Do-it-yourself pumping station for home and garden

Pumping stations for summer cottages and houses help to solve one of the most important problems arising for owners of private housing in the city and outside it – water supply. Of course, the issue of banal watering can be “exhausted” by not so global methods, but if it is a matter of well-established water supply, a pumping station for the house is an optimally obvious option.

Its installation and commissioning, armed with relevant knowledge and practical recommendations, can be done independently. Moreover, not every region boasts the presence of a specialized service that carries out the installation of a pumping station.

Content

- Advantages of the pump unit

- Device and principle of operation

- Technically competent installation of SAV

- Pumping Stations – Reviews

Advantages of the pump unit

An automatic pumping station is able to maintain the pressure that is necessary for a full stable supply of housing or land with the most important liquid, at a level not worse than in a classic city water supply.

Domestic CAB is able to function for some time without power supply. She has a fairly light weight. Even one person can carry out the installation process – and the connection itself will take a few minutes. It, unlike the storage systems mounted, as a rule, in the attic, can be placed in any place you think is appropriate. Which is also a pretty significant advantage, isn’t it?

Equipment wear is minimal, because the pump does not work continuously: it is switched on periodically (as necessary). In a word, a pumping station, without false exaggeration, is able to properly serve you for many years. The main thing is to approach the installation process at all stages responsibly and carefully. Finally get rid of the rumble of buckets and fuss with washbasins!

Device and principle of operation

Let’s try to figure out what this equipment consists of. Mostly the main “figures” in such installations are one or more ejector-type pumps (working, standby), or, to use an understandable language, self-priming. They capture and lift water from a ten-meter depth.

In addition to these, the system also includes a steel pressure tank – a closed container divided into two cavities by a membrane, one of which is for water and the other is filled with high pressure air.

Accumulator volumes can vary from 20 to 80 liters.

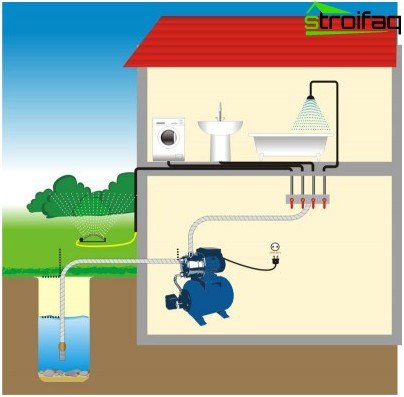

CAB installation diagram

Your site has been turned off, but do you need water? Do not despair – the water supply pumping station is capable of functioning for some time without “feeding”. How is this done? Elementary. The fluid pumped into the tank, due to air pressure in the corresponding cavity, is transported into the pipeline. It simply cannot flow back into the pump – the non-return valve acts as a powerful barrier. As you can already understand, electricity is not required at all. That is why the membrane tank is called the accumulator.

Typical design of the pumping station, the principle of the sewer system

The device of the pumping station implies the presence of an automation unit with pressure sensors, a fuse for dry running (idling), protection against engine overheating.

The principle of operation of the pumping station is as follows:

- water entering the membrane tank;

- when the pressure in the tank reaches a certain value, the pump turns off (a special relay controls the process);

- the system goes into “waiting”;

- when the tap is opened, water supply from the tank begins;

- after the “expiration” of a certain amount of liquid, the pressure in the tank drops to a predetermined value;

- the pump starts up again.

Due to the pumped liquid, the station is cooled. If the engine is still overheated, the automation will shut off the pump.

Technically competent installation of SAV

In order for the pumping station to function for a long time without failures, it is necessary to carry out its competent installation: provide a smooth, solid surface; provide hard mount.

The base for the pumping station is better to make concrete. If this is impossible, in principle, you can do with a wooden shield – in the role of the base, it is also pretty good.

To create a wooden base you will need such materials:

- two bars with a section of 100×150; their length should be with a margin of 300 mm on each side (relative to the width of the station);

- two edged boards 50 mm thick / 150 mm wide; the length of these should provide a total protrusion along the length of the station of about 80 mm;

- sand and clay.

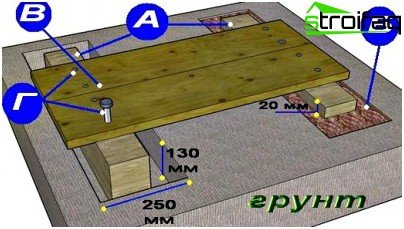

The surface of the favorite place for the installation of CAB must be leveled. Then dig out two rectangular grooves, 130 mm deep / 250 mm wide, on the bottom of which it is necessary to lay the bars (A) treated with an antiseptic (preferably tar) and check the level of their horizontal placement.

Important! The exact distance between the grooves depends on the location of the mounting holes for your pump station.

Around the bars is a sand-clay mixture (B): the ratio of clay and sand is 1: 3. It should be thick enough, succumb to ramming. The bars should protrude above the ground by 20 mm or more. Then, edged boards (B) are attached to the bars with nails with countersunk heads. Boards, of course, must also undergo antiseptic treatment.

Scheme of the device base for the pumping station

After a couple of hours, when the structure is firmly fixed in the hardened mixture, you can proceed to the direct installation of the pumping station. САВ is installed on the boards and fastened with special screws.

Between the base and attachment points, be sure to install gaskets about 10 mm thick. It is not recommended to use thicker samples – this is fraught with a decrease in the rigidity of fastening and a negative impact on the overall performance of the system.

Remember! The complex should be located as close as possible to the well, borehole or any other source from which water will be drawn..

How to connect a pumping station?

Do-it-yourself pumping station is simple, convenient and profitable. Elements required for its connection:

- check valve;

- suction hose;

- CAB directly;

- dry run protection.

For proper operation of the station, a hose of at least 1? (for suction) and a check valve at its end.

In stores you can find the “Suction kit”, consisting of a fitting, a hose and a check valve.

Pump station connection diagram

So, the kit is attached to the pump, and the other end of the hose is lowered into the water. Then water is poured into the pump. The pipe is connected to the pressure system of the house. Performing these simple manipulations, you will provide yourself with maximum user comfort. If the station is used 365 days a year, a large amount of preparatory work is necessary. SAW should be kept warm; the pipe connecting the house and the well must be insulated without fail or located in the ground below the freezing level. Well also would not hurt to warm.

Important! Do not neglect to read the “Operation Manual” – this will help prevent a lot of mistakes..

Pumping Stations – Reviews

When you first encounter a device, especially if it is supposed to be used for a long time within the “framework” of your own housing or land, there is a very natural desire to learn about other people’s impressions of contact with the mechanism. Pumping stations for giving reviews receive only the best. But this in no way prevents user views from being extremely objective. Based on their own experience, the owners of the CAB recommend:

- if the station is installed in the basement near the foundation, it is necessary to isolate the SAW with mineral wool insulation in order to prevent freezing of water;

- do not install the CAB in hard-to-reach places, cover it with a tarp, etc. This will adversely affect the life of the device;

- frequent tripping of a thermal relay is a serious reason for communicating with a specialist. Its forced inclusion provokes breakdown of the entire engine.

Do not be greedy when purchasing this installation. A quality pump plus a competent installation equals long years of service of the mechanism. But it is not worth the overpay for fixtures of dubious necessity. This is another case where the golden mean is it.