A chainsaw is an indispensable assistant in the suburban area, regardless of its size and the age of the garden. But it is not enough just to become the owner of a good tool, it is still necessary to ensure its correct operation. The most difficult moment is the sharpening of chains for chainsaws. It requires the study of their device and the ability to properly use auxiliary tools.

Content

- Negative worn chain performance

- Tooth structure

- How to determine the need for sharpening

- Sharpen the chain yourself

- How to increase the interval between sharpening

- Choose a sharpening machine

Negative worn chain performance

Determining when to start the procedure is quite simple. With a well-sharpened tool, you do not need to exert much effort to enter the tree. As soon as you need to increase the pressure, you need to sharpen the saw chain. Excessive deterioration affects other important indicators:

- reduced performance;

- increased tension in the body;

- fuel consumption increases;

- increased load on all links, reducing equipment life.

This is useful!

With timely sharpening, less metal is removed, which means that the service life of the chain increases.

Chainsaw will be the best assistant in the countryside

Tooth structure

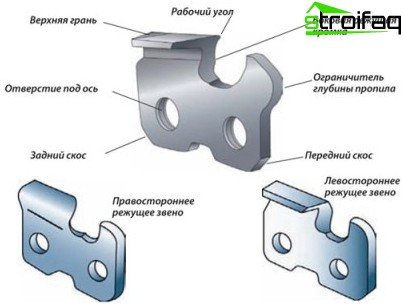

A well-sharpened saw ensures safe and productive work. This is practically no different from other cutting tools. But many teeth and the complexity of their structure make sharpening a painstaking process. If you have the necessary tool, you can do the work yourself. But before sharpening the chain of the chainsaw, it is necessary to study the structure of the tool, especially the teeth.

- The tooth has two edges: upper and lateral. The first is beveled at an angle in the direction of movement of the blade.

- The cutting link consists of a base, tooth scapula, depth gauge. The blade, in turn, has a horizontal, falling back at an angle, blade and vertical end.

- The difference between the upper line of the depth gauge and the front line of the tooth back determines the thickness of the chips. Usually it is 0.5-0.8 mm (ideally 0.6 mm). With each sharpening, this distance is reduced due to a decrease in the upper face of the tooth. Therefore, it is necessary to make a control file after 6-8 sharpening.

- It is the angles that provide the cutting properties of the chain.

The trailing edge of the top edge is the most important. Its value can be from 50 to 60 °.

The rear corner of the end blade is formed by the tapering tooth blade. It plays a role in side cutting chips.

The rake angle is formed by the edge of the end blade with the sliding surface of the cutting link. Depending on the type of chain, its value is 60-85 °.

The tooth of the chain has a complex structure, but after studying it will be easy to sharpen

The sharpening angle is determined by measuring at right angles from the upper cutting edge to the guide rail.

Important! The chainsaw sharpening angles can be different, but you need to remember the basic rule. When sawing a tree of soft breed (unfrozen), productivity is higher, the larger the angle. And it is possible to smooth out the vibration when cutting solid wood (or frozen) by reducing the sharpening angle. In this case, the lowest indicator is 25 °, and the highest is 35 °. Only for chains for longitudinal cutting, the sharpening angle is 10 °.

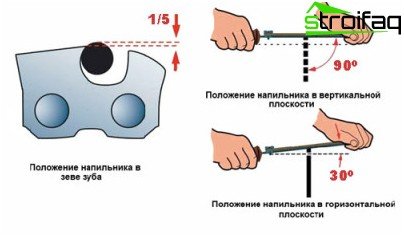

The file must be kept at a certain angle.

How to determine the need for sharpening

The frequency of manipulation depends on the frequency of use of the equipment. When working on a personal compound, the procedure may be needed only after a few months, but when the chainsaw is operated for professional purposes and three times a day it is not enough.

You can determine the working condition of the chain by its extension and the type of shavings that form when sawing. If the saw is sharpened well, the same sawdust of the correct shape comes out. If blunt, the chips are small and sharp, with a lot of wood dust (similar to sawdust formed during operation with a conventional hacksaw).

Important! The chain will blunt faster if it hits the ground. Moreover, just one touch.

If this happened unexpectedly, and you do not know where to sharpen the chain of the chainsaw, then you will have to master the skills yourself.

Sharpen the chain yourself

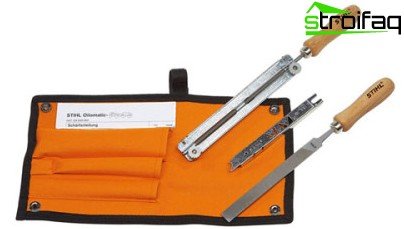

A special kit is sold for sharpening the chain at home. It should be purchased along with a chainsaw so that you don’t have to quit work and go to the city if the equipment “plows” the land.

A chain sharpening kit should be purchased at the same time as a chainsaw

You can choose the necessary tool yourself. It should be cylindrical (a holder is attached to it, which will “tell” which line to point the tool to) and flat files, a template, a hook for removing from chips. Significantly simplify the vise process (free your hands).

It is more convenient to process teeth through one. First, the cutting is sharpened. For this, a template is superimposed. Its arrows should indicate the direction of movement of the chain. When sharpening, you must press the front part, making a slight bias to the surface of the tire. Movements should be made easily and measuredly, by the same number of times for each section. One tooth should be sharpened on the left, the other on the right.

Important! If the length of the teeth is different, grind everything to the length of the shortest.

The position of the cylindrical thin file should be such that its edge protrudes slightly beyond the upper face of the tooth and is at right angles.

To grind off the stop tooth, use a thin file. The template should not be neglected. The marks on it will tell you how to sharpen the chain of the chainsaw correctly so that excess waste does not appear and the vibration does not increase:

- S (Soft) defines the angle for working with softwood;

- H (Hard) – with hard or frozen rocks.

During the sharpening of the teeth, their internal holes become wider. It is this parameter that does not affect performance, but the base of the holes should be horizontal.

How to increase the interval between sharpening

Even if the work is debatable and not as tiring as the first time, you still need to take all measures to less often engage in this procedure without compromising the normal functioning of the equipment.

- Run a new chain before use. To do this, after installation, you should run it for 1 minute at low speeds and the same amount at medium. Such manipulations will provide lubrication of all parts with oil, warm the sprocket and chain. It will also be possible to check the tension. If necessary, adjust it must wait until the tool cools down, and after the necessary actions, warm up again idling.

- Do not use the new chain with the old drive sprocket and vice versa. Change sprocket after sewing two chains.

- Constantly monitor chain tension. Stretched can slip and injure the operator.

- The depth gauge for cuts must always be filled and adjusted. This must be checked every fourth sharpening..

- Ensure a constant supply of good quality and sufficient oil for the chain, guide rail and sprocket. They must be lubricated constantly..

Choose a sharpening machine

But even a good master can not always do in a manual way. If a chainsaw is used without attaching importance to the sharpening of the chain, its cutting edge becomes completely shapeless. Then it is more rational to use the machine. They come in several forms.

With this device, you can sharpen one tooth in 3 movements

- A manual machine is more a tool for sharpening chains for chainsaws than a machine. Its working part resembles a beam saw. Only instead of the cutting blade a long cylindrical file is inserted. The configuration mechanism is quite complex, but it allows you to set all the necessary parameters. For processing one tooth, 2-3 movements are enough.

- Electric equipped with an abrasive disc. The tuning system allows you to accurately set the chain at a certain angle, brings the disk to the sharpened edge. A protective shield can be added to prevent sparks and chips from entering the eyes..

The electric machine provides high precision and quick work.

An automatic chain sharpening machine will do the job best. But not always there is such equipment and an experienced specialist who can quickly carry out the work. The process of mastering the manual sharpening method will take some time, but the skills will remain “for life”: the personal chainsaw will always be in perfect condition, and the neighbors will seek help or advice.