Modular stairs

The construction of a suburban 2x-3x-story mansion or townhouse, even a small attic, makes it necessary to build a staircase. The design, providing comfortable safe movement, performs at the same time a decorative function. Natural requirements for it are not only aesthetics and reliability, but also the ability to create the optimal configuration. Because most people prefer to install modular stairs to the second floor or in the attic: they correspond to the entire list of consumer requests. In addition, it is possible to build a simple architectural element consisting of modules without resorting to the services of builders.

Content

- Reasons for Popularity – Benefit Overview

- Varieties of construction and various assembly methods

- What is a modular staircase?

- Types of modules and their differences

- Types of supports for modular stairs

Reasons for Popularity – Benefit Overview

Modular staircases were invented in the 80s of the last century in Italy. After starting in the domestic market, they almost immediately began to actively displace massive analogs from concrete and other materials.

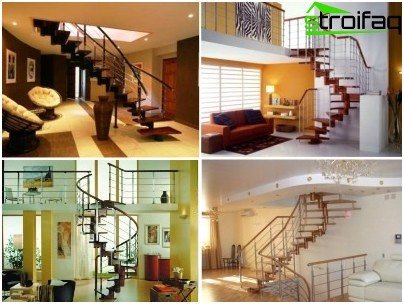

Modular stairs to the second floor, in the attic or in the living room, are built in suburban mansions intended for permanent residence, in two-level apartments, in dachas

A reasonable explanation of popularity is in the list of benefits, this:

- affordable for most fellow citizens;

- the ability to independently install, build modular stairs with your own hands, without the skills and any experience;

- successful compatibility with the overwhelming majority of finishing materials and interior elements;

- the ability to assemble from modules a straight, U-shaped, screw, angular and design combining several configurations;

- arrangement of rooms with any ceiling height.

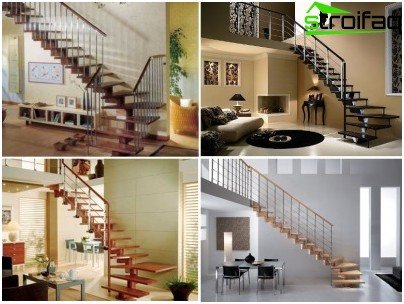

Modular stairs – photo of the options for using different components: steps, fencing elements, handrails

The modular principle allows owners to choose the option of handrails and additional elements that is optimal for them, in a number of modifications it allows you to vary the height of the steps, adjusting this size to the physical parameters of users.

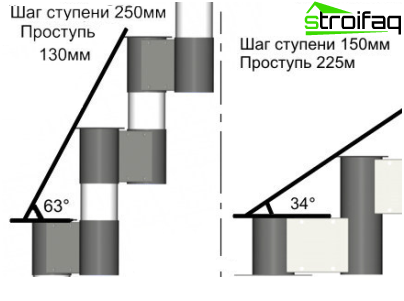

Modular constructions can be adjusted to the physical parameters of users by varying step sizes and treads

Varieties of construction and various assembly methods

Stylish, you can say, elegant modular stairs for a country house – the best option, combining strength with reasonable space savings. Universal systems are suitable for arranging presentable living rooms as well as domestic premises. They are attracted by the simplicity of design and simple mounting technology.

What is a modular staircase?

“Modular” is a defining word expressively characterizing a concept. A modular system is assembled from compatible parts, the first and last of which are attached to the ceilings and take on all the burdens of the main load. Between them there is a strong metal frame (chain or spinal slant), it is designed for the installation of steps.

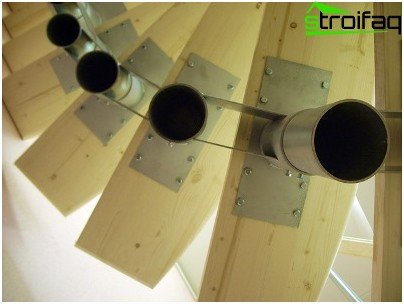

Modular staircase assembly: top view to understand the modular connection principle

Note. On the first module attached to the base or to the landing, a “guide” step is required.

The calculation of the number of average modules is made based on the distance between the floors, the geometric parameters of the structure and the given angle of inclination, according to which the installation of a modular staircase with a U-shaped, straight or angular geometry will be carried out. The height of the screw structure is calculated based only on the indicators of the distance between the floors.

Types of modules and their differences

To make modular joints, pipes from heavy-duty steel alloys are used. In fact, the most crucial stage is the construction of the frame, that is, the sequential installation, combination and careful fastening of modular parts and supports in a kind of “ridge”. Steps are attached to a correctly mounted frame, for the production of which both expensive and cheap types of wood are used. Then the balusters and handrails are mounted, they can also be made of expensive or budget materials.

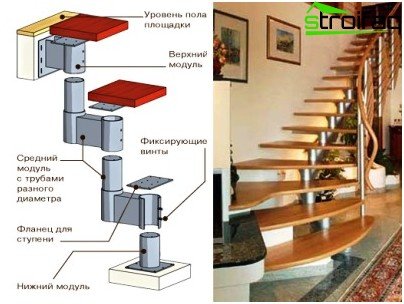

A module is a component of a ridge body that is sequentially assembled from these elements and looks like a ridge

High-quality assembly of a modular staircase guarantees the durability of the construction service and operational safety. This process requires scrupulous compliance with the briefing attached to the finished set and responsible execution. There are three types of modules for the construction of stairs, depending on which the assembly and connection is performed.

- Cast or welded module, on two opposite sides of which are pipes of different diameters and different heights. After combining the long pipe of one module with the short pipe of the next element and installing it in the position required by users, the connection is fixed by tightening the screws.

Modular staircase for a summer residence, a country house with fixing screws

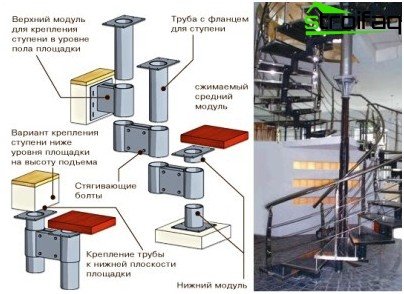

- A module consisting of two separate components: a welded part with two short pipes on the sides and a long pipe equipped with a flange (flat plate) for attaching the step. On the jumper of the part with two side pipes, there are holes for tightening bolts. Most often, a modular spiral staircase is constructed according to this scheme, since similar modules can be rotated relative to each other, as you wish.

Design with clampable modules – the best option for the construction of a spiral staircase

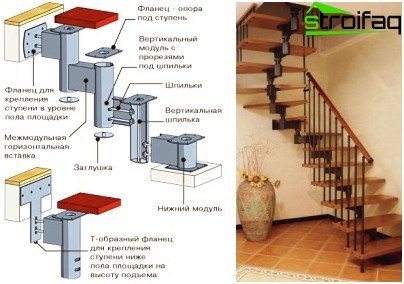

- A module of a large number of individual elements that do not have welds. Parts are interconnected using threaded rods. This is the most difficult option to install, but the most aesthetic, since all the hardware is hidden inside the kosour.

A modular kosour, the elements of which are connected by studs, all the fasteners of which are hidden from view

There are also wooden modular systems, the symmetrical components of which are equipped with holes on both sides for installing metal studs in them.

Types of supports for modular stairs

Universal metal modular stairs must have supports, which are used as:

- intermediate pipe-racks based on the base, they are installed every 4 to 7 modules, depending on the design features;

- brackets, which are mounted to the supporting wall.

The frame of the modular ladder must have support legs or lean on the bracket

Do not use supports only when one edge of the step rests on the wall to which it is attached using a corner or anchor.

We delve into the details of installation work

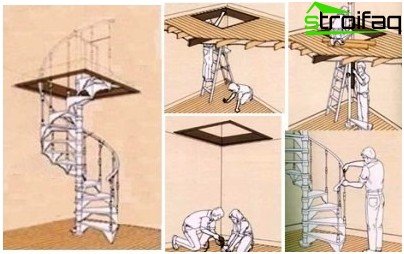

When choosing modular staircases for summer cottages, owners predominantly prefer screw structures that occupy a minimum of usable space. The technique of their construction cannot be called extremely simple, but a person who knows how to use an instrument, a head and instructions to cope with installation is able to. However, for the implementation of the assembly he will need a partner. Work sequence:

- Determine the location of the central support, which is a vertical rod. To do this, diagonally pull two cords in the opening of the upper floor, to which the staircase should lead. A plumb line descends from the point of their intersection, it will indicate the installation location of the thrust flange (II design).

- We mount a persistent flange, the center of which should coincide with the found point. Fixing is done with screws attached to the kit through the holes provided for them.

- Determine the position of the first “guide” stage, placing it first on the floor. After that, the step must be put on the fixed flange together with the baluster already installed on it. Then we insert the central support-rod into the flange through the first stage.

Attention. The vertical installation of the central rod must be checked after the installation of the first and each subsequent stage.

Mounting a modular screw structure: the first point for installing the bottom flange with the module is sought by crossing the cords diagonally and plumb

- The next step on the vertical rod should be put on and help to lower the partner located in the floor opening. Further in a similar sequence. All steps must be firmly screwed into place specified by the manufacturer..

- Having completed the installation of the total number of steps, we mount the landing on the rod and fasten it to the walls of the opening.

- The final touches – fastening the elements of the fence, handrails and decor, if any.

Compact modular staircase photos demonstrate in a variety of variations. Perhaps, in general, there are no such premises that it is impossible to equip them with their help. Carefully fulfilling all the points of the instructions, everyone can provide a reliable, solid staircase to their country house.