Well pumps

Organization of water supply for a summer house or a country house is one of the main tasks of the owner. In the absence of a centralized water supply, wells or wells solve the problem of water production. Mine wells are being built with the aim of collecting non-pressure groundwater, which lie at a depth of not more than 10 m. This does not mean that wells cannot be built deeper, it is simply not economically viable. In this case, a well is drilled. Moreover, in both cases, the choice of equipment providing water supply is necessary. Its role is played by various pumps for wells, which manufacturers produce various capacities in terms of pressure and volume of injected water per minute.

Content

- Choice is a solution to a fundamental issue

- Temporary use of a well

- How to choose a pump for a well

- Determining sufficient performance

- An important parameter is pressure

- Unit Type Selection

Choice is a solution to a fundamental issue

Many do not know how to choose a pump for a well from a wide range of equipment offered on the market by foreign and domestic manufacturers. To make a competent choice, experts advise answering a number of questions, namely:

- What is water for (watering the garden, washing the car, supplying the house and other purposes)?

- What are the parameters of the well (the level of groundwater, the depth of the water in the constructed well, the distance to the house from the well, its estimated productivity)?

- What is the minimum required pump capacity?

- What is the design head that the pump should provide?

- How long will pumping equipment be used throughout the year?

Temporary use of a well

For the organization of well water for temporary use for technical purposes (watering summer cottages, construction work, washing the car), you can purchase a submersible pump for a well of vibration type. It can be “Kid”, “Summer resident” and other equipment with similar technical characteristics. It should be borne in mind that submersible vibration pumps do not have stringent requirements for performance and pressure. Seasonal use simplifies the operation of this pump. If it is necessary to provide year-round full-fledged water supply to the cottage, then pay attention to more serious and powerful pumping equipment.

How to choose a pump for a well

Determining sufficient performance

To determine the required pump capacity, all “water points” available in the house are taken, which include taps in the bathroom and kitchen, shower, toilet, washing machine, as well as an irrigation system located outside the house. Summing up the water consumption of all devices turned on at once gives the required pump performance. It is already known that for a comfortable life, water taps should “give out” about 0.6 cubic meters of water per hour.

At the same time, the performance of pumps that can provide water to a small cottage should average 2-4 cubic meters per hour. If you buy a pump below the rated capacity, then during peak hours it will not provide the necessary amount of water, which will affect the work of the equipment installed in the house.

An important parameter is pressure

The pump head, in the passport indicated by the manufacturer in meters, should provide:

- sufficient water pressure in the water supply system for household appliances;

- rise of water to the maximum height at which there is a water point in the house;

- overcoming the resistance arising in the pipeline during the movement of water.

Unit Type Selection

In addition to taking into account the above parameters, when choosing pay attention to the type of pump. Well pumps can be surface and submersible. At the same time, each type with individual advantages has its own field of application. How to understand which pump is best for a well to choose from these two types? We must deal with the features of their action.

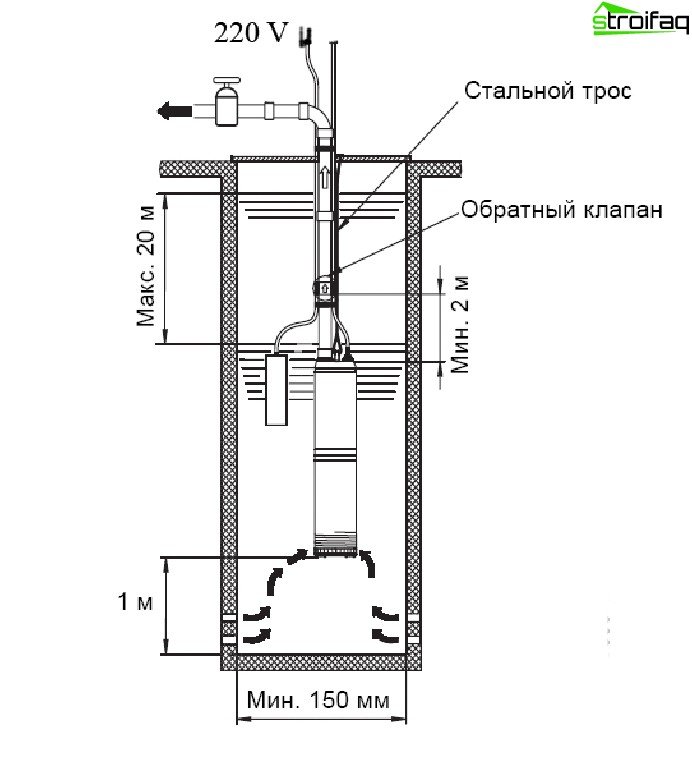

Well pump installation diagram

Self-priming Surface Technology

These devices are widely distributed among the population. One of the reasons for their popularity is the peculiarity of their location – outside the source of water. In other words, installation of the pump in the well is not required, which facilitates its maintenance and repair. Indeed, sometimes surface pumps are installed directly in the building. This equipment is capable of lifting water at a depth of 7-9 meters. Moreover, the cost of such pumps is one third, and sometimes half, less than the cost of submersible equipment with equal performance indicators. Produced by the companies CALPEDA, SPERONI, NOCCHI, SIX-TEAM (Italy), WILO (Germany), GRUNDFOS (Denmark), GILEX (Russia), EBARA (Italy-Japan).

The main disadvantage of surface self-priming pumps is the limited suction height. To increase this parameter, you have to place the pump closer to the well or increase the diameter of the pipes. Many people simply prefer to buy an immersion device that is not aware of these problems..

Submersible Well Equipment

Well submersible pump

These devices, based on the name, are designed to work under water. Moreover, their design provides for the cooling of a running engine with pumped water. Therefore, when turned on without water, the equipment may overheat, which will cause it to break. When installing the pump in a well, one must remember the dangers of working “on dry run”, and arrange the equipment so that it is always under water, regardless of fluctuations in its level. To ensure safety, automation is used to turn off the pump during a catastrophic decrease in water level. Accordingly, after filling the well with water, the pump automatically turns on.

Submersible well pumps are most often chosen for organizing water supply in country cottages. They are characterized by reliability, simplicity of design, low price when compared with the cost of other submersible models. Submersible well pumps are capable of lifting water from depths of up to 70, and sometimes even 100 m. They are produced by manufacturers WILO (TW5 / TW5-SE series), LOWARA (Scuba series), EBARA (Idrogo series), NOCCHI (Pratika series), CALPEDA (MXS series), OFT (Italy, Trend series), GILEX (Vodomet series), KERSELF (Italy, Omega 12 series) and other manufacturers. These devices are appreciated for the ability to supply water to fairly high altitudes..

Mounting the pump in the well

Submersible pumps are suspended on a cable, which is pulled through the eyes located in the top cover of the well structure. In this case, you must choose a cable very carefully. The use of a conventional metal cable is not considered advisable, since the material will corrode and collapse after four years. Therefore, experts recommend choosing cables that have a protective coating. Also, to prevent corrosion, polymer pipes should be used, with which they connect the pump to the discharge pipe.

Pump installation

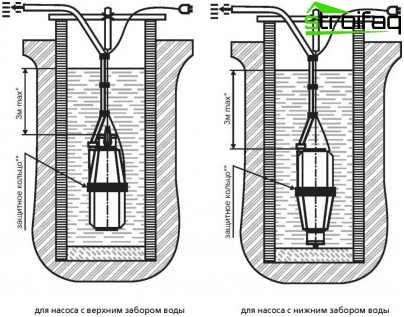

Install a household deep well pump for the well so that water is drawn at least a meter from the bottom of the well. Otherwise, the pump will tighten sand and other dirt along with water, which may damage it. Manufacturers will improve pump models, preventing them from sucking in contaminated bottom water.

Some models provide water intake through a pipe connected by a flexible hose with a floating filter. Thanks to the float, the filter is always located below the water mirror, which makes it impossible for suspended particles to enter the pump. Such designs are best for wells with a sandy aquifer.

Well pump installation diagrams

Experts recommend purchasing a centrifugal pump for a well, since such a device is unpretentious and able to work in wells in which water does not shine with special quality. Suitable for intensive use over a long life.

In wells, horizontal installation of pumping equipment is usually practiced. For horizontal installation, a protective cover is recommended. This will protect the motor from deposits of dirt and sand. It will also provide the desired flow rate that runs along the motor.

What pumps are made of?

When choosing a pump, it is necessary to take into account the material that manufacturers use to make the casing and the impeller. More expensive and durable products are made of stainless steel. In budget models, a plastic case is very often used. An electric cable always comes with the pump, the length of which can reach 20 meters, as well as a check valve. If there is no float switch in the pump kit, it is recommended to buy it separately.

Additional devices and accessories

- A storage tank is necessary to maintain constant pressure in the water supply system. Its installation protects the pump from possible frequent starts, and also protects the water supply from hydraulic shocks. At the time of a power outage, capacious tanks act as an emergency source of water. A hydraulic accumulator is a container made of fiberglass or metal, partially filled with water, and partially with air under pressure of 0.2-0.5 atm. It is advisable to have a larger tank, but this affects the cost.

- Pressure switch, providing automation of the pump. It turns on the device when the pressure in the accumulator falls below the minimum limit. Then it turns off the pump when the upper maximum limit is reached. In the absence of automation, the pump must be monitored visually.

- The power cable must have a double insulating layer. It is also necessary to protect it from possible damage, for example, by animals or a lawn mower..

Useful tips for installation and operation

- The well must be kept clean. Therefore, periodically it should be drained completely, cleaning the bottom and walls.

- Clean water filters regularly. In this case, the pump must be removed and the filter element removed from it. After washing it under a stream of running water set in place. This procedure will extend the life of the equipment and also maintain the proper cleanliness of the fluid pumped by the pump..

- Install a check valve in the outflow hose. This will reduce the negative impact of water hammer..

- The pump should be used strictly for its intended purpose. Thus, a device designed to work with clean water is not lowered into a silty, untreated well. Otherwise, it will not be possible to avoid an early breakdown of the unit..

We hope that after reading this article, questions about choosing a pump for a well disappeared by themselves. If you need additional advice, contact sales consultants. Take your time to buy equipment until you find out all the details of its use in your well.