Caissons for wells

Artesian wells help resolve issues related to the water supply of country houses, such as: getting drinking water, irrigating agricultural plants, using water for other needs. The climate features of our region make the owners of private households think about placing all the water-lifting equipment below the level of freezing of the soil. Otherwise, the system may freeze. In turn, this arrangement of communications leads to the ingress of groundwater into them, which significantly affects the purity of drinking water. Probably, no one wants to open the tap to find in it the products of the neighbors. Well caissons for wells help prevent these troubles..

Content

- Functional responsibilities, geometric differences

- Types of caissons, their disadvantages and advantages

- Self-assembly of a caisson for a well

Functional responsibilities, geometric differences

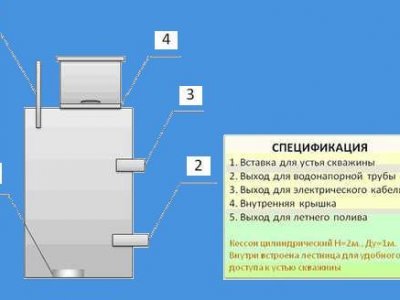

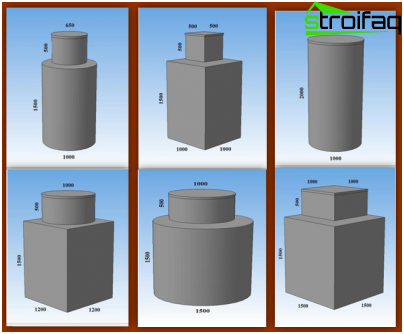

In appearance, the caisson is an ordinary box or barrel with a neck, which is closed by a manhole cover, usually insulated with foam. Cylindrical caissons, whose diameter in the main part is one meter and a height of at least two meters, are widely used. If the diameter of the device is less than a meter, then it is not possible to carry out maintenance in it, and caissons with a large diameter are expensive due to the consumption of more material.

Caissons of various shapes

Caissons – waterproof equipment, waterproofed on the outside and primed on the inside. For better thermal insulation, the inner surface of the device is covered with foam. This simple device allows not only to reliably protect the system from freezing and ingress of groundwater, but also to become a small underground room, allowing necessary repairs to be carried out in any weather.

In addition, the caisson allows you to place inside yourself such necessary equipment for the correct operation of the system as a pressure switch, a pump control panel, a membrane accumulator and other automatic devices, reliably protecting them from unauthorized access.

Types of caissons, their disadvantages and advantages

At the moment there are three types of caissons for wells:

- metal;

- reinforced concrete;

- plastic.

Let us consider in more detail each type, what are their disadvantages and advantages.

Metal caissons are the older generation of such devices. Usually stainless steel or aluminum is used for their manufacture, since they are most resistant to corrosion. In addition, the metal belongs to flexible materials, which prevents the occurrence of cracks. A high-quality metal caisson is made of steel, the thickness of which should be at least three millimeters.

Such equipment requires mandatory anti-corrosion treatment on the outside and priming inside. But it will serve for several decades. You can install a metal caisson for the well with your own hands, while significantly saving on installation work.

Caisson made of reinforced concrete rings: durable, almost eternal, but quite expensive, in addition to requiring insulation

Reinforced concrete caissons are made from reinforced concrete rings. Installation of such a device requires considerable effort and financial costs. These designs are considered the most expensive. Concrete rings are placed on a specially prepared base. Since concrete is a very hygroscopic material, caissons made from it require enhanced waterproofing from the outside. In practice, it is very rarely possible to achieve absolute moisture impermeability of the structure and groundwater still gets inside.

Another significant drawback of reinforced concrete rings is poor thermal insulation. Very often, in severe frosts, equipment enclosed in caissons of this kind freezes anyway. And the heavy weight of the material leads to a gradual subsidence of the device as a whole, leading to deformation of the equipment used.

The economical plastic caisson is not “afraid” of rust and corrosion; it has served excellently for many decades

A plastic caisson for a well is made of polymer materials, its wall thickness is about 20 mm. Such devices are very durable and have a long service life. They are completely non-corrosive and waterproof. By installing a plastic caisson, you can save on waterproofing and anti-corrosion compounds. Structures made of plastic or fiberglass are not recommended for well protection, since under the pressure of groundwater they can deform strongly and also “float” to the surface due to light weight.

Self-assembly of a caisson for a well

Installing a caisson on a well in-house does not require any specialized skills. Such work is within the power of any person who has the slightest idea about this process. So, how to make a caisson for a well yourself?

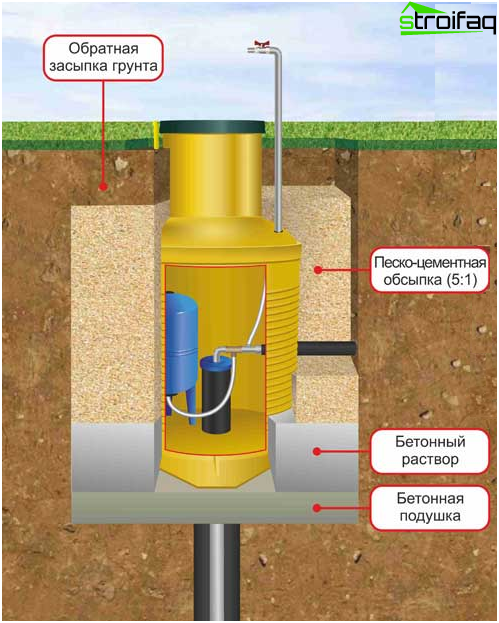

Around the finished well, it is necessary to dig a pit with a depth of at least two meters and with dimensions exceeding the dimensions of the caisson by at least 10 cm in each direction.

The pit is dug with the fact that the neck of the structure should be above the surface at a distance of at least 10 cm. This will prevent rain and other surface water from entering the caisson.

How to fix the caisson in the ground

Now we proceed directly to the installation of the caisson. On the bottom of the device, mark the location for the hole required for the casing. The hole can be shifted in any direction, based on personal requirements..

Tip: If you plan to place the accumulator in the caisson, the hole for the casing will need to be slightly shifted from the center. This is necessary so that after installing the pressure tank it was possible to lower the tool into the hatch.

Important: cable and hydraulic leads must go to the place of entry of the pipeline into the house.

The main thing is that as a result, the casing gets into the hatch. A sleeve of a larger diameter is welded into the cut hole than the pipe itself, and 10-15 cm long.

Tip: Before welding the sleeve, be sure to put it on the pipe to make sure that it can be done with a small margin.

In this case, the casing pipe must be cut at a height of about 300-500 mm from the bottom of the caisson and made into a cone using longitudinal cuts at the end and a sledge hammer.

The caisson should be prepared in advance: bochata should be welded into its walls, necessary for the output of pipes into the trench. One pipe will be needed to enter the cable, and the rest to output the water system.

Next, the caisson is installed above the pit so that the axis of the liner and casing coincide. First, the structure is installed on the bars, after pulling out of which it will lower into the pit along the casing, which acts as a guide. Now the caisson is set horizontally in level, for which it is necessary to set the bars between it and the walls of the pit.

The sleeve should be welded around the perimeter to the casing and after that, the HDPE pipes should be inserted inside the caisson through pre-installed nipples. All welds are treated with a primer..

Important: for PND 40 pipes, a nipple of 1.5 inches is required, and for PND 32 – 1.25 inches. If the pipes are difficult to pass, then the inner surface of the nipple is treated with a coarse file.

Sealing pipes inside the nipple is carried out by PND-junction with internal thread. An electric cable is pulled through one of the pipes to power the pump. As a result, we get an absolutely hermetic structure that reliably protects the mouth of a water well.

For best results, you can mount the second cover in a foam and plywood caisson at a distance of 30-50 cm from the first, and insulate the upper part of the structure. Do not forget that the slightest violation of the installation rules can lead to failure of the entire water intake system, so it’s better to invite a specialist who can draw up an adequate algorithm of actions and organize its clear execution.