DIY spiral staircase

In a small country house or a two-level apartment, beautiful and compact spiral staircases often remain the only means of moving people between floors. But in a spacious house, a neat spiral staircase with your own hands will become an alternative to the main entrance with a bridge connecting living quarters of different floors with each other, as well as with those located in the basement or in the attic of the building. She loses a little in the comfort of a direct flight of stairs, but takes up much less precious usable area, it requires less building materials to build, but before you make a spiral staircase yourself, you need to understand several rules for the construction of these structures.

Content

- Types and design options of spiral staircases

- How not to miscalculate the size when designing?

- How to calculate the design and make it ergonomic?

- Technological features of self-assembly

Types and design options of spiral staircases

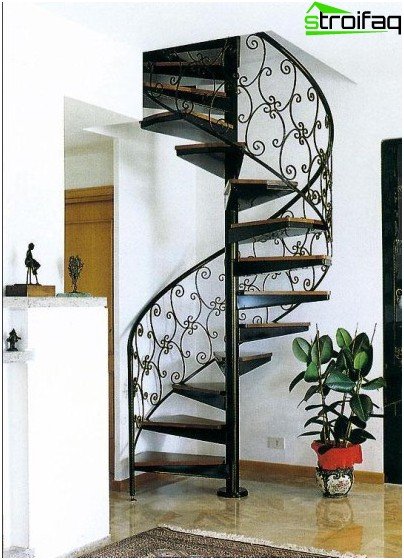

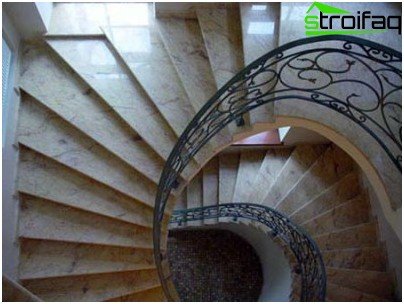

From the point of view of external attractiveness, a brighter interior element is hardly found than spiral staircases: photos of fancifully wriggling beauties from a variety of materials do not leave anyone indifferent. Here, traditional wooden and solid stone, and openwork forged spiral staircases and exotic designs made of transparent glass or bright plastic – everyone is free to choose depending on taste, interior style, imagination and financial possibilities.

With a huge variety of design solutions, all spiral staircases are one of four types

But, despite such a diverse design of spiral staircases, they can be structurally divided into four main types:

1. A spiral staircase, the wedge-shaped steps of which rest with the wide end on the surrounding walls, and narrow – on the central support column or pillar of stone, wood or thickened fragments of steps. Steps are often attached to the walls on bolts, but there are options on spiral bowstrings or braids.

The first type is a spiral staircase supported by a central pillar and the nearest walls

2. A freestanding spiral staircase remote from the walls with steps cantilevered on a monolithic central support pillar.

The second type is a spiral staircase remote from the walls with steps cantilever mounted on the support column

3. Spiral staircase without central support pillar. The steps are supported by spiral curved bowstrings or kosour, which smoothly pass into the supporting railing. This is a very beautiful, sophisticated, but also the most difficult spiral staircase construction to manufacture, requiring the experience and professionalism of a craftsman .

The third type is a spiral staircase without a central pillar with support on spirally curved bowstrings. Beautiful but complex construction

4. A spiral staircase with a central support rod, as a rule, representing a thick-walled steel or asbestos-cement pipe with a diameter of at least 50 mm. This is a traditional, most common staircase construction, easy to manufacture and reliable in operation. After installation, the central pillar and stairs can be painted or finished with wood, ceramics, etc..

The fourth type is a reliable and easy-to-perform metal spiral staircase with support on a monolithic pillar from a thick-walled steel pipe

Taking into account the peculiarities of manufacturing and installation, a metal or wooden spiral staircase with their own hands is the best option for a skilled homeowner who seeks to equip his home without assistance. On specialized Internet sites you can find ready-made designs of spiral staircases, which you can quite use, making the necessary calculations to bind the structure to your specific room.

How not to miscalculate the size when designing?

It is known from practice that spiral staircases with a span width of at least 800-900 mm are most convenient in operation. That is, the diameter of the entire staircase structure should be at least 2000 – 2200 mm, taking into account the diameter of the central pillar and the width of the stairwell in the floor, into which the staircase and its railings with handrails should freely enter. In terms of spiral staircase design can have a round, polygonal, oval and even rectangular shape.

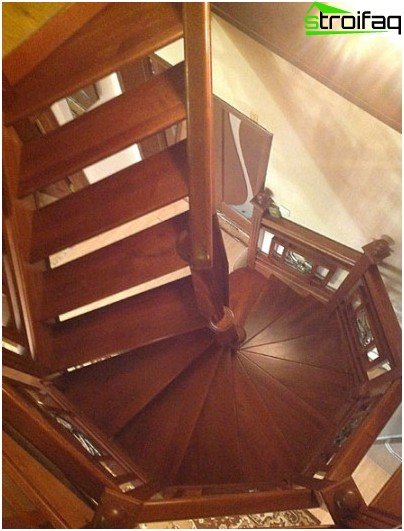

In plan, a spiral staircase can be not only round, but oval, polygonal or quadrangular

In residential buildings with a low traffic intensity, the diameter of the auxiliary spiral staircases to the basement or to the attic is quite acceptable within 1400-1500 mm with a tread width of 550-600 mm. Making a spiral staircase with a diameter of more than 3000 mm is not advisable: with an appropriate opening size, it is better to install a more comfortable and safe marching staircase.

note!

The design of the stairs with steps mounted on the central support is the least expensive, and the construction of a spiral staircase with the steps attached to spiral curved bent-glued bowstrings is more complicated and will cost much more.

How to calculate the design and make it ergonomic?

If a spiral staircase will be used as the main one, the width of its span of less than 800 mm is undesirable, as it will not allow two people walking towards each other to disperse. When calculating the size and number of running stages, the same principles are used as for similar calculations for direct marching stairs:

- the depth of the step in the midline is not less than 200 mm;

- depth of a step at a distance of 150 mm from a support rack – not less than 100 mm;

- the depth of the step in the wide part at the edge of the stairs is not more than 400 mm;

- the diameter of the stairs – 1300 – 3300 mm;

- diameter of the passage along the inner edge of the railing – 1200-3200 mm;

- march width – 530 – 1430 mm;

- the diameter of the opening in the ceiling – 1300 – 3300 mm.

Typical dimensions of a spiral staircase 1 – march width 2 – diameter of the staircase along the outer edge of the railing 3 – diameter of the stairwell 4 – diameter of the passage along the inner edge of the railing

An important design parameter in the design of a spiral staircase is a height that is comfortable for a person. We give a calculation for a ladder with a height of 3000 mm and a march width of 800 mm.

The diameter of the stairs is equal to twice the march width plus the diameter of the support column (200 mm):

D = 800 x 2 + 200 = 1800 mm

The radius of the rise is equal to the sum of half the width of the flight of stairs and the radius of the support:

Rn = 400 + 100 = 500 mm

Using the formula for the circumference of the school course of geometry and the average value of the tread depth of 200 mm, namely dividing the length of the trajectory of movement by the tread depth, we calculate the number of steps in one turn of the staircase structure:

L = 2 πr: 200 = 2 x 3.14 x 500: 200 = 17.2

Rounding off the obtained value, we determine that one turn of the spiral staircase should consist of 17 steps. Most often, the staircase consists of one turn, but may contain several.

Ergonomic step height is calculated so that the total height of one turn of the spiral provides a convenient and safe movement of a tall person. To calculate the height of 180 cm, add the operational 20 cm and divide by the number of steps in one turn. The calculated step height is obtained:

h = 2000: 17 = 120 mm

We determine the required number of steps for a spiral staircase with a height of 3000 mm:

n = 3000: 120 = 25

Thus, to ensure convenient movement, a spiral staircase with a height of 3000 mm and a march width of 800 mm should contain 25 steps with a height of 120 mm.

Some useful rules that will make the spiral staircase durable, safe and convenient:

- The exclusion from the design of the spiral staircase of risers increases its safety, since the leg is firmly supported by the step and does not slide off it even in a narrow part.

- With a passage height of at least 2000 mm, a comfortable and safe movement of even a very tall person is ensured.

- To place and rigidly fix the support strut of a spiral staircase, you should choose a place that can support the weight of the structure and a minimum of two to three people.

- The placement of the steps with an overlap of several centimeters relative to each other provides comfort of movement, and also further strengthens the entire structure by installing a bracket between the front and rear edges of the extended part of two adjacent steps.

Technological features of self-assembly

Armed with calculations, you can buy in the store workpieces of steps of standard sizes 400 x 800 mm or 300 x 1100 mm and a thickness of 40 mm, cut wedge-shaped steps from them in accordance with the project and proceed with the installation of the stairs. First you need to install and firmly fix the support column, and then fix the steps on it.

For those who do not trust the calculations made independently, there is a more convenient option – ready-made prefabricated spiral staircases from domestic or foreign manufacturers, which are easily assembled according to the manufacturer’s instructions.