are reliable but not protected against corrosion

The main advantages:

- Availability;

- Relative cheapness;

- High strength.

The main disadvantages:

- Lack of protection against internal and external corrosion;

- High assembly labor.

As a result – overgrowing of the inner diameter, leaks, rusty water, etc. Steel pipes according to SNiP must be changed every 25 years.

Assembly is carried out by gas or electric welding, as well as using standard threaded connectors with a seal (tow, sealant, etc.).

Stainless steel pipes

The main advantages:

- Beauty;

- Reliability.

The main minus:

- High price;

- The high cost of installation.

As a result, such pipes are not in high demand..

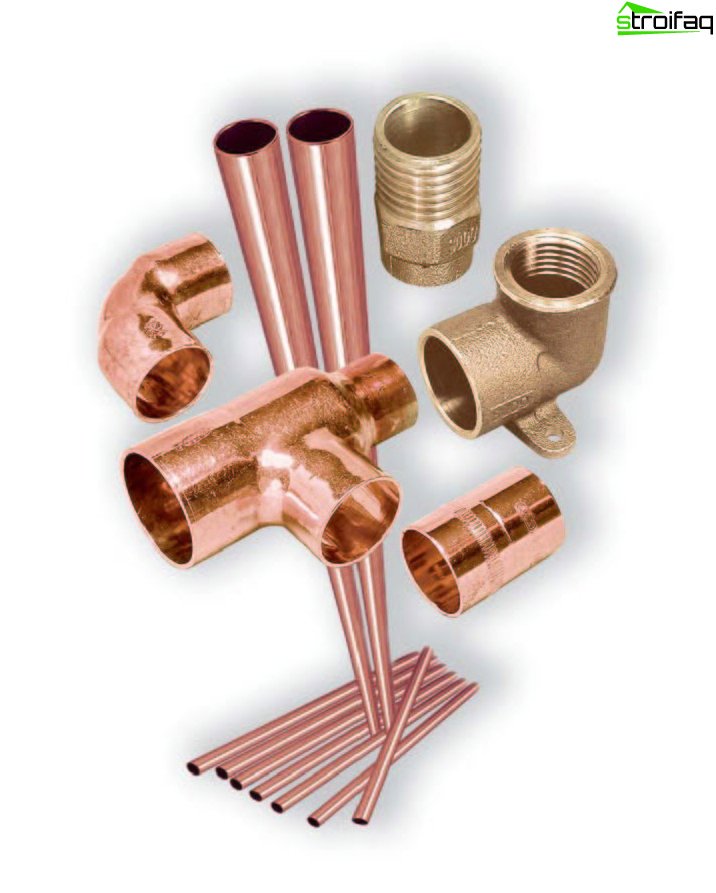

Copper pipes for water supply

Copper pipes and fittings are durable, but not applicable to water systems that supply water with high acidity

The main advantages:

- Beauty;

- Reliability;

- Durability;

- The ability to withstand any temperature of hot water supply;

- Resistance to the corrosive effects of chlorine and ozone;

- High ductility of the material. Pipes are not only malleable to shape changes, but also capable of not becoming brittle at low temperatures;

- Long term (from fifty to one hundred years) trouble-free operation;

- They withstand a single freeze, and with repeated damage the minimum.

The main disadvantages:

- It is not recommended for use in systems with excessively acidic water, with many solid mechanical impurities or with a high flow rate of water;

- Assembly is carried out by high-temperature capillary soldering, threaded connections or press fittings.

The era of polymer piping

Today, there is a steady upward trend in demand for these pipes. This is due to the following undeniable advantages of polymer materials:

- Corrosion resistance;

- Low weight;

- No deposits on the walls;

- Small friction head losses are small;

- Not afraid of the action of stray currents;

- Resistance to many chemical compounds;

- Low thermal conductivity.

Disadvantages:

- Oxygen permeability;

- Intolerance to direct exposure to sunlight;

- Loss of strength depending on load and time;

- Inapplicability in fire water supply systems;

- Special mounting and welding equipment is required;

- Need protection against accidental damage (including rodents).

In the domestic construction market, plastic pipes of 3 generations are offered:

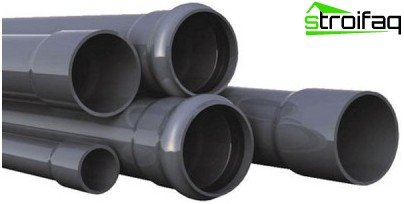

1st generation – PVC pipes (polyvinyl chloride)

PVC pipes are cheap and practical

The main advantages:

- High strength;

- Chemical resistance;

- Abrasion resistance.

The main disadvantages:

- Increased toxicity;

- Flammability.

In European countries, such pipes for cold water are practically not used. They are used there mainly in domestic sewage systems..

2nd generation – polyethylene pipes for water supply

Polyethylene pipes are used mainly for the organization of cold water supply systems.

The industry produces 2 types of polyethylene: high pressure LDPE and low pressure HDPE. HDPE pipes for water supply are an excellent alternative to traditional metal pipes for water supply. This is a high-tech modern solution to the problems of the construction of water supply systems. They are easily connected to pipes of any other materials. The cost of such pipes is small.

The main advantages of polyethylene pipes:

- Resistance to low temperatures up to -20 ° C.

The main disadvantages:

- At high temperatures, the strength of polyethylene decreases, and it becomes plastic-viscous;

- From direct sunlight, the material ages quickly..

As a result, these pipes are not used for hot water supply..

Cross-linked polyethylene pipes

The main advantages:

- Great strength;

- Higher temperature resistance.

The main disadvantages:

- Unsuitable for welding.

As a result, such pipes can be used for hot water supply..

3rd generation – polypropylene pipes

Polypropylene pipes – a combination of the best technical characteristics

- Physical longevity;

- No painting required;

- Lower thermal conductivity;

- Light weight;

- Lack of electrical conductivity;

- Lack of chemical corrosion;

- Easy installation – installation of such pipes is two to four times faster than steel pipes;

- Not susceptible to lime deposits, solvents, acids or other chemicals;

- Chemical resistance. Polypropylene does not affect water quality;

- Acoustic insulation (water leakage and water hammer noise do not cause resonance).

The device of a plastic pipe

Metal-polymer pipes – a symbiosis of virtues

They combine the best qualities of pipes made of plastic and metal, but at the same time they are devoid of most of their shortcomings. Consist of several layers:

- External – cross-linked polyethylene, resistant to ultraviolet rays;

- Middle – aluminum pipe with a wall thickness of 0.2-2 mm, welded along the length of an overlap or butt;

- Inner layer.

Such pipes can be bent, after which they retain their shape. And due to their high strength, such pipes withstand pressure up to twenty MPa and temperatures up to 95 ° C. The diameter range of these products is quite large – from 14 to 110 mm.

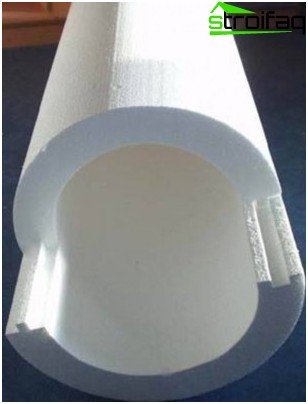

Expanded polystyrene is the most demanded material for thermal insulation of water pipes

How to insulate the water supply?

Fiberglass heaters are used for insulation of metal-plastic pipes. When insulating glass wool, an additional external insulator is required – rolled material, for example, fiberglass or ruberoid.

Expanded polystyrene (polystyrene) is the most common material for household insulation of water pipes. Expanded polystyrene insulation shell is used both with an external coating and without it; stacking of trays is optional. The use of polystyrene is designed for repeated use.

Basalt heaters are cylinders made of insulating material. The obvious advantage is the ease of installation of the cylinders. The disadvantage is that their cost is by no means the lowest. The protective coating layers are made of foil isol, roofing material or glazed.

All modern heat-insulating materials for insulation of water pipes have a general principle of action – air, which is located in the space of the insulation, acts as a heat insulator. Therefore, the choice of thermal insulation depends only on the location of the pipes and ease of installation.