Metal stairs

Metal, as a building material for the manufacture of stairs, against the background of other options, distinguishes the optimal bearing capacity and operational long-term. Its technological qualities make it possible to create small-sized lightweight structures with a configuration of any type and complexity; metal stairs fit perfectly into almost any interior composition. They are installed both inside and outside the building, leading to the household and central presentable rooms.

Content

- Classification of stairs made of metal

- Design differences, types

- Combination Variations

An additional plus is that the simplest welded staircase made of metal can be made independently, and having gained experience and skills, proceed with the manufacture of an exclusive building with your own hands.

A metal welded ladder – if you wish, a completely feasible idea that requires elementary skills in welding, you can get them in a few practical exercises

Classification of stairs made of metal

According to the design features, the stairs are metal: the external and internal are no different from analogues made of concrete and wood. According to typical norms and rules, projects are drawn for them, and the most rational form is chosen. According to the manufacturing method, they can be forged and welded. The forging technique, of course, needs to be mastered for too long, but a few practical lessons are enough to get welder skills.

Design differences, types

The most common types, the design of which can be implemented with your own hands, include:

- structures with metal braids – a kind of ridges, to which steps are mounted;

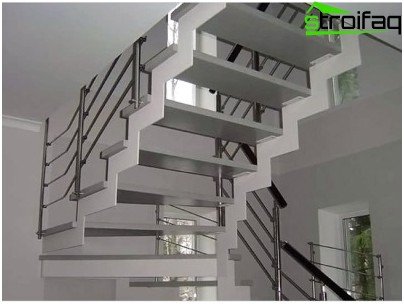

Metal stairs: structures with one support beam – kosour

- stairs made of metal on bolts – structures without frames, consisting of separate steps attached to a supporting wall with the help of special bolts;

Metal staircase, individual elements of which are bolted to the wall

- structures on inclined load-bearing beams – bowstrings, between which treads and risers are located or only treads;

Staircase with two side load-bearing beams – bowstrings

- spiral staircases with spiral staircases and a supporting central column;

It is better to entrust the manufacture of a spiral staircase to specialists or assemble it from ready-made factory modules

- prefabricated metal stairs, consisting of modules made at the factory, their construction process resembles the assembly of a simple children’s designer.

A metal structure can be supported only by ceilings. To increase reliability, supports can be installed under the staircases, under the segment of the staircase with running steps.

The site of a metal welded staircase with a support made of a metal pipe

The platforms can also be fixed with consoles, and the racks can be hidden in the wall. The function of the supporting element under the metal staircase can be successfully performed by a concrete or brick specially built interior wall.

with your own hands you can weld not only the frame, but also build a brick supporting wall under it

Combination Variations

Technological durable material works wonderfully with any type of finish, with wood, concrete, brick, natural stone, glass and its organic counterpart. Any kind of fencing can be equipped with metal stairs: the photo shows how wonderful the buildings look with standard vertical balusters and traditional handrails. Instead of standard elements, parallel prokids, glass or perforated steel screens, hand forging and carved wood can be used.

Different design options for metal stairs: plexiglass fence on the left, chrome parallel prokids on the left

Note. Fencing parts can be attached to a metal staircase in two ways: mounted on a step or fixed by welding or bolts to the end of the step.

Fastening of the fence elements to the end of the steps, based on a sawtooth bowstring made of sheet metal

Depending on the operational specifics and the dictatorship of the style, the supporting metal elements can be supplemented with steps made of concrete, expanded metal, porcelain stoneware, reinforced steel, corrugated iron, etc. In the hall of a country house, a metal staircase with wooden steps, built on original design. Its more modest counterpart will successfully provide communication between domestic premises or help arrange a separate entrance to the attic.

Metal staircase with wooden steps: the option of fastening vertical balusters with bolts

The staircase installed outside the building can be completely metal, but the means of internal interfloor communication created from metal alone will not please users with pleasant tactile sensations and warmth. Inside, it is advisable to use the finish. Moreover, a metal staircase can be equipped with not only standard varieties of steps, a carpet, a wear-resistant laminate, parquet dies, and facing ceramics are quite applicable.

Features of self-construction

For manufacturing, you will need a welding machine, a mechanical saw and an emery wheel for deburring. If wood sheathing is supposed, then also a circular saw, clamps for temporary joining of parts and drill bits for metal to form holes for self-tapping screws.

According to the project created in advance, the implementation of which can be read in the corresponding article, it is calculated how many meters of metal profile, pipes, steel sheets and reinforcing steel are required. It should be noted that a worthy metal staircase with your own hands will be welded after a series of practical exercises, the course of which can also be followed independently by video and description.

Using a compact apparatus for electric arc welding, durable welds are made, turning the structure into a monolithic structure with equivalent strength characteristics at any point

For the manufacture of load-bearing beams (kosour or bowstring), it is recommended to use a channel, an I-beam is suitable, corner steel is quite suitable, pipes with a rectangular section.

Elementary construction example

This simplest staircase made of metal with your own hands will be constructed from a channel placed on the edge with sizes of 8-10. If further cladding is expected, sheet metal can be used to make the steps, relief sheets will be required for steps of external structures, pressed pressed metal flooring or similar material with anti-slip properties. For fences, angular steel will be needed, reinforcement for tread supports.

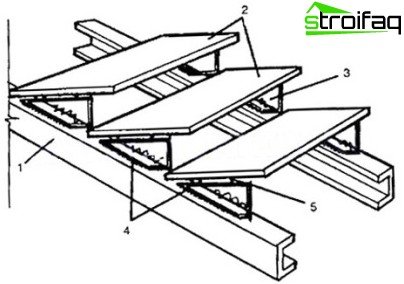

Scheme of a simple metal staircase with supporting beams from a channel to which fillets made of reinforcement are welded

- From reinforcement, it is necessary to make filly according to the design dimensions – supportive devices congruent to each other, mounted on a beam.

- To that part of the filly, on which the step “lies” directly, it is necessary to weld the brackets for fastening.

- The fillets must be welded to the channel placed on the edge according to the exact marking made in advance.

- In order to achieve complete identity, it is recommended that the second channel be attached to the channel beam with the fillets already welded and correct the marking in case of deviations. Pay attention. To create a staircase with a standard width of up to 1 meter, it is enough to make two braids or bowstrings. A wider structure needs to be equipped with three or more beams.

- Then all the components of the metal ladder are assembled together by means of electric arc welding, if everything is made of metal or by installing wooden steps.

- The finished structure must be treated with soil and coated with a composition that protects against corrosion.

The supporting parts for attaching the steps can be racks welded from the channel, metal corners welded to the supporting beams.

Variants of devices for installing steps welded to the supporting beam: on the left – welded from the channel, on the right from the rolled steel

A more complicated option is the manufacture of metal stairs with a sawtooth bowstring cut out of thick sheet steel. It is necessary to cut, very carefully, carefully observing the dimensions.

Technology of a covering of steps by a tree

Suppose it is decided that the outer metal staircase will be equipped with wooden linings for treads. Before plating, you must evaluate the likelihood of laying additional fasteners.

- On metal steps, the location of holes for self-tapping screws or bolts with washers is marked, a frequency of 15 cm. At least 2 cm should deviate from the end of the hole..

- To metal treads, a plywood substrate is mounted. Its fastening is carried out using a specific mounting adhesive with a filling effect, it does not crumple after solidification. The glue filling the voids will help eliminate defects that are inevitable even with high-quality welding. It is impossible to fix the substrate on the mounting foam, as it is not crumple resistant.

- With two clamps, the wood lining is fixed on a metal tread and fastened with self-tapping screws through drilled holes from below into the underfloor or open with bolts and screws.

Metal staircase with wooden steps: the fastening of the wood elements in the “potty” is hidden from view

Having studied the simplest ways and learning how to weld a metal staircase, you can safely proceed to the construction of a simple structure leading, for example, to the cellar. And then an already experienced performer will be quite capable of producing a more complex, more aesthetic design, the production of which is not a sin to brag about.