Drainage well

The drainage well is used in a system of deep (or ground, closed) drainage, designed to lower the groundwater level by diverting them from the site. Such a system is necessary to protect the soil from waterlogging and waterlogging. On the site, one to several wells connected by drains can be equipped. Their number is determined by the area of the site, soil composition and other factors. The purpose of the well may vary depending on its type.

Content

- Types of drainage facilities

- Materials for the device

- How to make a drainage well?

Types of drainage facilities

This engineering structure is a buried tank consisting of a shaft, a bottom (absorber is absent) and a hatch into which groundwater flows from drainage drains (pipes). There may be several types.

Placement of different types of drainage wells on the site

1. Revision (inspection or inspection) – Designed to clean drain pipes, does not include water collection. Most often, the so-called rotary inspection wells are used, installed either on every second bend (turn) of the pipe, or at the intersection of several drains. In these areas, blockages, siltation, cleaned by a stream of water often occur. Wells can be small (315-425 mm), used exclusively for washing, and large (600 – 2000 mm), allowing a person to go down inside and carry out preventive work. They are installed at the beginning of the drainage system, at the top of the site.

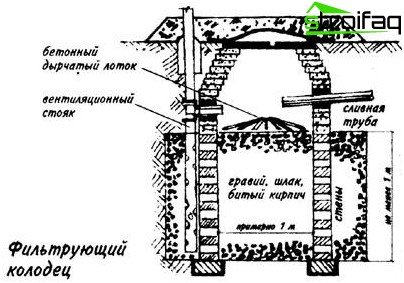

Filter drainage well

2. Filtering (absorbing) – it is built on or off the site when it is impossible to remove moisture to another place of the catchment, for example, to the main sewer, and it is discharged into the underlying soil. It is usually installed with a small volume of groundwater (2 m. Inside the well, a so-called bottom filter made of gravel, crushed stone, boiler slag, broken brick or other similar material is placed 20-30 cm high. The unit is covered with geotextile and covered with soil. Base and external walls are protected by dusting of the same materials.

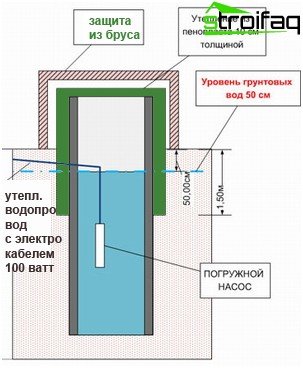

3. Accumulative (water intake) – used when it is impossible to build filter well (for example, with the wrong type of soil and a high level of groundwater), and there is no place for a spillway nearby. Equipped at the lowest point of the site. It is a pipe with a lid and a bottom, protected by sprinkling and geotextiles. The design includes a hose, fasteners for the pump and a pump with which water is pumped out. To connect the pump to electricity, a rubberized outlet is output. The water pumped out by the pump can be directed to a remote ditch, pond or used for watering plants.

Accumulative drainage well: device, principle of operation

Materials for the device

As well as drainage pipes – wells can vary in size and materials of manufacture. As a rule, they are made of concrete or plastic..

1. A concrete drainage well consists of concrete rings of different diameters and heights. Their installation is carried out in advance dug a trench with a crane. The main advantage of a reinforced concrete well is durability and strength, and the disadvantage is the complexity of installation.

2. Plastic drainage wells gradually displace concrete analogues. They are cheaper in cost, they are much easier and faster to mount, they are small in weight, have all the necessary bends, are not subject to corrosion, the service life is more than 50 years, the pipes are connected through rubber lip seals, which can remain airtight for decades. The corrugated pipe of the drainage well is the main feature of these plastic products. Stiffeners hold it in the ground, so it is firmly fixed in the ground.

How to make a drainage well?

Ready-made wells made in the profile domestic or foreign production are reliable, easy to install, have the right diameter, but their main disadvantage is the price. Especially expensive wells – more than 800, 1000 mm in diameter. In order to save money, you can try to make it yourself.

To do this, you should purchase corrugated pipes of the desired diameter. So, for viewing devices, diameters of 340 mm or 460 mm are sufficient so that a person can bend down, let his hand pass and clean the system with water from a hose under pressure. Pipes for filtering and storage wells are better to buy 575 mm, 695 mm in diameter. Or 925 mm, if a person needs to get inside a well.

In addition to corrugated plastic pipes, you will also need a plastic bottom, a cover (hatch), rubber seals of the desired diameter. All components can be ordered separately, which will be cheaper. The sequence of assembly and installation of the storage well may be as follows:

1. Cut the corrugated pipe to the desired length, cut holes in it for drains (at least 50 cm above the bottom), then install rubber cuffs.

2. Mount the bottom, coated with bitumen mastic joints.

3. Prepare a drainage ditch, tamp in it a base of crushed stone, sand and earth.

4. Pour the bottom of the ditch with cement mortar, lay the geotextile

5. Install a well at the bottom of the ditch.

6. Dock pipes with rubber cuffs (coat joints with bituminous mastic).

7. Run the pump.

8. Outside, fill the well with rubble.

9. Install cover.

Important! The soil of the trench should not contain sharp stones and large rubble!

These are the main stages. If everything is done correctly, then any of the types of drainage wells will serve you for several decades, will become an indispensable element of the soil drainage system of the site.