Well and well pumping station

Providing water supply to a country house is one of the main and main tasks that must be solved in the first place. Own well or well on the site will allow you to be completely independent of imported water or neighbors. An additionally installed pump station for a well or a pump station for a well will bring comfort and coziness to a private house. Installation of pumping stations is the most optimal solution to the issue of constant pressurized water supply and will allow you to enjoy such benefits of civilization as a shower, automatic washing machine and much more.

Content

- Options for organizing water supply

- The principle of operation of pumping stations

- Water intake calculations for a pumping station

- Connecting the unit to the well

- Connecting a pumping station to a well

Options for organizing water supply

There are several options for creating a water supply at home. It all depends on the method of obtaining water, it will be water from a well or from a well, from depth and productivity, as well as from the level of water in a well or well. To choose the right pumping station, you should know the features of their installation, equipment and operating conditions, as well as have a pre-prepared project for water supply at home.

Pumping stations of any type have a similar design and differ among themselves by the method of water intake, carried out through a well or a well, and operating characteristics. A fully installed and working pumping station includes a pump, a hydraulic accumulator (a large-volume tank of about 80 liters), a control relay, and a connecting hose. Such a standard pumping station assembled at the factory can be found in almost any store that specializes in goods for country houses and cottages..

The principle of operation of pumping stations

Modern pumping stations operate as follows. After start-up, the pump pumps water into the accumulator and creates pressure in the entire water supply system, which is laid in the house. As soon as someone starts using the faucet in the bathroom, shower or just washing dishes in the kitchen, the pressure in the system gradually drops to 2.2 bar, and a pressure switch that activates the pump is activated. He, in turn, again pumps water into the tank, compensating for its loss, and raises the pressure to 3 bar, after which the relay reacts again, and the pump turns off. Everything is extremely simple and concise, the main condition for the smooth operation of the pumping station is the availability of electricity and a sufficient amount of water in the intake.

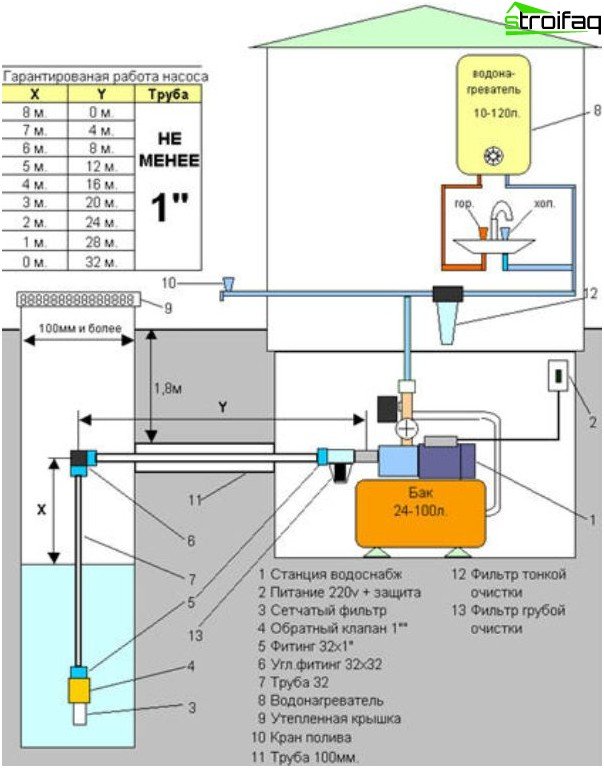

Pump station design, operating table

Pumping stations are often equipped self-priming centrifugal pumps with integrated ejector. This type of pump has a high head of water supply from 40 m and a suction depth of up to 9 m. One of the main advantages of this type of pump is its low sensitivity to air in the system. Starting such pumps is not difficult. It is just necessary to open the filler cap, fill the pump with water until water flows over the edge, then close the cap and turn on the pump. After the pump pumps air, it will begin to supply water to the system. To get rid of excess air, you can simply open the tap or valve on the pump itself. A pumping station for wells equipped with such a pump will be most effective in operation.

Also exist self-priming centrifugal pumps with external ejector. Such pumps are installed in pumping stations for deep wells and wells. A pumping station for wells and wells equipped with this type of pumps will be able to pump water from a depth of up to 45 meters. Such stations are installed on the surface or in specially designated premises, and an ejector attached to two pipes is lowered into a well or well. One of the pipes is designed to supply water to the ejector and create suction, and the second – to raise water. The disadvantage of this type of stations is the high sensitivity of the pump to the air in the system and pollution. The advantage is that such stations can be placed in the house, and the ejector can be lowered into the well or well, which is located at a distance of 20-40 meters from the house.

Pumping stations for wells or boreholes have a characteristic such as suction lift. Some stations can lift water from a depth of 8 meters, while others from a depth of 20 to 45 meters. If the characteristics of the pump indicate a suction depth of 8 m, this does not mean that it cannot be used in a well with a depth of 15 m. The required depth is determined by the level of the water mirror or, more simply, the level from which this water can be pumped. The thing is that the aquifer can be at great depths, and the groundwater level at a depth of 2-6 meters or more. And here knowledge of physics, namely the rules of communicating vessels, comes in handy. Water from a depth under pressure rises in the well or well to the level at which the groundwater is located, and reaches a level of 2 to 6 meters.

In areas where the groundwater level is very deep, and in the well water at a level of 10 m or more, submersible pumps are used. Such pumps are lowered into the well to the water level, pump it up and raise it up. In the case of a well, the pump is also equipped at a depth sufficient for injection. The suction height of the pumps is most often 8 m, and they can push water to a rather high height. For example, in a well 90 m deep, the pump is installed at a depth of 60 m.

Important! When buying a pumping station of any type, you should pay attention to its configuration. First of all, this is a check valve. Its presence will protect the pumping station from idle and extend its service life. The next important element is the input filter. Its presence will keep the check valve and pump from the ingress of sand and dirt. All other elements, such as a pump, an automation panel, a hydraulic accumulator and a water connection hose are included.

Water intake calculations for a pumping station

To install a pumping station of any type, you should first find out the productivity of the well or well, the level of the water mirror, the possible volume of water consumed and the pressure in the system. So that a well or a well can provide uninterrupted supply of water to the house, the productivity of the pumping station should not exceed the productivity of the well or well and at the same time be greater than the possible water flow.

By summing up the data of the installed elements, you can get the flow of water while turning on all consumers.

Having received the necessary data, you can proceed to the selection of a pumping station with suitable parameters, which are indicated in its passport.

Important! Data on the productivity of a well or a well can be obtained empirically. Install a motor pump or a conventional surface pump and measure the volume of produced water. You can find out the level of the mirror by lowering the nut tied to a strong thread, and then taking measurements. If there is a passport for a well or a well, then this data can be found there.

For year-round use of the pumping station, it is best to place it inside a specially designated utility room.

Inside the room, pipes are routed to all points of water intake. Filters for coarse and fine water purification, a manometer and an automatic control panel are immediately installed.

Connecting the unit to the well

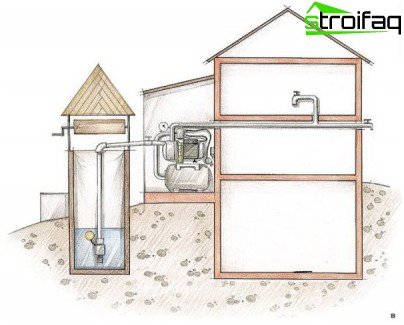

Water supply of a house based on a well takes place according to the following scheme. A utility room is located in the house or nearby, in which the pump station is located. For work in the winter, the room temperature should not fall below 2 ° C. As previously stated, for wells it is better to use pumps with a remote ejector, since the well is usually located at a distance from the house.

Well pumping station

To protect the pipes from freezing in winter, it is better to lay them in a trench to a depth of 1.8 meters. We install a mesh inlet filter on the suction pipe and lower it below the level of the mirror. At the inlet in front of the pump, we install a coarse filter and a check valve. After the pumping station, we put a fine filter and then we connect the manometer, pressure switch and the rest of the plumbing. Directly connect the station to the control panel.

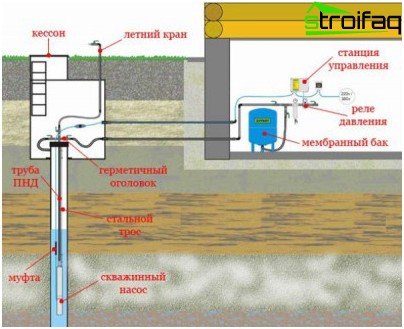

Connecting a pumping station to a well

Pump station, well connection diagram

After the well has been drilled, the casing remains on the surface. Further, the connection of the pumping station to the well can go in two ways. The first is the construction of a utility room above the well. The second is the installation of a caisson. In the first case, it will be somewhat inconvenient to heat the room if it is located at a great distance from the house. And since we have severe winters, the heat loss will be large.

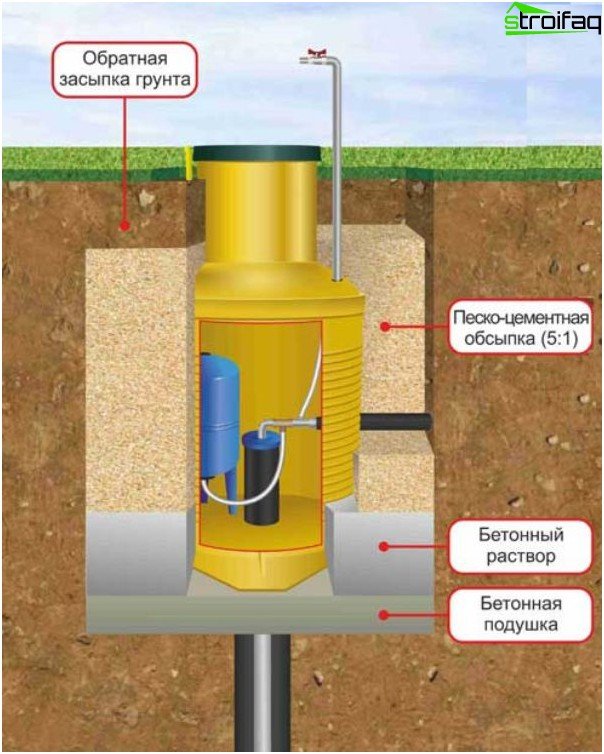

Therefore, the best solution is equipment. caisson.

The best option for servicing and operating a pumping station – installation in a caisson

To do this, the casing is dug to the depth of the caisson installation, usually about 2.5 m. A concrete cushion is poured, and a caisson is installed on it. The casing is cut so that about 500 mm remains inside the caisson. From the caisson to the house, we dig a trench 1.8 – 2 meters deep and put underwater pipes into it. The pump station can be installed in the caisson or in the house, it depends on the type of station itself. Installing a pumping station in a well makes sense when the pump is remote. Then in the utility room of the house there is only a hydraulic accumulator, filters and a station control panel.

Modern comfort implies the presence of a washing machine, shower, bath, toilet in the house, boiler and many other benefits of civilization. Previously, their installation was either impossible or difficult. Today, the presence of various types of pumping stations and pumps allows you to provide previously inaccessible comfort in a country house.